Production process of large-diameter flexible composite pipe

A flexible composite pipe and production process technology, applied in the direction of coating, etc., can solve the problems of difficult-to-form inner lining pipe layer, low strength, easy bending or breaking of pipe blanks, etc., and achieve the effect of widening the scope of application and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

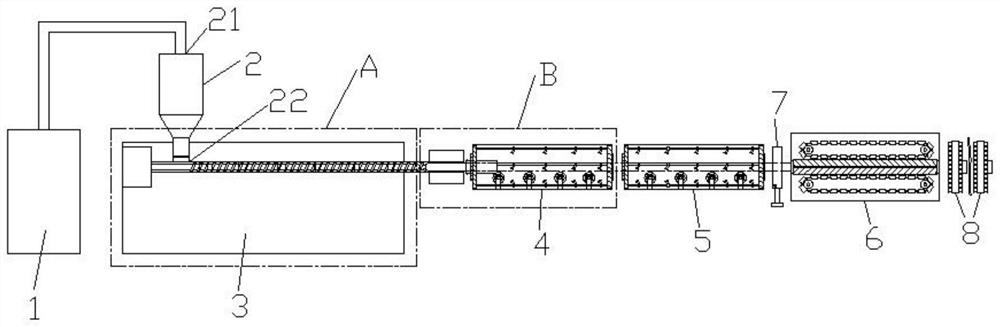

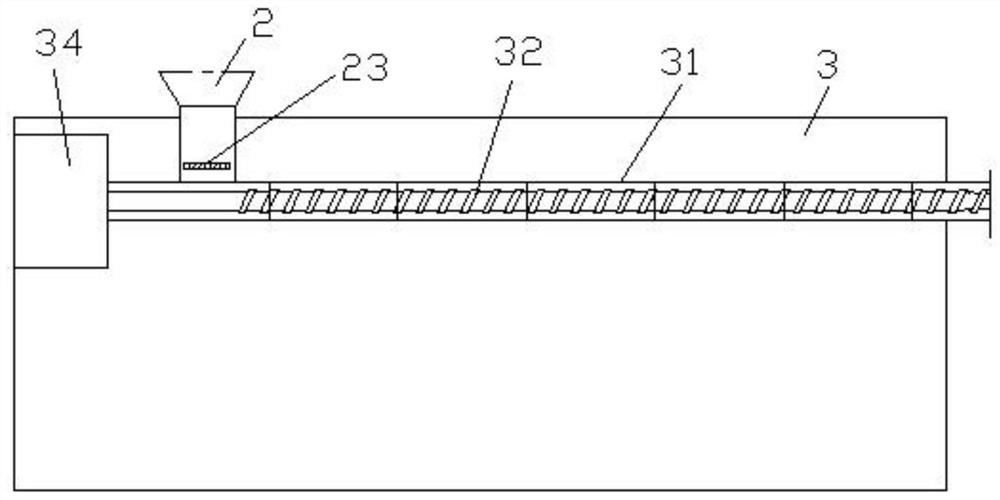

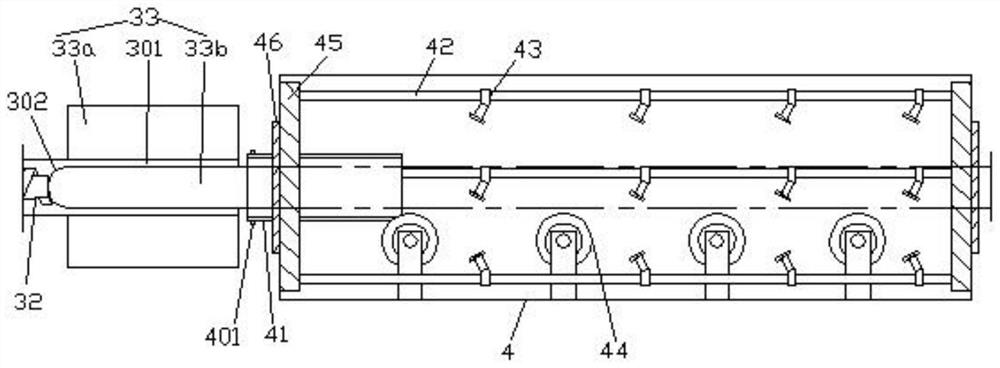

[0030] Refer to attached Figure 1-10 The production process of a large-diameter flexible composite pipe shown includes the following equipment in sequence: a suction machine 1, which is used to absorb and transport the pipe-making raw material (preferably granular polyethylene) to the storage cylinder at a rated capacity and speed 2; material storage tank 2 (with feed port 21 and material discharge port 22), the raw material transported by the suction machine 1 is entered from the feed port 21 for storage, and at the same time the rated capacity and speed (at the bottom of the storage tank 2) The plug-in regulating plate 23) is transported to the screw extruder 3 through the discharge port 22; the screw extruder 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com