Novel capacitor cabinet

A capacitor cabinet, a new type of technology, is applied in electrical components, substation/distribution device enclosures, substation/switch layout details, etc. The effect of prolonging the service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

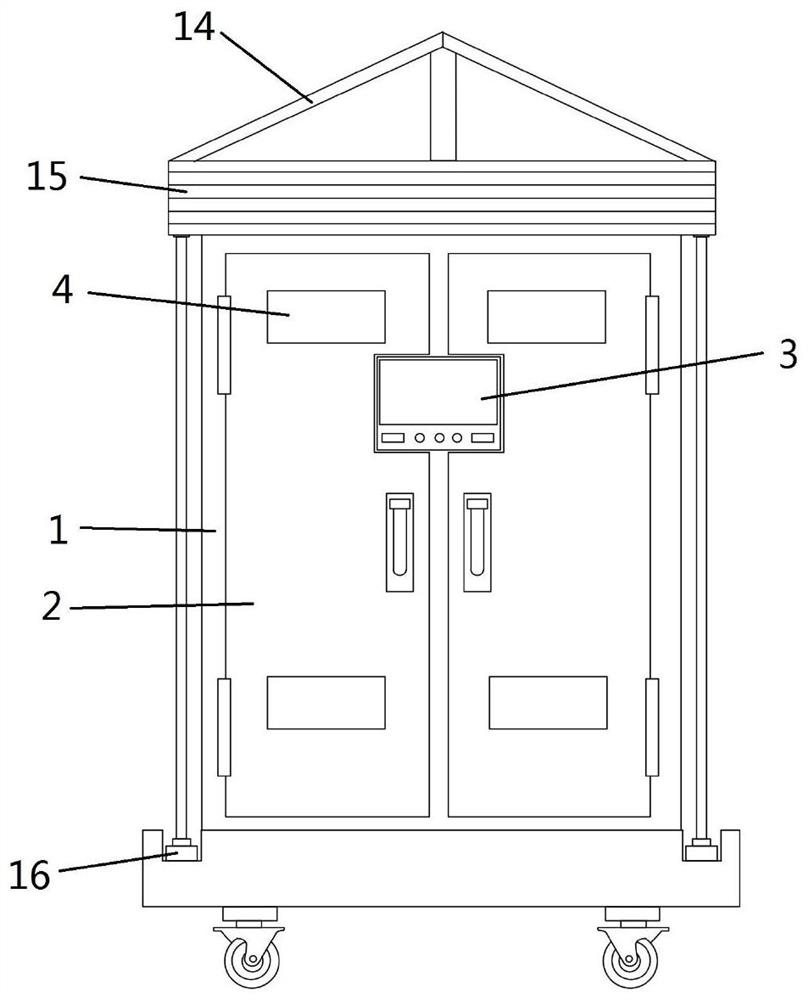

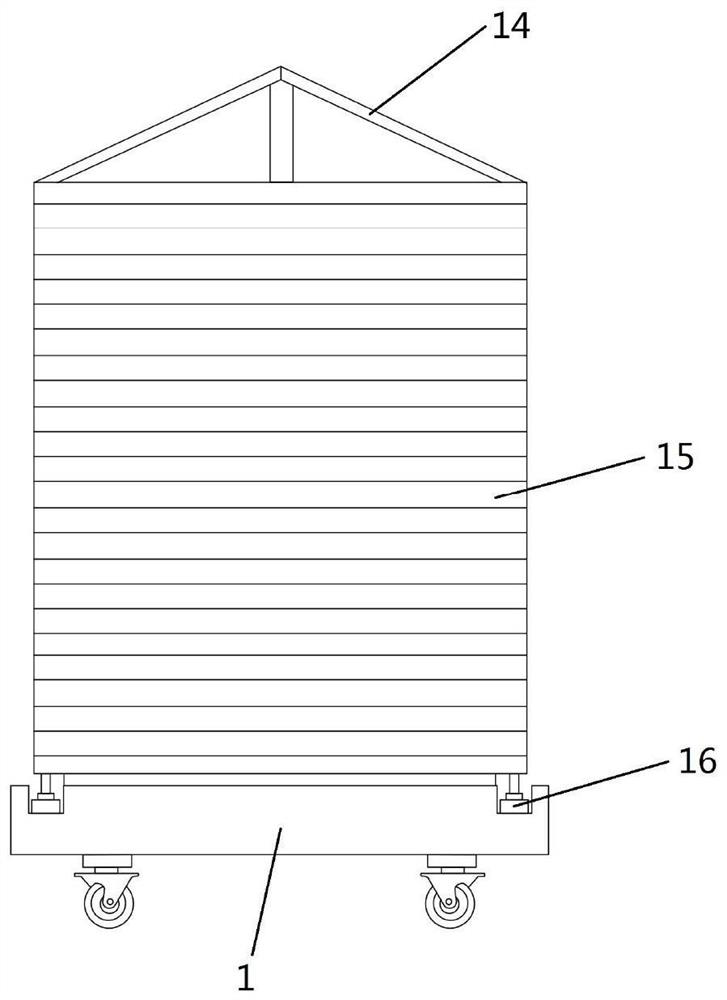

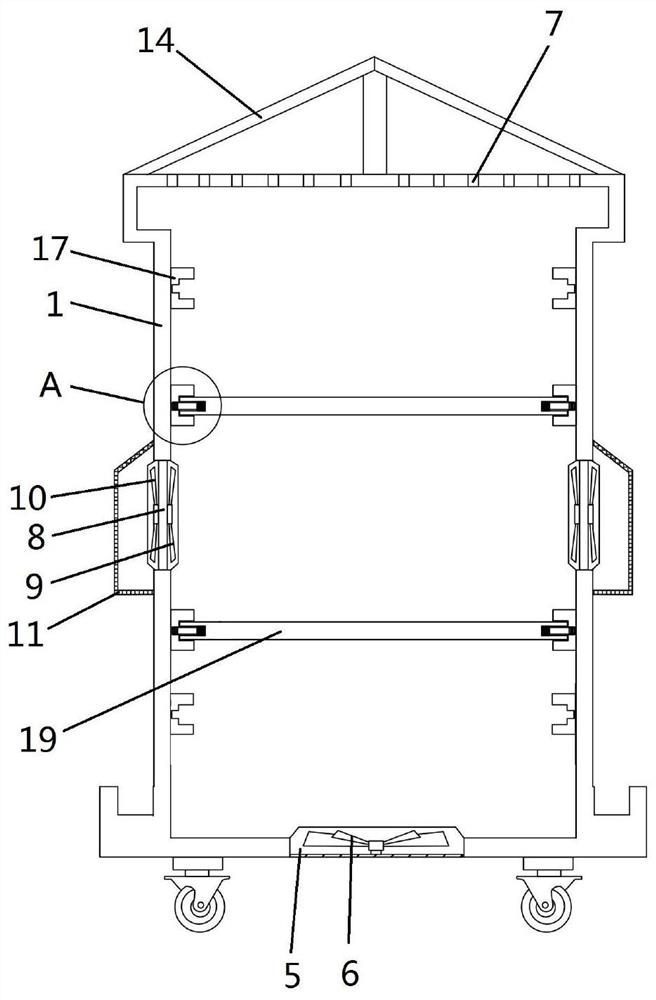

[0027] Embodiments of the present invention disclose a novel capacitor cabinet, such as Figure 1 to Figure 3As shown, it includes a cabinet body 1, a cabinet door 2 is installed on the front of the cabinet body 1, a control panel 3 and an observation window 4 are arranged on the cabinet door 2, and the inner walls of the opposite sides of the cabinet body 1 are installed sequentially from top to bottom There are a plurality of slide rails 17, and a bearing plate 19 is slidably connected between the matching slide rails 17 on both sides, and the connection between the bearing plate 19 and the slide rails 17 is provided with an elastic locking limit for fixing the two. Mechanism, the bearing plate 19 is uniformly provided with cooling holes, the bottom of the cabinet body 1 is provided with an air inlet 5, the inside of the air inlet 5 is provided with a cooling fan 6, the bottom of the air inlet 5 is installed with a dust-proof net, and the top of the cabinet body 1 is evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com