Sulfate-erosion-resistant concrete as well as proportioning optimization method and application thereof

A technology of concrete and sulfate, which is applied in earthwork drilling, material analysis using wave/particle radiation, wellbore lining, etc. It can solve the problems of complex batching and process, high transportation cost, poor application, etc., and is beneficial to engineering application , save engineering cost, and maintain the effect of long-term performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

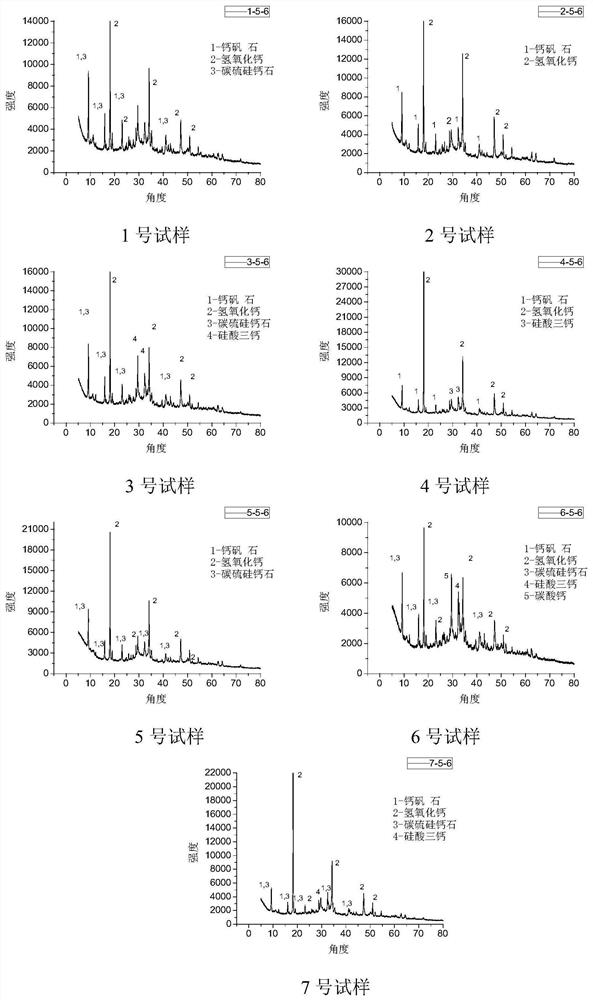

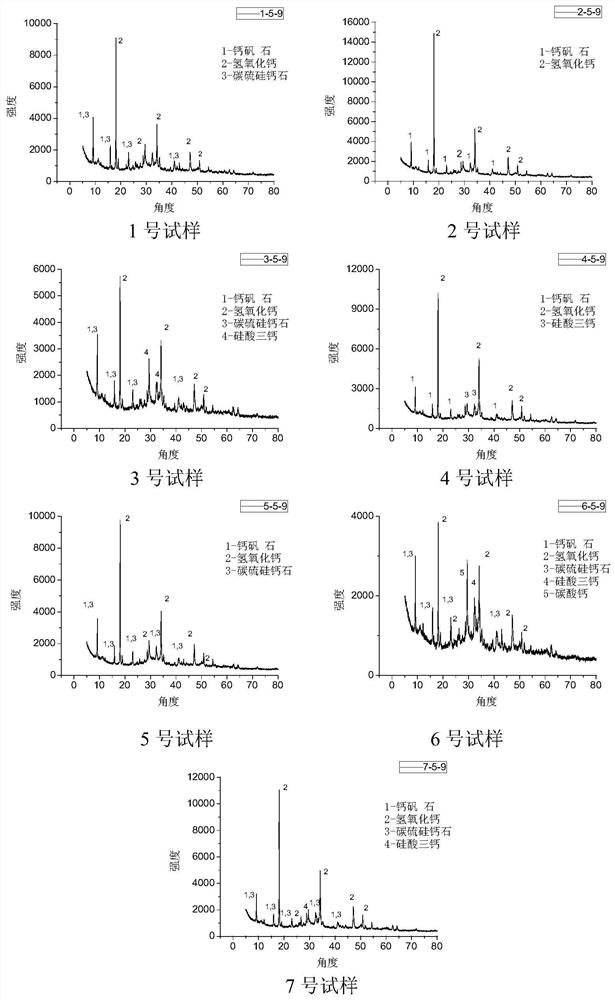

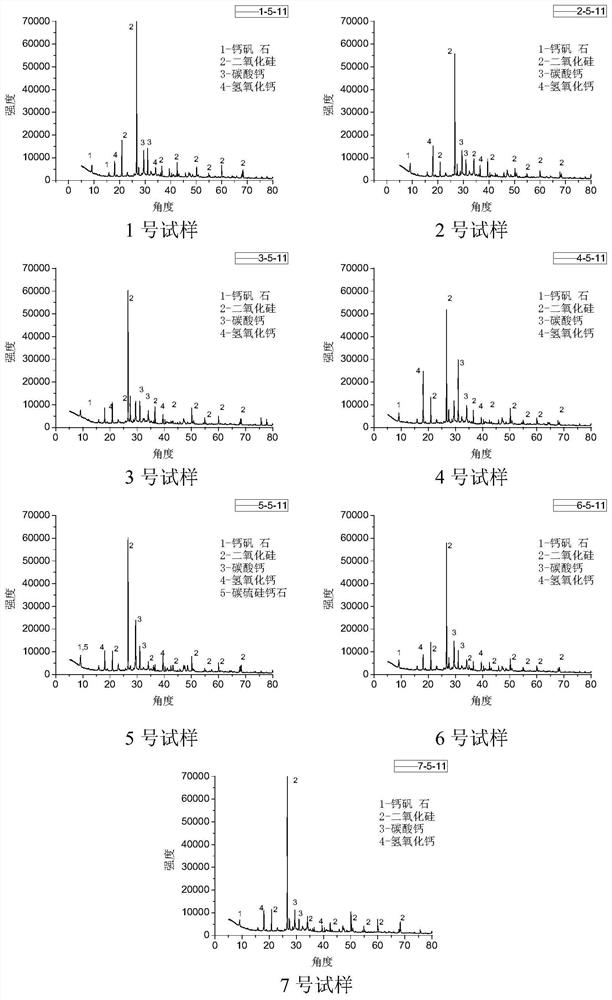

[0084] Embodiment 1: In this embodiment, the TSA failure process of Dugongling Tunnel is taken as an example, and this experiment is set up according to the corrosive environment where sulfate-type corrosion occurs in the primary concrete of Dugongling Tunnel.

[0085] The engineering geological conditions of Dugongling Tunnel are weakly permeable limestone and gypsum rock formations. The TSA failure is affected by groundwater and destroys the gel properties of cement in concrete. Considering the geological conditions and water permeability, the existing concrete ratio is adjusted. Water-binder ratio, so as to realize the comparative anti-corrosion test with the existing concrete ratio.

[0086] 1. According to the failure characteristics of TSA, two kinds of cement and two kinds of stones were selected for the test to design the mix ratio. The cements are: P.O42.5 and P.I42.5, and the stones are limestone and basalt, and the outside world is fully considered The influence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com