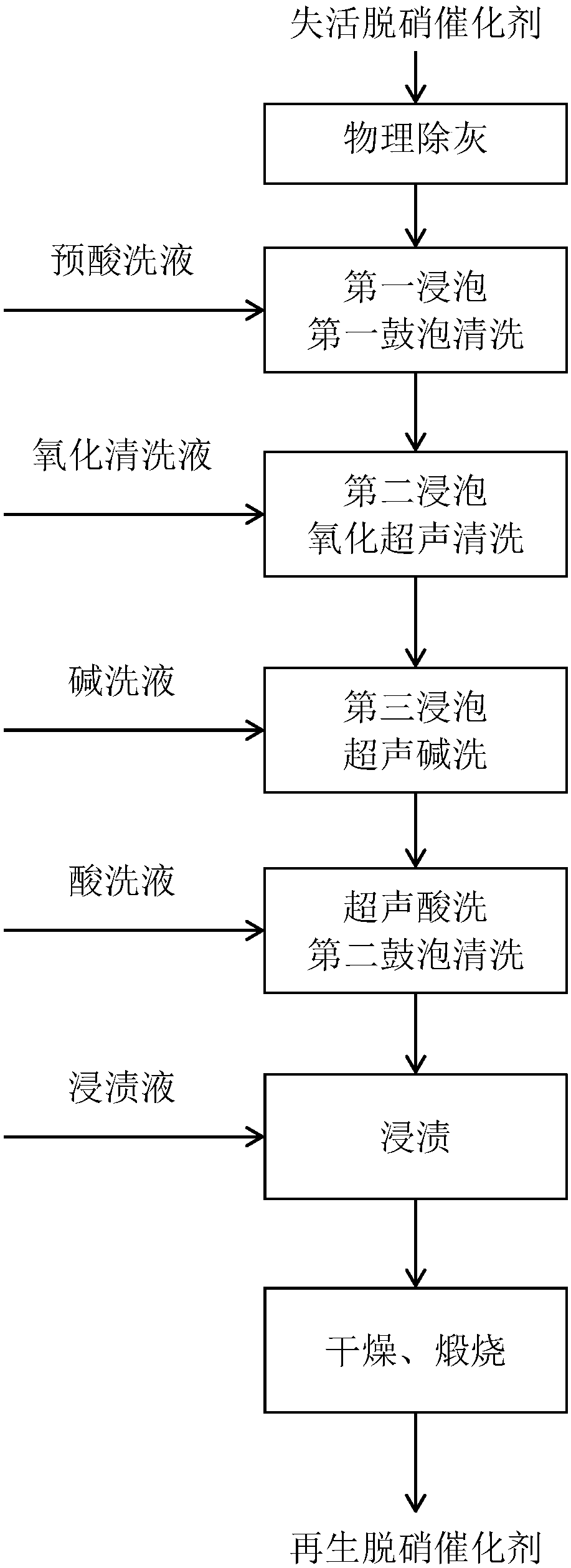

Regeneration method of inactivated denitration catalyst

A denitration catalyst and catalyst technology, which can be used in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as insufficient removal of arsenic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of various catalyst cleaning solutions

[0059] Pre-pickling liquid: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3, the content is respectively 0.3mol / l, 0.2mol / l, 0.025% by weight, 0.05% by weight, 0.08% by weight, pH <3;

[0060] Oxidation cleaning solution: containing 5% by weight of hydrogen peroxide;

[0061] Alkali lotion: containing sodium hydroxide, JFC, OP-10 and defoamer W-3, the contents are respectively 0.3mol / l, 0.025% by weight, 0.05% by weight, 0.08% by weight, pH=12;

[0062] Pickling solution: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3; contents are 0.3mol / l, 0.2mol / l, 0.025% by weight, 0.05% by weight, 0.08% by weight, pH< 3;

[0063] Impregnation solution: containing ammonium metavanadate, ammonium heptamolybdate, and oxalic acid, the content of which is 0.5% by weight, 1% by weight, and 2% by weight, respectively.

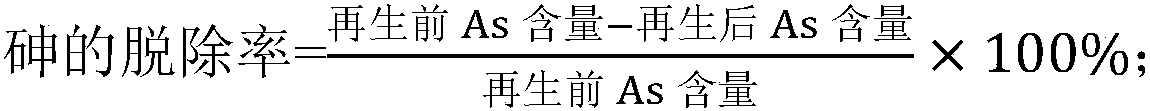

[0064] (2) Regeneration of the deactivated denitration cataly...

Embodiment 2

[0074] (1) Preparation of various catalyst cleaning solutions

[0075] Pre-pickling liquid: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3, the contents are respectively 0.2mol / l, 0.05mol / l, 0.01% by weight, 0.1% by weight, 0.3% by weight, pH <3;

[0076] Oxidation cleaning solution: containing 4% by weight of potassium perchlorate;

[0077] Alkali lotion: containing sodium hydroxide, JFC, OP-10 and defoamer W-3, the contents are respectively 0.5mol / l, 0.03% by weight, 0.3% by weight, 0.15% by weight, pH=14;

[0078] Pickling solution: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3; contents are 0.5mol / l, 0.05mol / l, 0.01% by weight, 0.1% by weight, 0.3% by weight, pH < 3;

[0079] Impregnation solution: containing ammonium tungstate, ammonium molybdate, and ammonia water, the content of which is 2% by weight, 1% by weight, and 5% by weight respectively.

[0080] (2) Regeneration of the deactivated denitration catalyst: the ...

Embodiment 3

[0090](1) Prepare aqueous solutions of various catalyst cleaning solutions

[0091] Pre-pickling liquid: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3, the content is respectively 0.4mol / l, 0.09mol / l, 0.2% by weight, 0.25% by weight, 0.01% by weight, pH <3;

[0092] Oxidation cleaning solution: containing 10% by weight of potassium permanganate;

[0093] Alkaline lotion: containing ammonia, JFC, OP-10 and defoamer W-3, the contents are respectively 0.05mol / l, 0.15% by weight, 0.25% by weight, 0.1% by weight, pH=13;

[0094] Pickling solution: containing sulfuric acid, ammonium sulfate, JFC, OP-10 and defoamer W-3; contents are 0.4mol / l, 0.09mol / l, 0.2% by weight, 0.25% by weight, 0.01% by weight, pH< 3;

[0095] Impregnation solution: containing ammonium metavanadate, ammonium molybdate, cerium nitrate, and oxalic acid, the content of which is 0.5% by weight, 1% by weight, 1% by weight, and 3% by weight respectively.

[0096] (2) Regeneration of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com