3D printed public chair and manufacturing method thereof

A technology of 3D printing and public seating, which can be applied to vertically adjustable chairs, chairs, and other seating furniture. Economic benefit and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

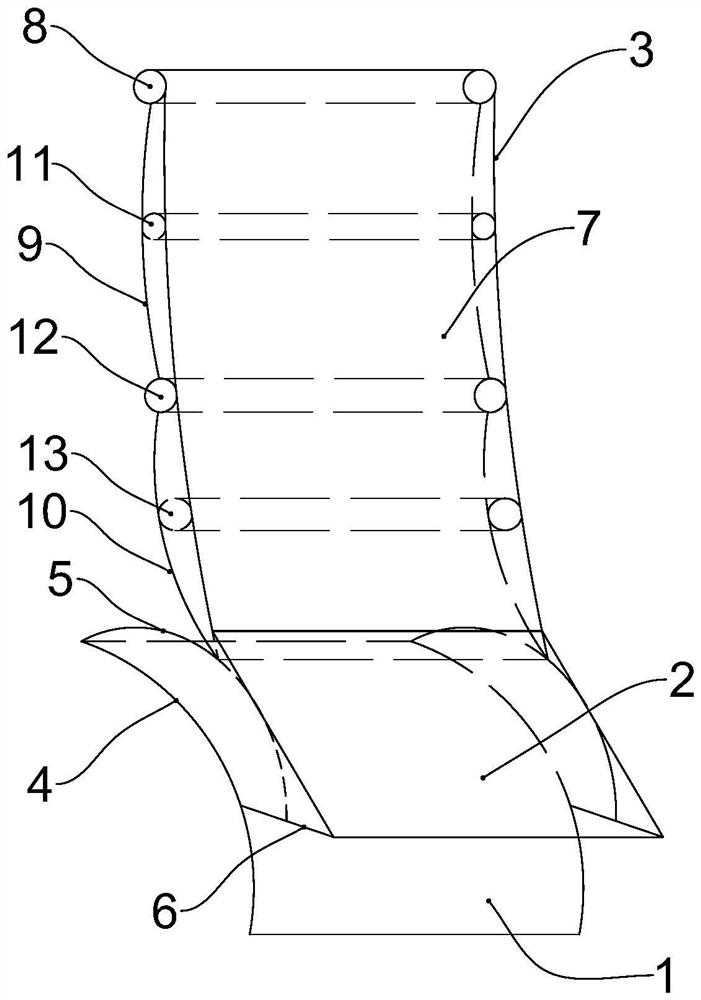

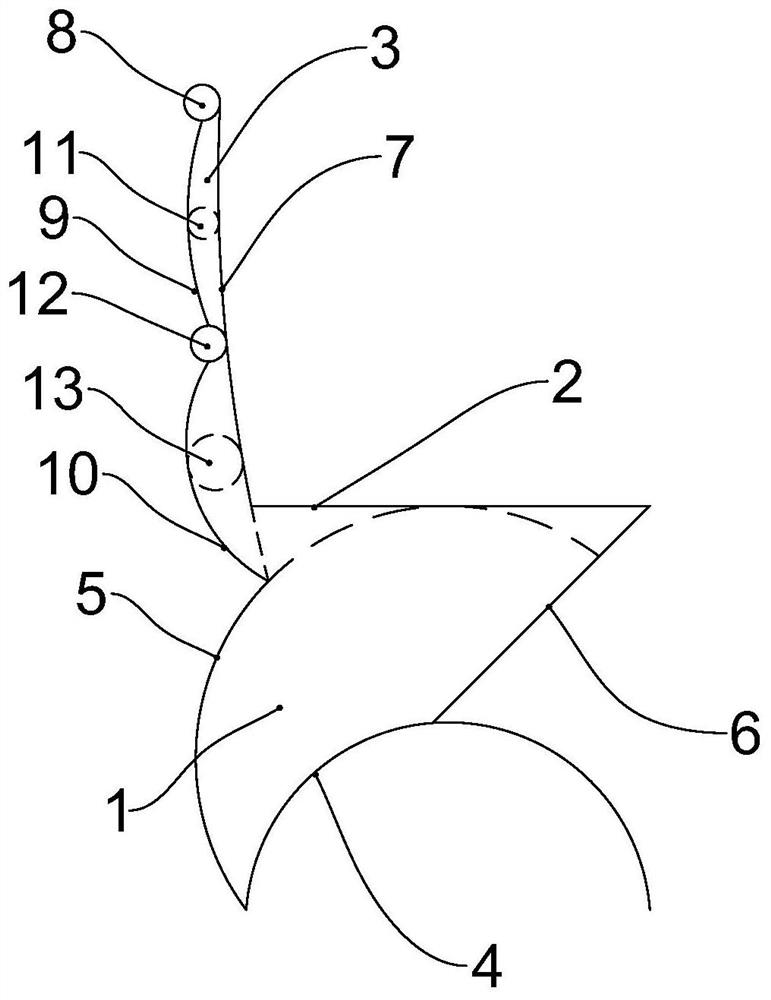

[0036] like figure 1 As shown, the 3D printing public seat of this embodiment includes chair legs 1, a seat seat 2, and a backrest 3. , the chair legs 1 are connected, and the chair legs 1, the chair seat 2 and the backrest 3 are integrally formed by printing layer by layer with a 3D printer; specifically, the bottom surface of the chair leg 1 is a semicircular surface 4 , the front end of the seat 2 and the apex of the semicircular surface 4 are connected to form a diagonal support surface 6, and the bottom edge of the backrest 3 and the rear end of the semicircular surface 4 form an arc surface 5 , the space between the semicircular surface 4, the arc surface 5, and the diagonal bracing surface 6 and the seat 2 is formed as a solid body by 3D printing materials. The semicircular surface 4, the curved surface 5, and the inclined bracing surface 6 design the chair legs in an arched shape, which effectively takes advantage of the high compressive strength of the arched structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com