Coal slime ultrahigh-pressure dehydrator and coal slime ultrahigh-pressure dehydration machine

A technology of ultra-high pressure and dehydrator, which is applied in the field of ultra-high pressure dehydrator of coal slime and ultra-high pressure dehydrator of coal slime, which can solve the problems of limitation and increase of labor intensity, achieve breakthrough of pressure limit, improve equipment stability, and simplify drainage The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

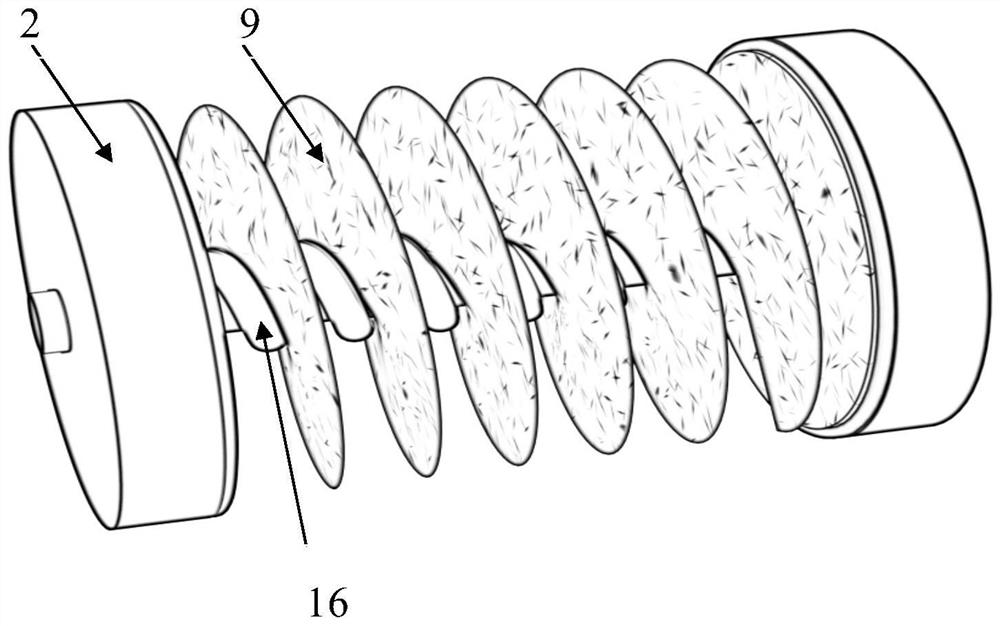

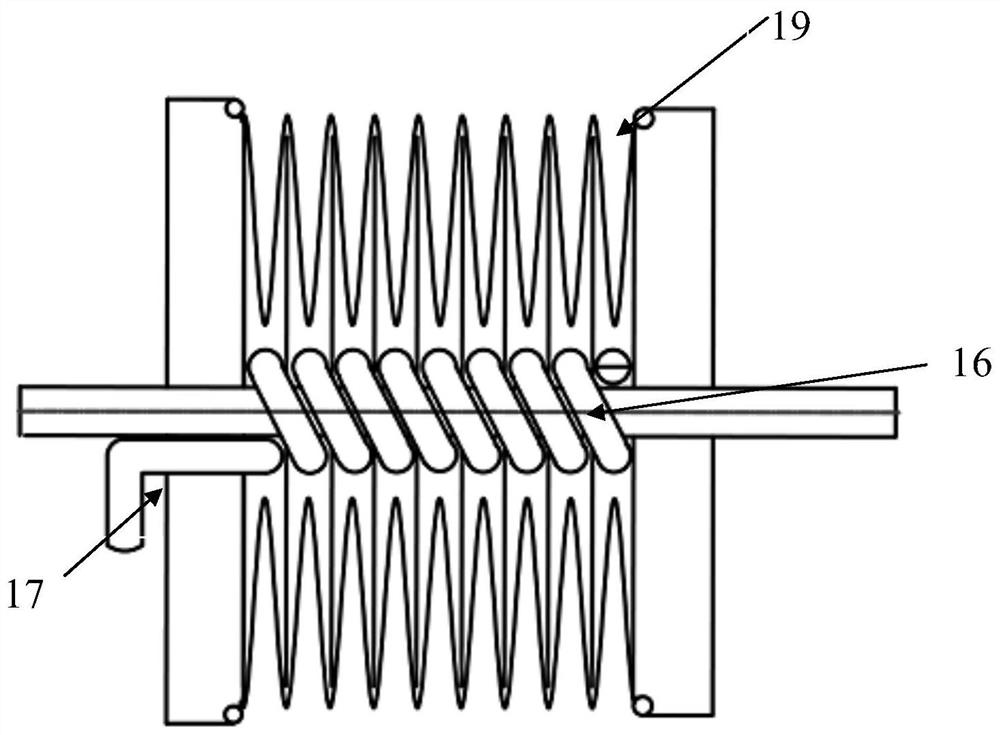

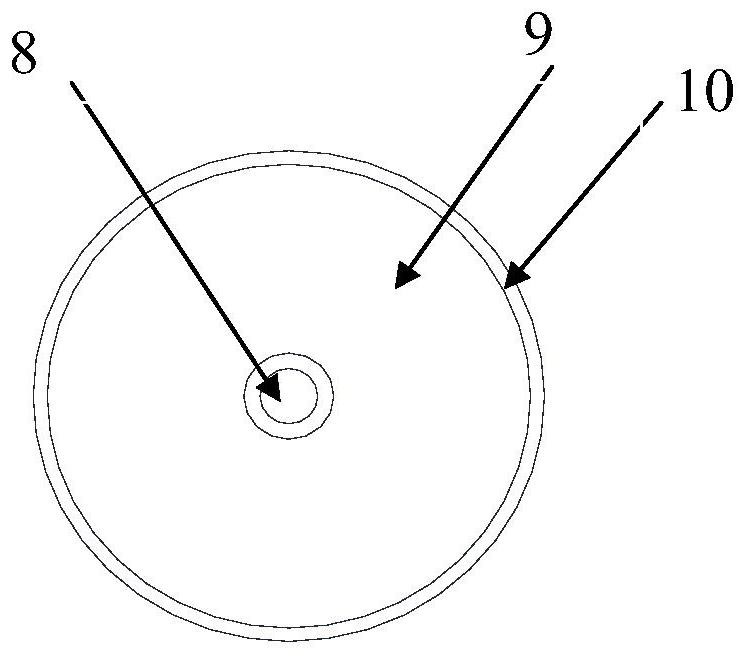

[0019] Figure 1-4 A coal slime ultra-high pressure dehydrator is shown, including a filter press container 2, a sealing piston 4 and a filter press piston 3 respectively arranged at both ends of the filter press container, and a filter press arranged in the filter press container unit; the filter press unit includes a drain pipe 8 arranged in the filter press container, a filter cloth group spirally wound on the drain pipe, and a filter cloth group spirally wound on the filter cloth group The support plate group on the drain pipe described above; the filter cloth group is formed by connecting a plurality of filter cloth bags 10; the support plate group is formed by connecting a plurality of support plates 9; the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com