Catalytic agent for removing sulfur and nitrate, catalytic agent device, and preparation, activation and regeneration methods of catalytic agent

An activation method and catalyst technology, applied in chemical instruments and methods, separation methods, catalyst activation/preparation, etc., can solve problems such as increasing maintenance costs, damage to desulfurization, and denitration equipment, saving equipment costs, reducing costs, and avoiding damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

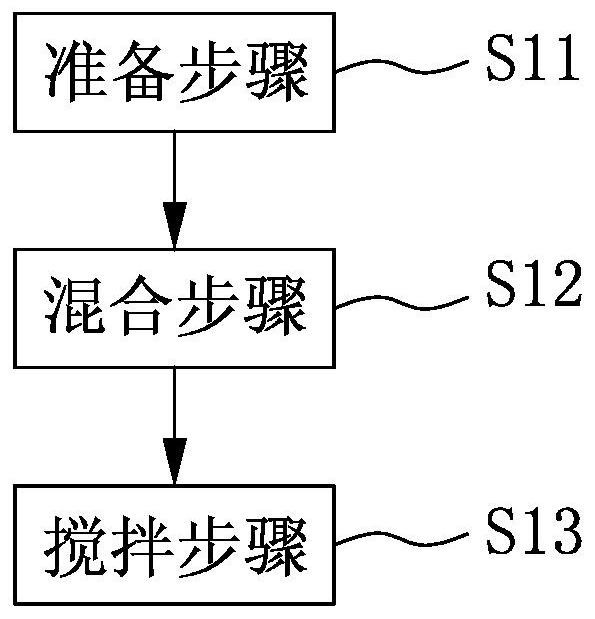

[0024] The preparation method of the desulfurization and nitration catalyst includes a preparation step S11, a mixing step S12, and a stirring step S13. The catalyst for desulfurization and nitrification includes a raw material and pure water, the weight ratio of the raw material to pure water is 1:0.75 to 1:1.5, based on the total weight of the raw material as 100wt%, the raw material includes 40wt% to 60wt% manganese acetate, 20wt% to 30wt% ferric nitrate, and 20wt% to 30wt% oxalic acid.

[0025] In the preparation step S11, the raw material is prepared first, and the raw material contains 40wt% to 60wt% of manganese acetate, 20wt% to 30wt% of iron nitrate, and 20wt% to 30wt% of oxalic acid based on the total weight of 100wt%. . In the mixing step S12, the raw material and pure water are mixed at a weight ratio of 1:0.75 to 1:1.5 to form a mixed liquid. In the stirring step S13, the mixed solution is stirred at room temperature to completely dissolve the raw material in pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com