Combustion exploitation method for thin-layer and deep-layer original heavy oil reservoir

A production method and technology for heavy oil reservoirs, which are applied in the fields of production of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of high pressure, high temperature, and high risk of wellbore damage in the ignition stage, and achieve low fuel consumption, The effect of high oil production speed and saving ground investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

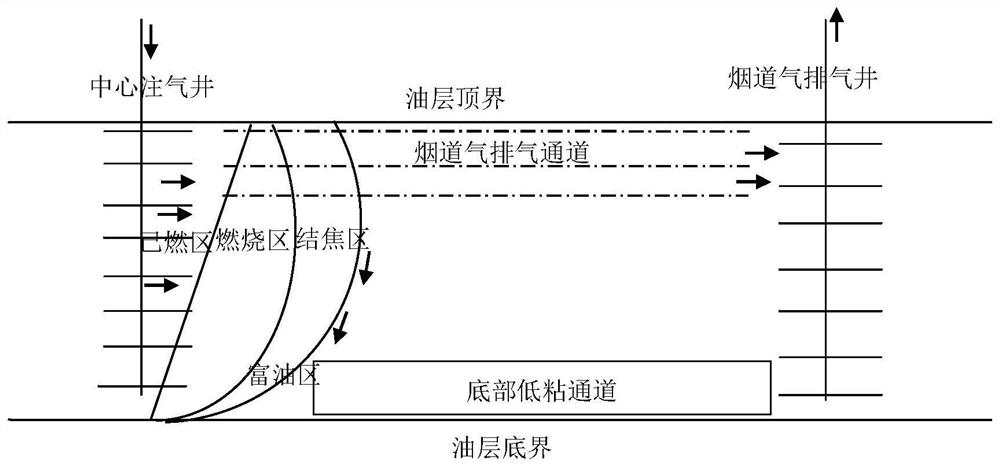

[0078] In this embodiment, the following thin layer, deep original heavy oil reservoir, specifically includes the following steps:

[0079] The reservoir is an unjustible heavy oil reservoir, which has a depth of 1400m, and the oil layer is effective in thickness of 12m. The formation pressure is 14 MPa, the formation temperature is 65.4 ° C, the average crude oil viscosity at the oil layer is 7000 MPa · S, the oil-containing saturation is 75.0%.

[0080] S100, deploy anti-five-point well network, and the well is a straight well, and the well distance is 35m.

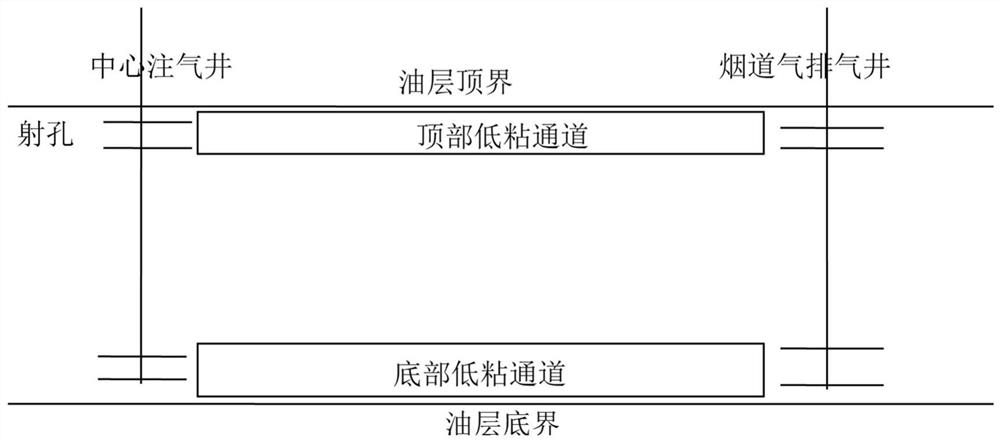

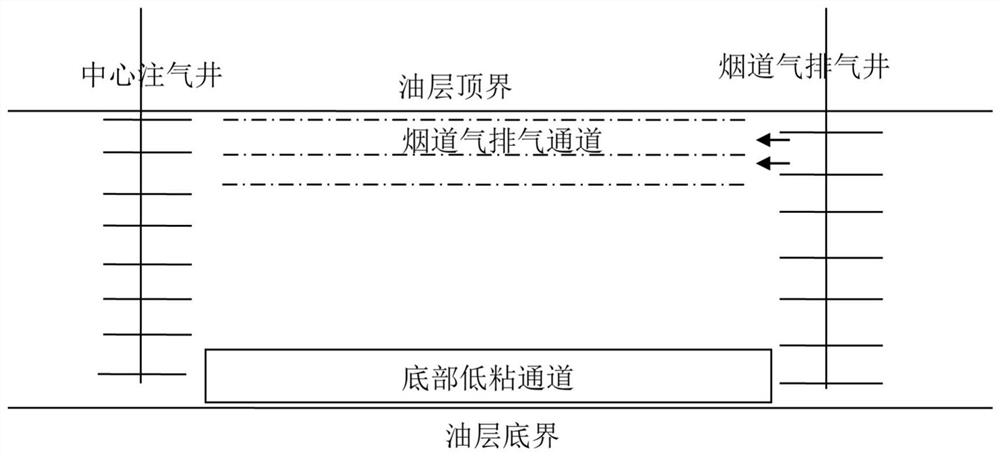

[0081] S200, establish a low-bonded channel and bottom low-bonding channel

[0082] like figure 1 As shown, in the bottom of the injection well and the exhaust well, the bore of the exhaust well is first, and then synchronized (0.5 times the injection pressure below the minimum main stress), the control (below 50m) 3 / d) Tone adhesive (which can be organic substances such as light hydrocarbon, ketohyde acid lipidyl ether, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com