Small molecule migration-resistant, low-smoke flame-retardant and ablation-resistant thermal insulation material and preparation method thereof

A technology of thermal insulation material and ablation resistance, which is applied in the field of ablation resistance materials and can solve the problems of complex regulation process of ablation resistance, poor resistance to small molecule migration, and poor flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

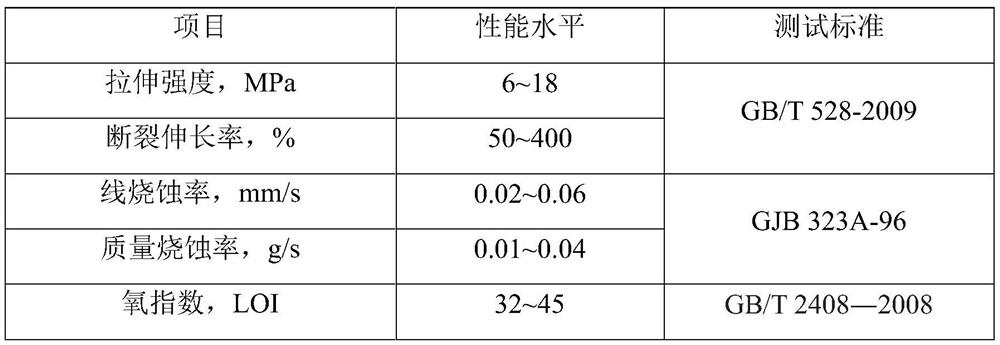

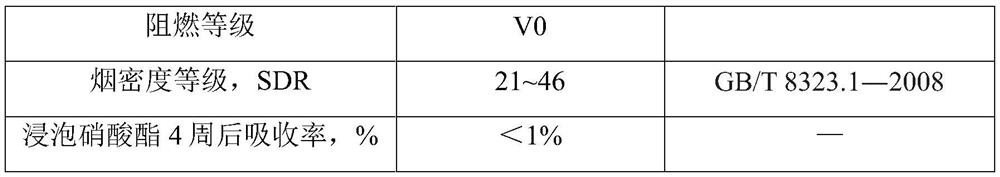

specific Embodiment 1

[0026] Specific example 1: polyphosphazene elastomer (substituent is aryloxy group), 100 parts; magnesium oxide, 1 part; zinc oxide, 3 parts; silicon dioxide, 30 parts; dicumyl peroxide, 1.5 parts. The thermal insulation material prepared by formula components has a tensile strength of 8.4MPa, an elongation at break of 328%, a linear ablation rate of 0.067mm / s, a mass ablation rate of 0.048g / s, and an oxygen index LOI value of 33 , flame retardant grade V0 grade, smoke density grade SDR is 28.9, absorption rate is 0.72% after soaking in nitrate ester for 4 weeks. Moreover, the vulcanization performance of the material is excellent, and the mixing process performance is excellent.

specific Embodiment 2

[0027] Specific embodiment 2: polyphosphazene elastomer (substituting group is aryloxy group), 100 parts; Magnesium oxide, 1 part; Zinc oxide 3 parts; Quartz fiber, 3 parts; Aramid fiber chopped, 5 parts; , 30 parts, phenolic resin, 5 parts, aluminum oxide powder, 15 parts; dicumyl peroxide, 1.5 parts. The thermal insulation material prepared by formula components has a tensile strength of 10.2MPa, an elongation at break of 125%, a linear ablation rate of 0.036mm / s, a mass ablation rate of 0.028g / s, and an oxygen index LOI value of 35 , Flame retardant grade V0, smoke density grade SDR 23.1, absorption rate 0.55% after soaking in nitrate ester for 4 weeks. Moreover, the vulcanization performance of the material is excellent, and the mixing process performance is excellent.

specific Embodiment 3

[0028] Specific embodiment 3: polyphosphazene elastomer (substituting group is aryloxy group), 100 parts; Magnesium oxide, 1 part; Zinc oxide 3 parts; Carbon fiber, 3 parts; Polyimide pulp, 5 parts; Carbon black , 30 parts, phenolic resin, 5 parts, aluminum oxide powder, 15 parts; dicumyl peroxide, 1.5 parts. The thermal insulation material prepared from the formula components has a tensile strength of 8.2MPa, an elongation at break of 172%, a linear ablation rate of 0.045mm / s, a mass ablation rate of 0.037g / s, and an oxygen index LOI value of 34 , Flame retardant grade V0, smoke density grade SDR is 20.8, absorption rate is 0.52% after soaking in nitrate ester for 4 weeks. Moreover, the vulcanization performance of the material is excellent, and the mixing process performance is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com