Spinning forming method for complex thin-wall variable-cross-section component of aluminum alloy splice plate

A spinning forming, aluminum alloy technology, applied in the field of spinning forming of complex thin-walled variable-section components, can solve the problems of low precision, inability to form large or ultra-large thin-walled variable-section components, uneven material properties, etc. The effect of not sticking to the mold, improving the accuracy of the profile, and improving the quality of the spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

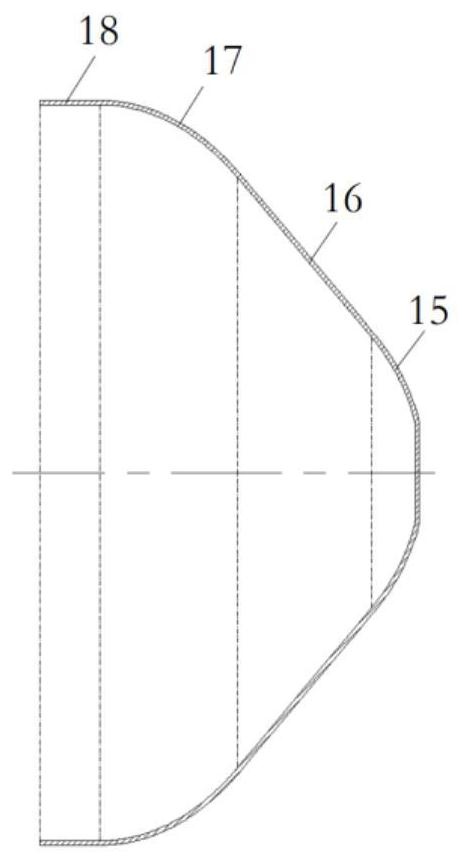

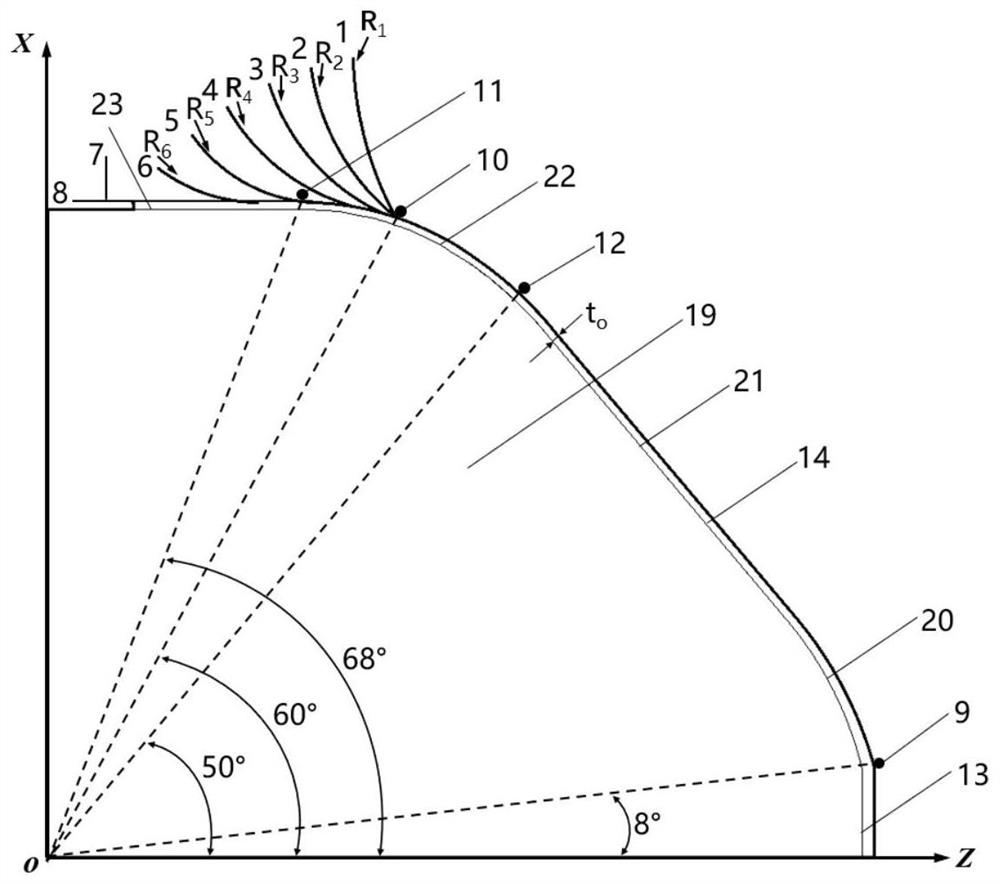

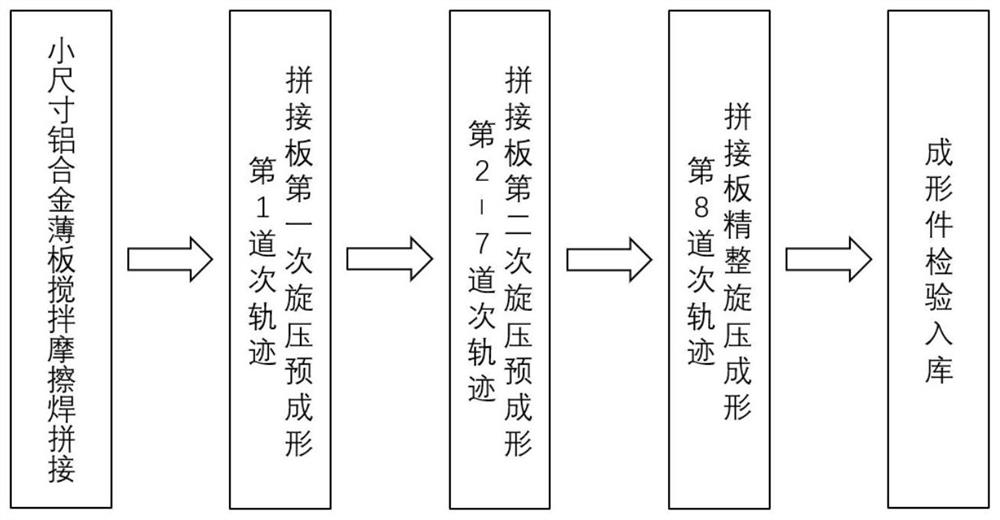

[0059] This embodiment is a track and forming method for the spinning of complex thin-walled variable-section components used for aluminum alloy splicing plates. The flow charts of the spinning track design and the forming method are as follows figure 2 and image 3 shown.

[0060] The complex thin-wall variable-section member is a hollow body of revolution; the rear end face is a plane, and the front end face to the middle is a variable cross-section, which sequentially forms the component spherical segment 15, component cone segment 16 and component ellipsoid in the aluminum alloy splicing plate paragraph 17. The middle part to the back section of the complex thin-wall variable-section member is an equal-diameter section, forming a straight section 18 of the member.

[0061] The aluminum alloy splicing plate is formed by friction stir welding of small-sized aluminum alloy thin plates.

[0062] The outline surface of the spinning mandrel is divided into spinning mandrel sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com