Pressing device for upper cover plate of radiator shell for 5G base station

A technology of a pressing device and a radiator, applied in the field of pressing devices, can solve the problems of long waiting time and low pressing efficiency, and achieve the effects of improving efficiency, reducing cooling time and increasing cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

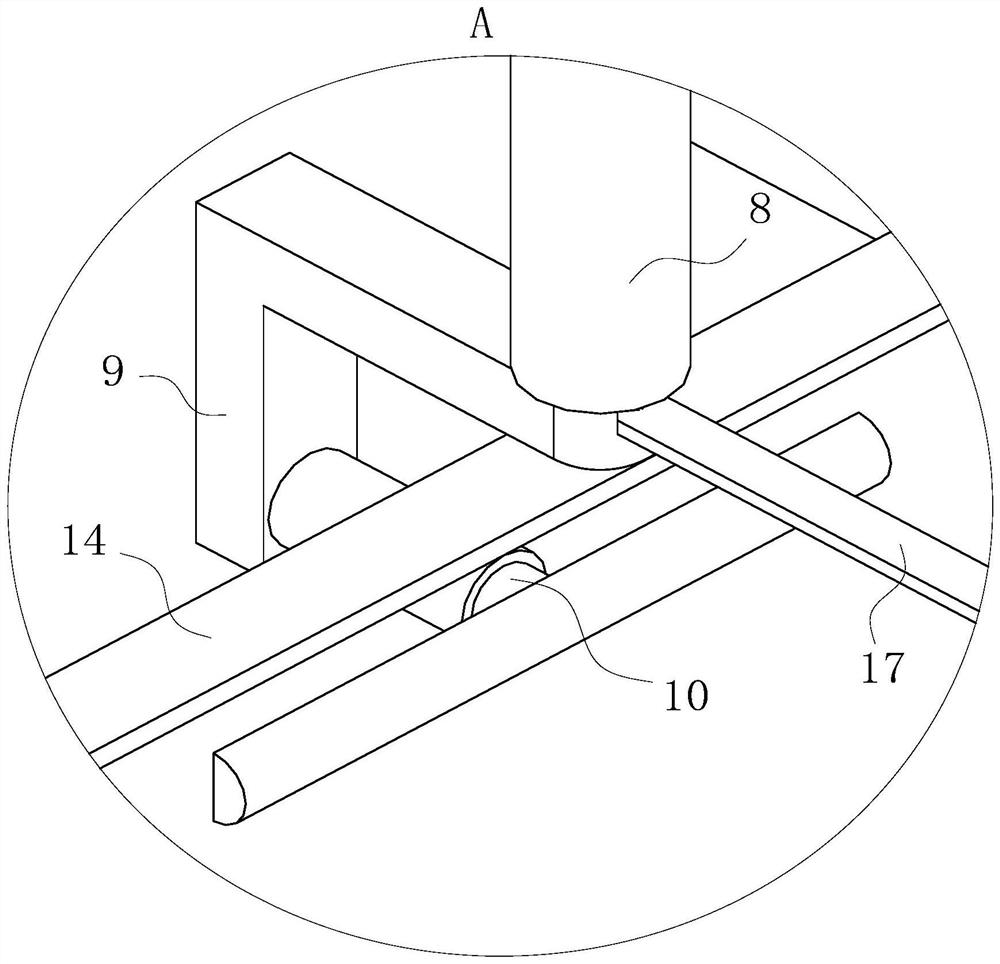

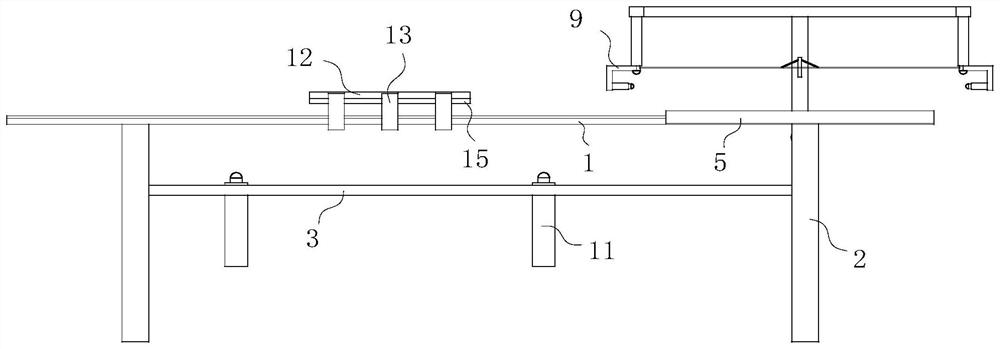

[0034] As a specific embodiment of the present invention, the push plate 14 is a semi-cylindrical strip, and the surface of the push plate 14 is polished; The contact position of the cover plate is always changing to prevent the serious wear of the push plate 14. After the surface of the push plate 14 is polished, the friction force between the push plate 14 and the upper cover plate is less, which reduces the wear of the upper cover plate.

[0035] The working principle of the present invention:

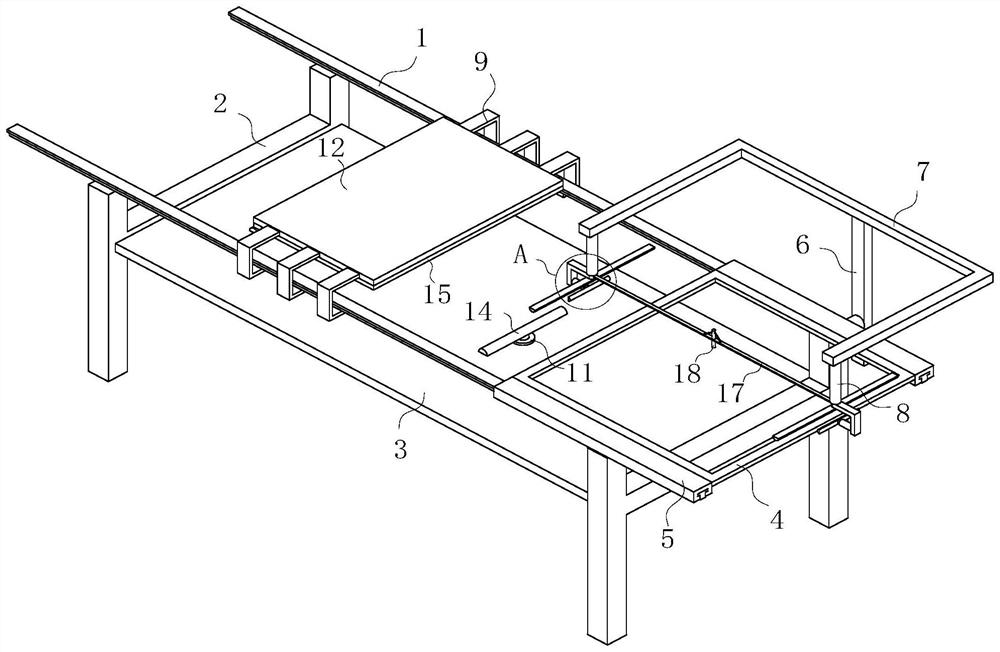

[0036] Refer to the attached Figure 1-5 , because the pressing device of the existing upper cover plate needs to wrap a part of the upper cover plate at the edge of the shell when pressing, because the shell and the upper cover plate have just been processed, there is more heat, and the shell needs to be fixed , followed by pressing in multiple directions to press the upper cover and the outer shell, and it is necessary to wait for the outer shell and the upper cover to cool down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com