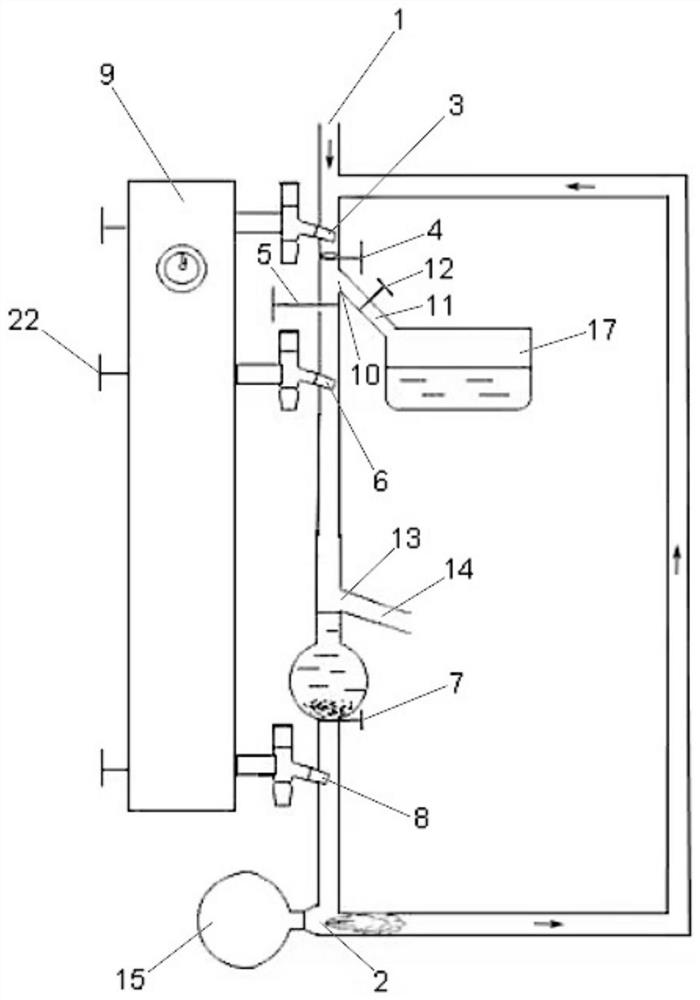

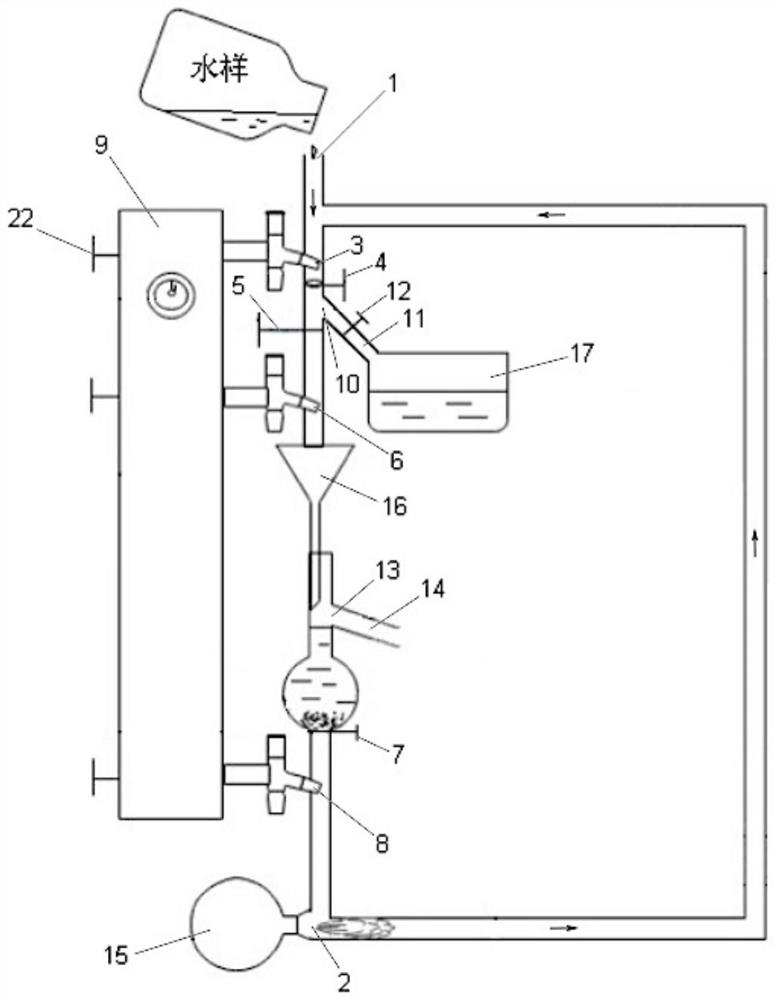

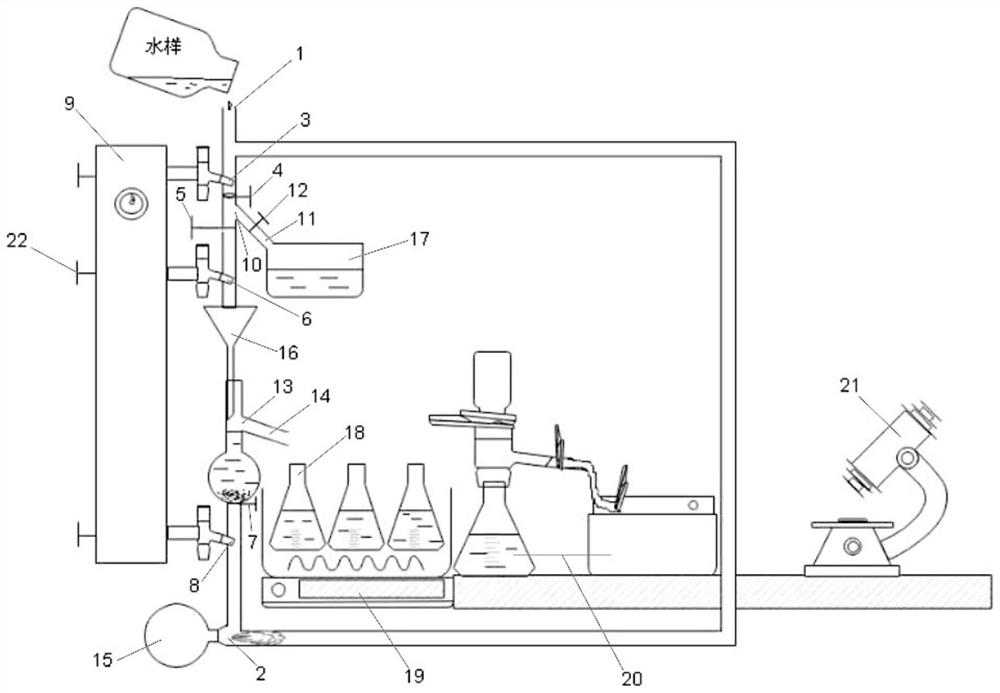

Continuous separation device for micro-plastics with different densities and application of continuous separation device

A separation device and microplastic technology, which is applied in measurement devices, material analysis by optical means, and material analysis, etc., can solve the problems of low precision, low overall efficiency, and inability to accurately determine the type of microplastics, and achieve accurate separation, The effect of avoiding loss and residue and shortening manual operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0085] In order to verify the separation effect of the continuous separation device of microplastics of different densities provided by the present invention, we first select four kinds of microplastics of known composition (detected by Fourier transform infrared spectroscopy), which are artificial fibers (1.48g / cm 3 ), polyester (density 1.38g / cm 3 ), polystyrene (1.05g / cm 3 ) and polyethylene (0.96g / cm 3 ), 20 pieces each, the size is 0.5mm-5mm, and the shape is fibers, fragments and films. Mix all four kinds of microplastics into 1L of distilled water as the water sample to be tested.

[0086] Then configure solutions with different densities: the density is 1.0g / cm 3 of distilled water (referred to as X1 solution), the density is 1.2g / cm 3 Saturated sodium chloride solution (denoted as X2 solution), density is 1.3g / cm 3 Potassium formate solution (denoted as X3 solution), density is 1.4g / cm 3 Potassium formate solution (referred to as X4 solution). Next, the continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com