Downward single-drift type layered filling mining preparation layer arrangement method and arrangement structure

A layer layout and road type technology, which is applied in the field of preparation layer layout method and layout structure of downward single-entry layered filling mining, can solve problems such as easy instability and collapse, low operation safety, and difficulty in roadway formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

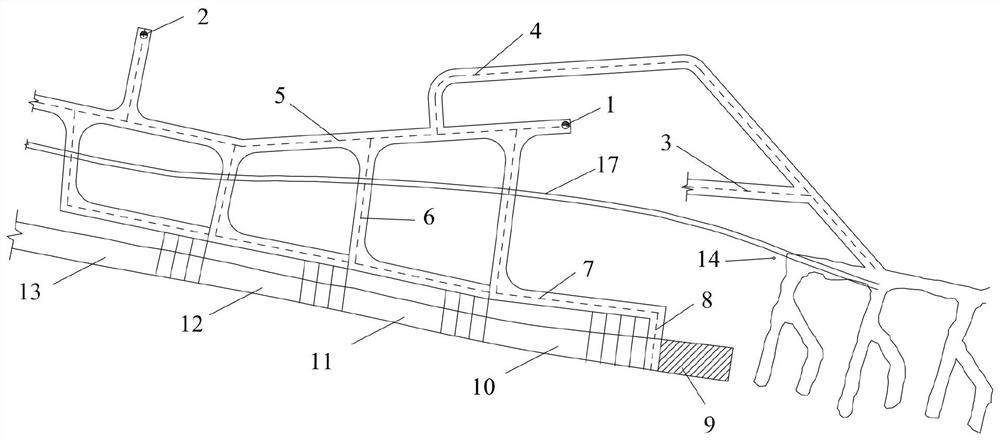

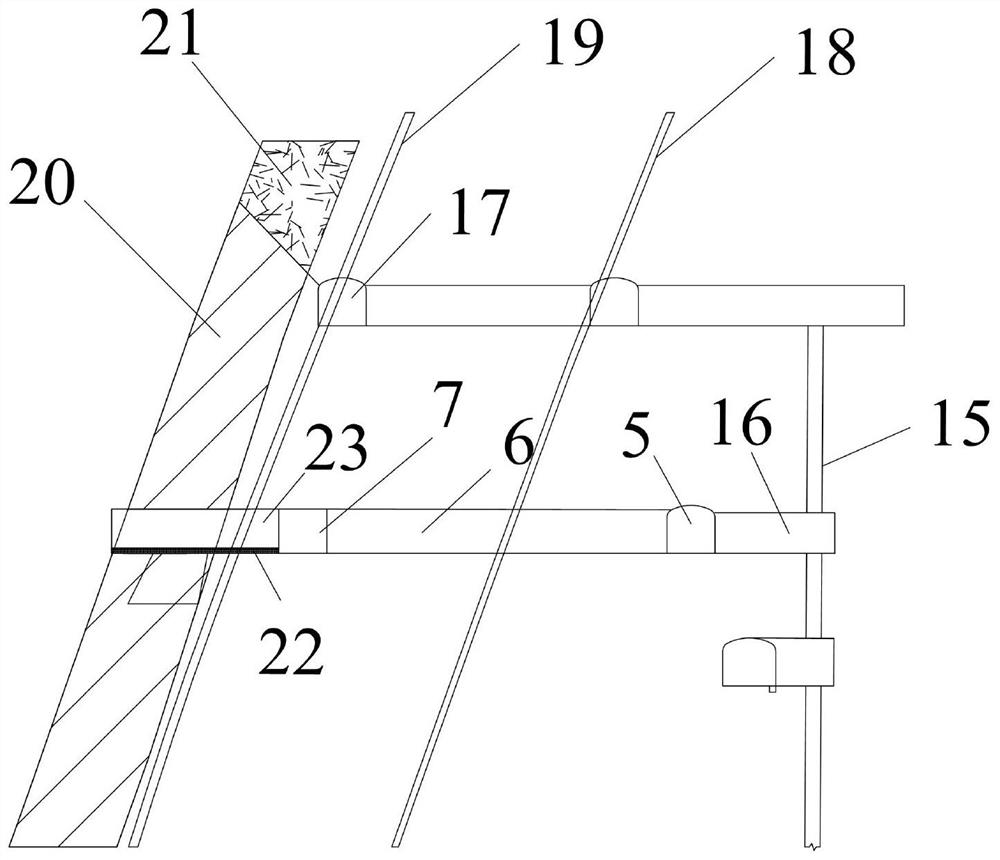

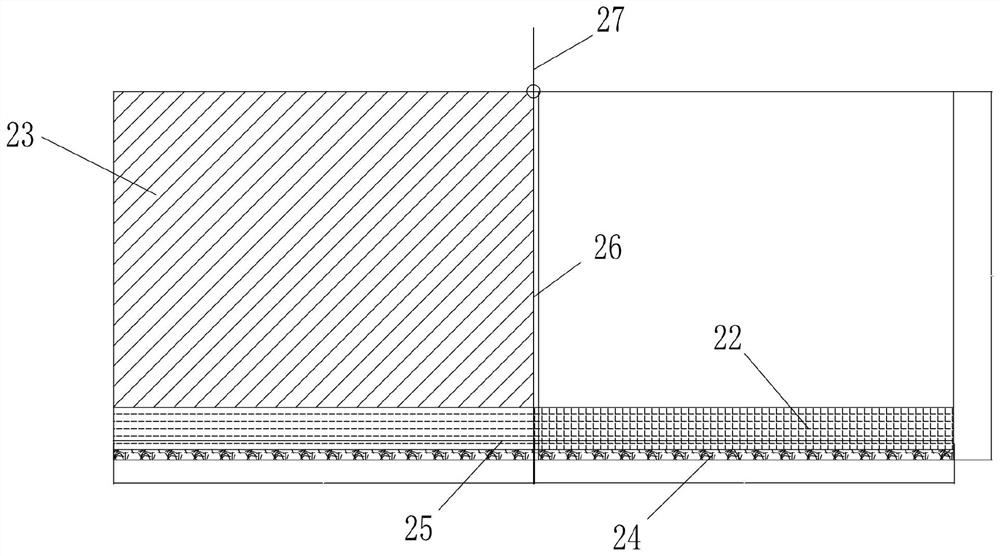

Embodiment 1

[0066] The 770-878mL section of a copper mine has an average dip angle of 70° between the 2040-2700 exploration line, the thickness of the ore circle is 6m at a grade of 1.5%, and the geological grade of Cu is 2.81%. There is about 2m thick rich ore in the footwall of the ore body, and the Cu grade is 3%-6%. There are generally three to four dominant joint groups in the ore body, and the poor quality is easy to collapse. Adjacent to the footwall of the ore body is an extremely unstable and weak rock formation with a thickness of 0.5-2m. The design adopts the reinforced concrete false roof downward layered filling mining method for mining, and the preparatory layer works are arranged along the veins. During the construction process, due to the broken ore rock, the roof and side wall rocks are easy to collapse, and the working environment of workers cannot be guaranteed. In addition, , the preparatory layer project is arranged along the vein, the support strength is relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com