A kind of amphiphilic siloxane gel and preparation method thereof

A kind of technology of siloxane gel, cyclic siloxane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides an amphiphilic siloxane gel, the preparation method of which is as follows:

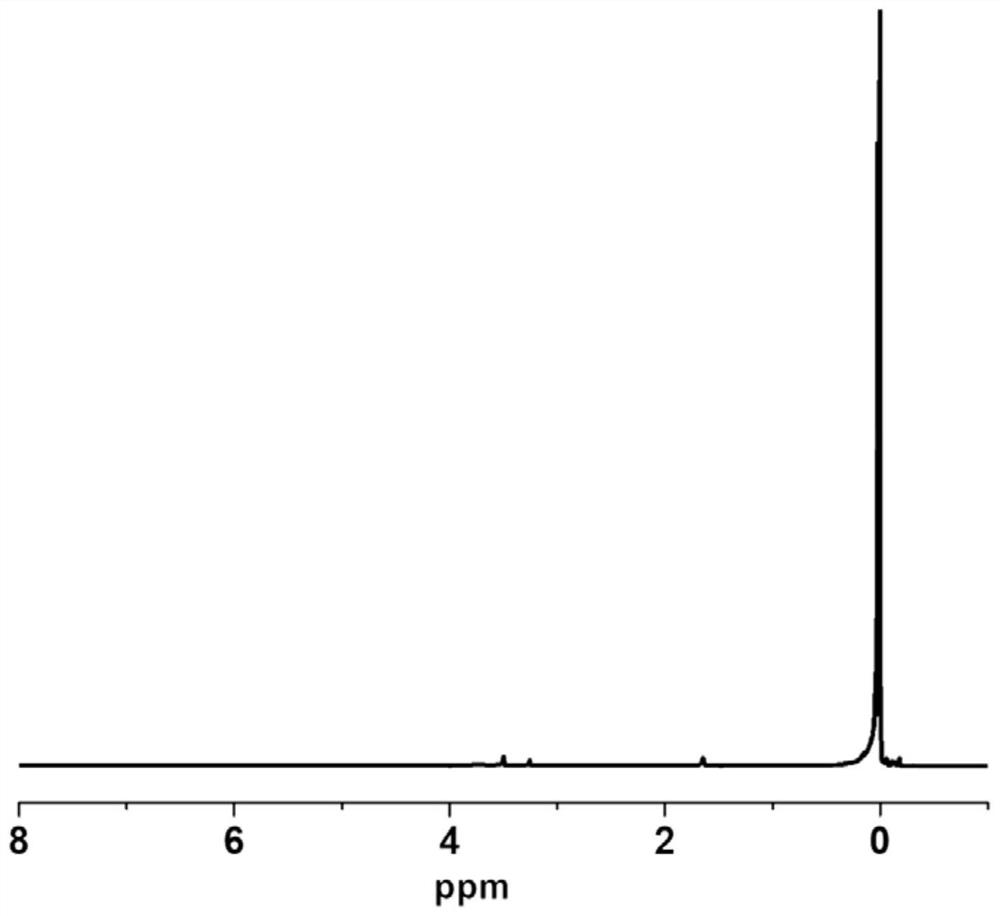

[0043] (1) Take 10g of octamethylcyclotetraoxosilane, add 0.5g of tetramethylammonium silanol, stir and mix evenly at 80°C, then place it in a nitrogen atmosphere at 85°C for 12 hours, and place it in an open environment at room temperature after the reaction is completed In , after cooling to room temperature, the gel substrate can be obtained, and its NMR image is as follows figure 1 Shown, at 0ppm place, the peak of obvious linking methyl group with silicon appears, and at 3.25ppm place, the peak of obvious linking methyl group with nitrogen appears;

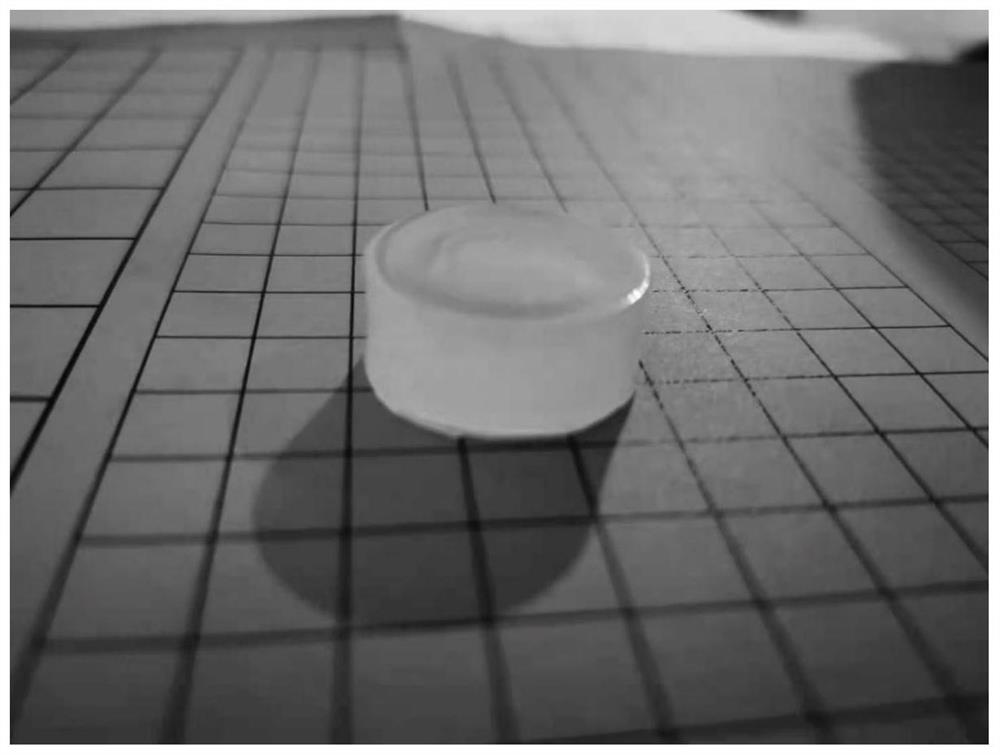

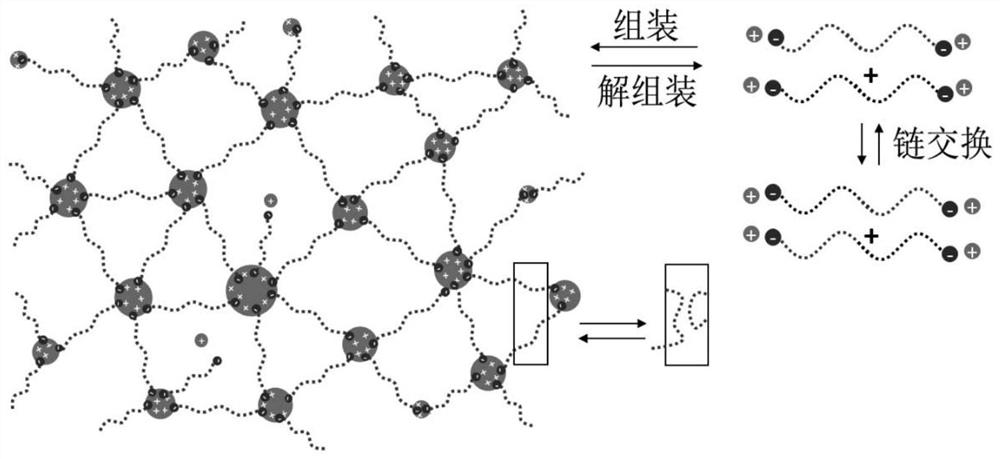

[0044] (2) Soak the obtained gel base material in 50cst simethicone oil to balance to obtain amphiphilic silicone gel. The physical picture of the material is as follows figure 2 As shown, it can be seen that it is a translucent elastomer, and its structure is as follows image 3 As shown, it is a dynamic network. ...

Embodiment 2

[0046] This embodiment provides an amphiphilic siloxane gel, the preparation method of which is as follows:

[0047] (1) Take 20g of decamethylcyclopentasiloxane, add 0.5g of tetrabutylphosphine hydroxide, stir and mix evenly at 60°C, then place it in a nitrogen atmosphere at 100°C for 12 hours, and place it in an open environment at room temperature after the reaction is completed , the gel substrate can be obtained after cooling to room temperature;

[0048] (2) Soak the obtained gel substrate into 20 cst of simethicone oil to balance to obtain amphiphilic silicone gel.

Embodiment 3

[0050] This embodiment provides an amphiphilic siloxane gel, the preparation method of which is as follows:

[0051] (1) Take 30g of dodecamethylcyclohexasiloxane, add 0.5g of tetrabutylammonium hydroxide, stir and mix evenly at 90°C, then place it in a nitrogen atmosphere at 60°C for 20h, and place it in an open environment at room temperature after the reaction is completed In, after cooling to room temperature, the gel substrate is obtained;

[0052] (2) Soak the obtained active gel base material in 1000cst of simethicone oil to balance to obtain the amphiphilic silicone gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com