Quantitative filling system and filling method thereof

A technology of filling system and mass flow meter, which is applied in the field of automatic packaging, can solve the problems of deviation, uncontrollability, and deviation of packaging material weight, etc., to achieve high filling accuracy, avoid hygienic dead ends, and improve The effect of filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

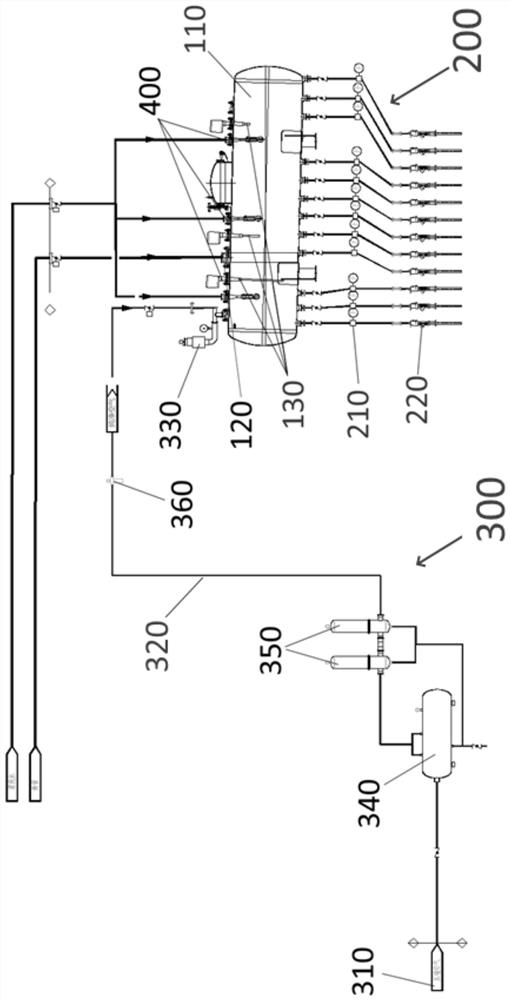

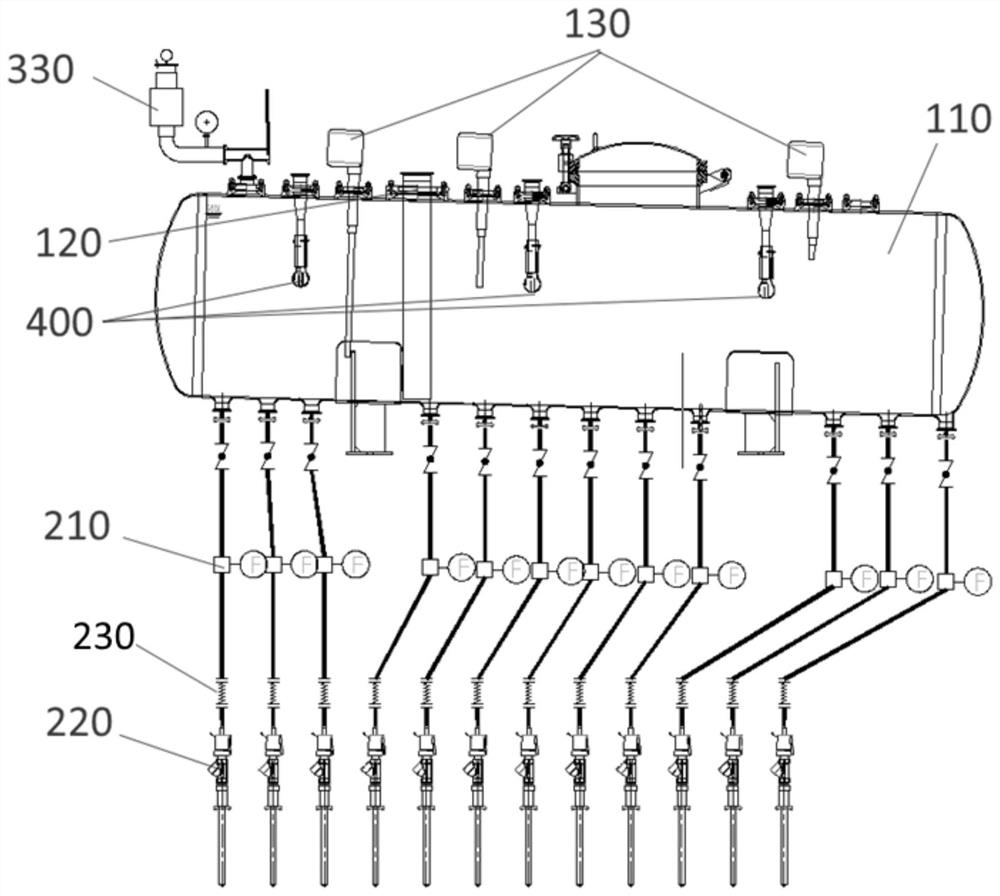

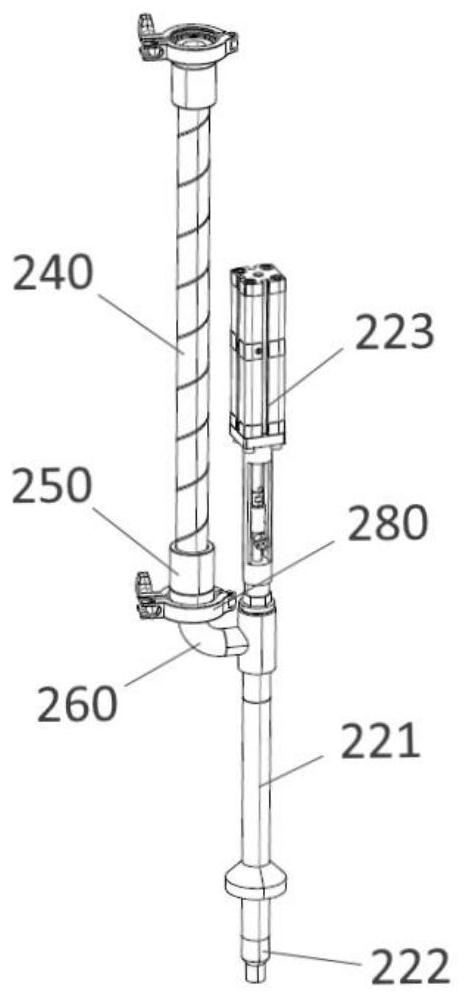

[0042] See attached Figures 1 to 2 , a quantitative filling system and filling method thereof, comprising: a material box 110, a feeding assembly 200, a pressure assembly 300 and an automatic cleaning system.

[0043] The material box 110 is a closed cavity. In this embodiment, the material box 110 is a capsule-type sealed material box 110, and the material box 110 is customized as a pressure vessel material box 110 that can carry a pressure of 3kg, which is suitable for Fill the feed liquid. Of course, for those skilled in the art, the material box 110 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com