Multi-stage screening and impurity removing device for high-purity industrial salt production

An industrial salt, high-purity technology, applied in the fields of filtration and screening, solid separation, chemical instruments and methods, etc., can solve the problems of easy formation of agglomeration of industrial salt, inconvenient screening and discharge, increase of production cost, etc., to reduce the mashing time As well as the effect of labor force, ease of screening and processing, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The invention provides a multi-stage screening impurity removal device for high-purity industrial salt production, including:

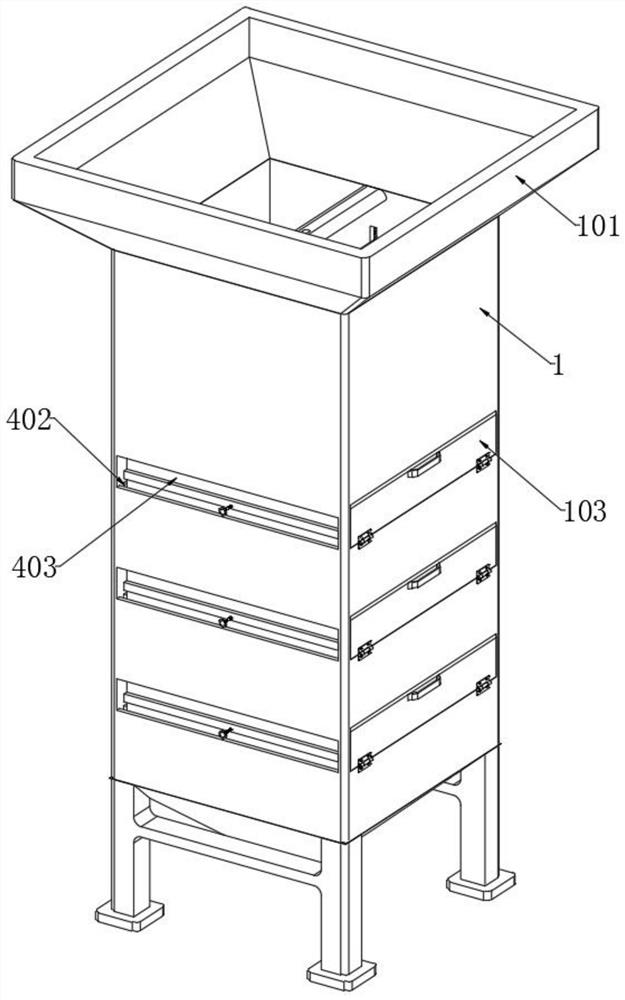

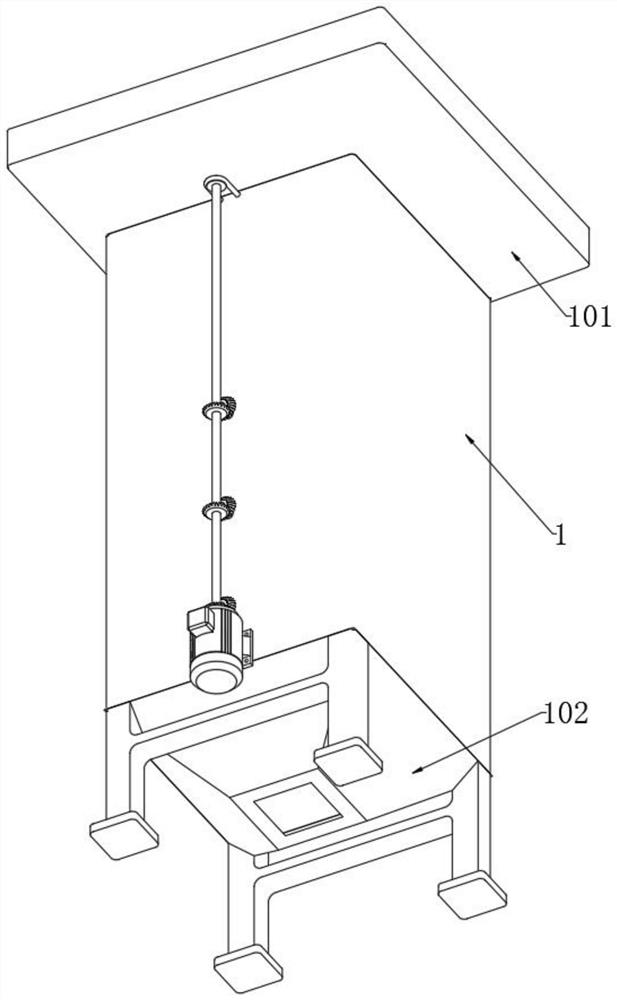

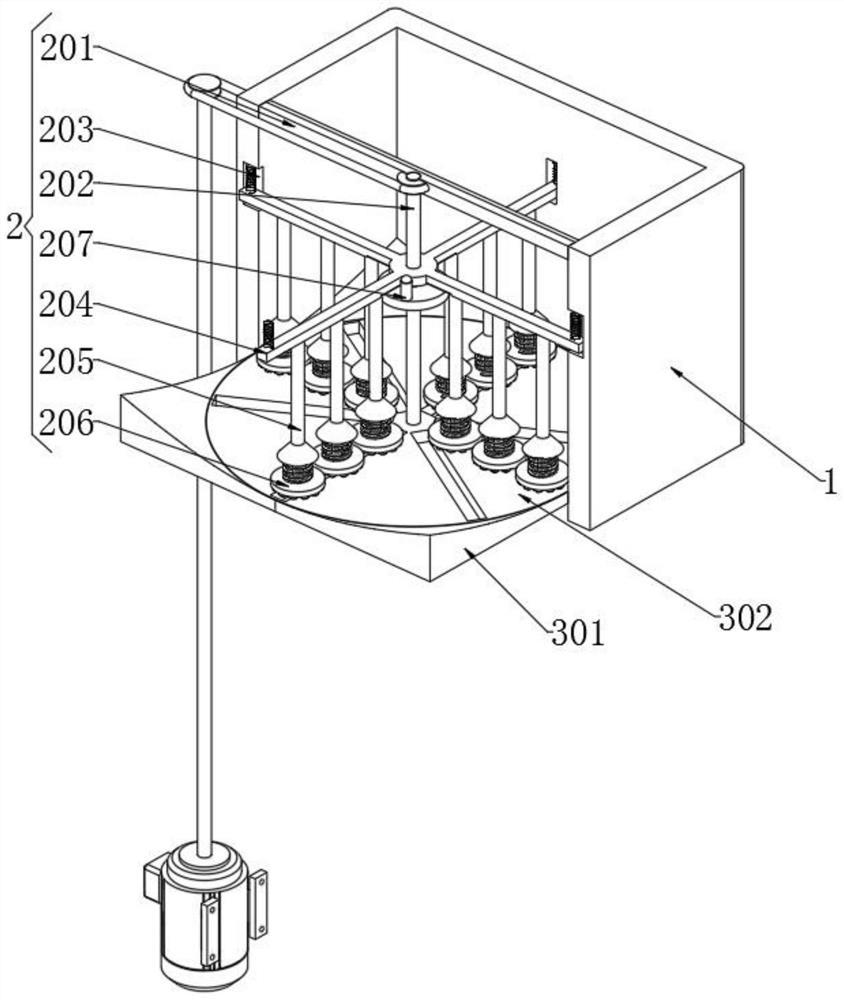

[0036] refer to figure 1 and figure 2, the main body 1, legs are installed at the angle between the bottom edge of the main body 1, and a motor is installed on the side bottom of the main body 1, three bevel gears are installed on the top of the motor, and a crushing mechanism 2 is installed inside the main body 1, the main body 1 Including: deflector 101, a conical deflector 101 is installed on the top of the main body 1, so that the industrial salt is poured inside the main body 1, the deflector 101 is a conical structure, and the deflector 101 is installed on the main body 1 The top of the discharge part 102, the discharge part 102 is a conical structure, and the top of the discharge part 102 is connected to the bottom of the main body 1; the baffle plate 103, the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com