Device and method for monitoring pultrusion process parameters of composite material in real time

A technology of pultrusion molding and process parameters, which is applied in the field of real-time monitoring devices for composite material pultrusion molding process parameters, can solve problems such as high cost, process parameters are susceptible to external interference, and cannot accurately reflect the solidification state of composite materials Small, easy to control and the effect of subsequent process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a device for real-time monitoring of composite material pultrusion process parameters;

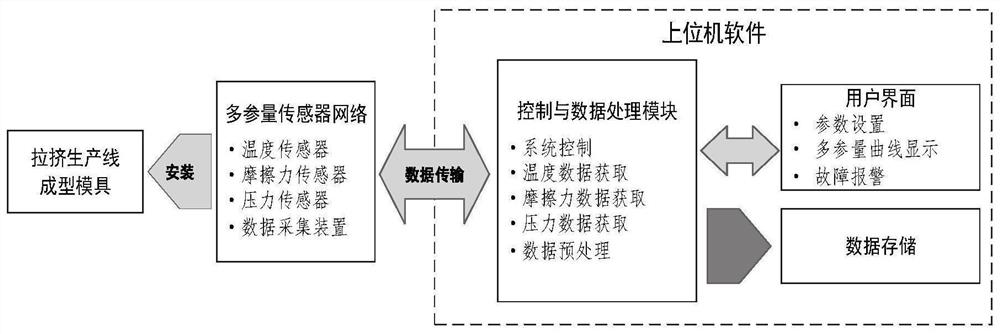

[0037] Such as figure 1 As shown, a real-time monitoring device for composite material pultrusion process parameters, including:

[0038] The upper computer, the upper computer is connected with the temperature sensor, the friction sensor and the pressure sensor respectively; the upper computer is configured as:

[0039] Obtain the temperature data inside the mold through the temperature sensor installed on the mold;

[0040] Obtain the friction data inside the mold through the friction sensor installed on the mold;

[0041] Obtain the pressure data inside the mold through the pressure sensor set on the mold;

[0042] The host computer performs preprocessing on temperature data, friction data and pressure data, and performs curve representation and fault alarm on the three data.

[0043] Further, the temperature sensor includes: a thermal resistor, the f...

Embodiment approach

[0071] (1) Temperature detection

[0072] This embodiment adopts the resistance temperature measurement method, uses PT100 as the temperature sensitive element, converts the temperature information into the change of the resistance value, and then converts the resistance value into a voltage value through a precision conversion circuit, and finally realizes the temperature value through the analog-to-digital conversion. Digitizing. PT100 temperature sensor is a resistance temperature detector made of platinum (Pt), which belongs to positive resistivity. Its resistance value will change with the change of temperature, and there is a certain relationship between its output signal and temperature variable. The continuous function relationship, as long as the resistance value of PT100 is obtained, the current temperature value can be calculated.

[0073] A three-wire resistance-voltage conversion circuit is used, and the schematic diagram is attached Figure 5 Shown, where Rpt10...

Embodiment 2

[0090] This embodiment provides a method for real-time monitoring of composite material pultrusion process parameters;

[0091] A method for real-time monitoring of composite material pultrusion process parameters, comprising:

[0092] Set the temperature sensor inside the mold by drilling and installing to obtain the temperature data inside the mold;

[0093] Obtain the friction data inside the mold through the friction sensor installed on the mold;

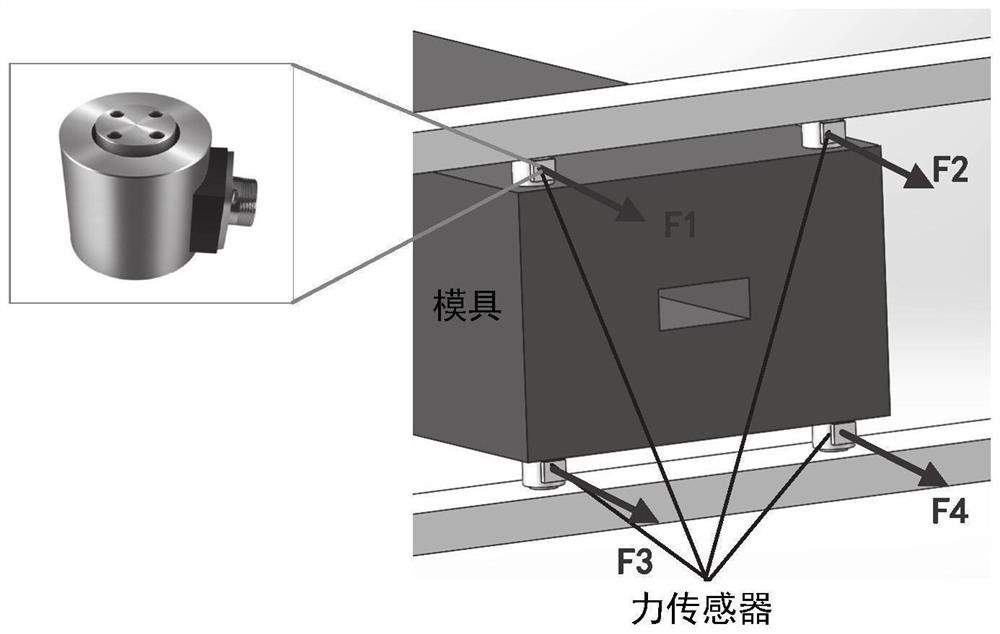

[0094] Obtain the pressure data inside the mold through the pressure sensor set at the position of the mold fixing screw;

[0095] The host computer performs preprocessing on temperature data, friction data and pressure data, and performs curve representation and fault alarm on the three data.

[0096] Further, the temperature sensor installed inside the mold by means of punching holes to obtain temperature data inside the mold; specifically includes:

[0097] The resistance value of PT100 increases at a constant speed as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com