Preparation method of magnesium-doped cobalt liquid and nickel-cobalt-manganese ternary precursor

A nickel-cobalt-manganese and precursor technology, applied in chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problems of increasing production costs, increasing the types of ingredients, and achieving the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

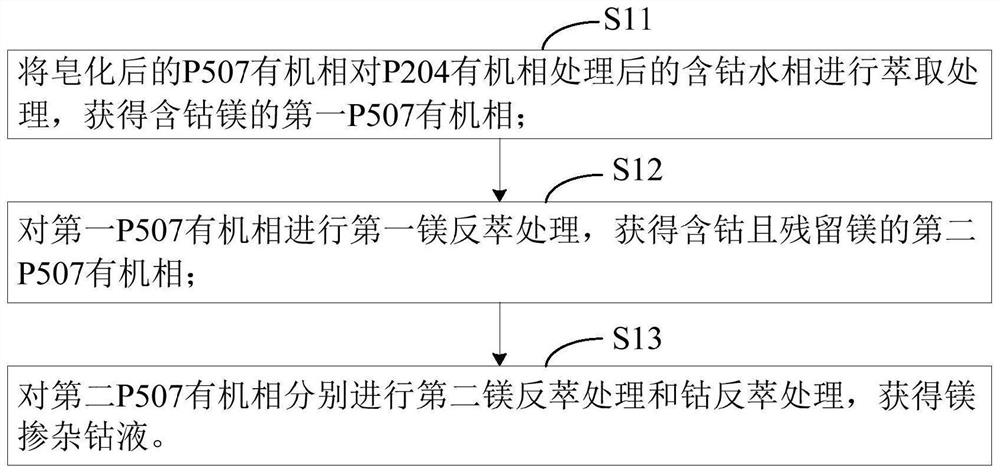

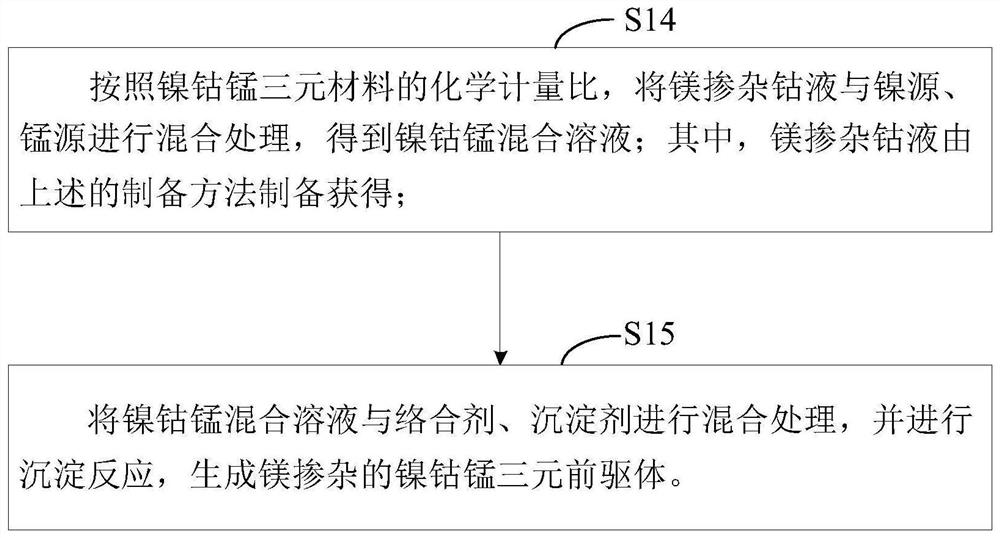

[0030] The first aspect of the embodiment of the present application provides a method for preparing a magnesium-doped cobalt liquid, the preparation method comprising:

[0031] S11: extracting the cobalt-containing aqueous phase after the P507 organic phase has been treated with the P204 organic phase to obtain the first P507 organic phase containing cobalt and magnesium;

[0032] S12: performing a first magnesium back-extraction treatment on the first P507 organic phase to obtain a second P507 organic phase containing cobalt and residual magnesium;

[0033] S13: performing the second magnesium back-extraction treatment and cobalt back-extraction treatment on the second P507 organic phase, respectively, to obtain a magnesium-doped cobalt liquid.

[0034] The preparation method of the magnesium-doped cobalt solution provided in the examples of the present application first uses the P507 organic phase to extract the cobalt-containing aqueous phase after the P204 organic phase t...

Embodiment 1

[0060] This embodiment provides a method for preparing a magnesium-doped cobalt solution and a magnesium-doped nickel-cobalt-manganese ternary precursor.

[0061] The preparation method of magnesium-doped cobalt liquid comprises the following steps:

[0062] S11 (saponification): Continuously add NaOH solution with a concentration of 11mol / L at a flow rate of 600-1200L / h and continuously add P507 extractant (2-ethylhexyl phosphate mono-2-ethylhexyl ester at a flow rate of 8000-15000L / h ) carry out saponification reaction, obtain the P507 organic phase after saponification, and its saponification rate is controlled at 40-60%;

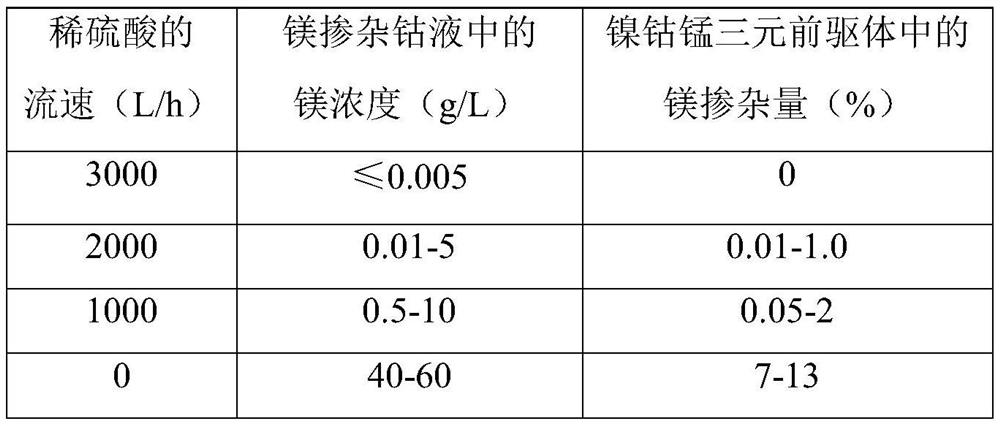

[0063] S12 (extraction): at a flow rate of 2000-8000L / h, the cobalt-containing aqueous phase after the treatment of the P204 organic phase with a magnesium content of 5-20g / L and a cobalt content of 50-80g / L is added to the saponified P507 organic phase Carry out extraction treatment in, obtain the first P507 organic phase containing cobalt and magnesiu...

Embodiment 2

[0070] This embodiment provides a method for preparing a magnesium-doped cobalt solution and a magnesium-doped nickel-cobalt-manganese ternary precursor.

[0071] The preparation method of magnesium-doped cobalt liquid comprises the following steps:

[0072] S11 (saponification): Continuously add NaOH solution with a concentration of 11mol / L at a flow rate of 600-1200L / h and continuously add P507 extractant (2-ethylhexyl phosphate mono-2-ethylhexyl ester at a flow rate of 8000-15000L / h ) carry out saponification reaction, obtain the P507 organic phase after saponification, and its saponification rate is controlled at 40-60%;

[0073] S12 (extraction): at a flow rate of 2000-8000L / h, the cobalt-containing aqueous phase after the treatment of the P204 organic phase with a magnesium content of 5-20g / L and a cobalt content of 50-80g / L is added to the saponified P507 organic phase Carry out extraction treatment in, obtain the first P507 organic phase containing cobalt and magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com