Double-layer microencapsulated red phosphorus flame retardant containing cyclodextrin as well as preparation method and application of double-layer microencapsulated red phosphorus flame retardant

A technology of microencapsulated red phosphorus and cyclodextrin, which is applied in the flame retardant field of polymer materials, can solve the problems of further improvement of flame retardant effect, weak char formation performance, and weak interaction, so as to improve interfacial compatibility, The effect of reducing impact and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

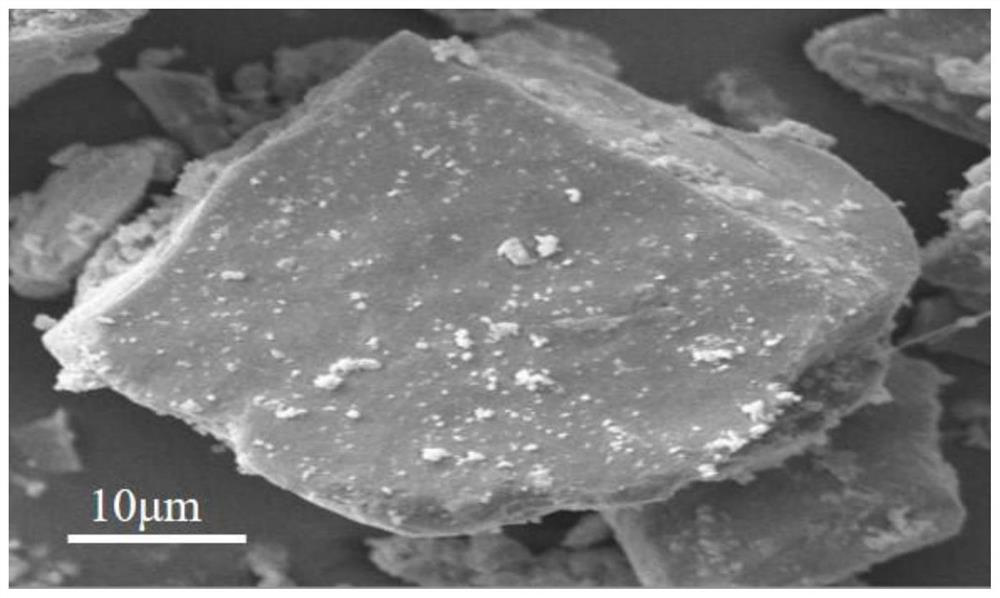

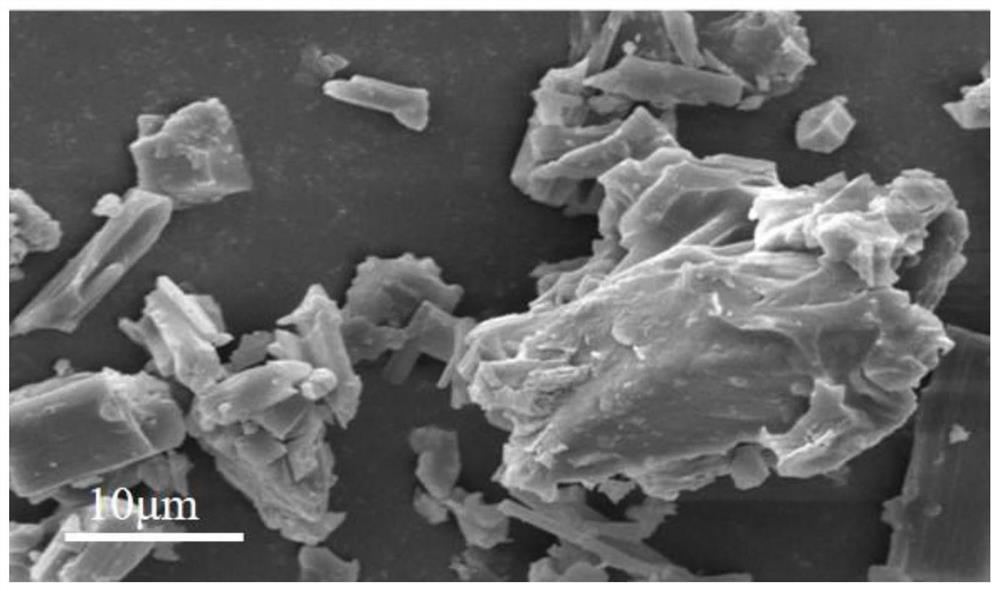

[0039] Add 20g of red phosphorus, 3.2g of melamine, 1.6g of boric acid, and 0.16g of sodium hexametaphosphate into 150ml of water, stir evenly at 80°C and react for 4 hours at a stirring rate of 300r / min. Then lower the temperature to 40° C., the melamine borate is precipitated, and continue to stir for 3 hours, so that the melamine borate is evenly precipitated on the surface of the red phosphorus, and the stirring rate is 500 r / min. Then vacuum filter, dry and grind to obtain melamine borate microcapsule red phosphorus.

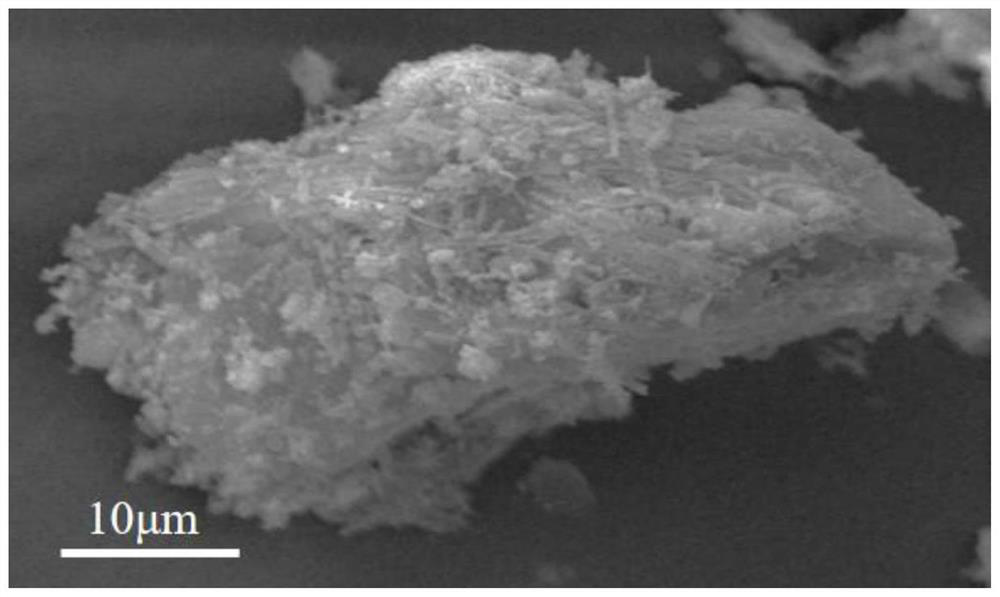

[0040]Dissolve 5 g of β-cyclodextrin in 50 ml of pyridine and stir at 75°C for 60 minutes to completely dissolve it. Add 20 g of melamine borate microcapsule red phosphorus into 150 ml of pyridine, and stir at 75° C. for 60 minutes to make it uniformly dispersed in the solution. The above two solutions were mixed and stirred for another hour, and then 0.03 mol of toluene diisocyanate (TDI, also a trimer of toluene diisocyanate) was added dropwise to the mi...

Embodiment 2

[0042] Add 20g of red phosphorus, 3.2g of melamine, 1.6g of boric acid, and 0.16g of OP-10 into 150ml of water, stir evenly at 80°C and react for 4 hours at a stirring rate of 400r / min. Then lower the temperature to 40° C., the melamine borate is precipitated, and continue to stir for 3 hours, so that the melamine borate is evenly precipitated on the surface of the red phosphorus, and the stirring rate is 500 r / min. Then vacuum filter, dry and grind to obtain melamine borate microcapsule red phosphorus.

[0043] Dissolve 5g of β-cyclodextrin in 50ml of N,N-dimethylformamide and stir at 75°C for 60 minutes to dissolve completely. Add 20g of melamine borate microcapsule red phosphorus into 150ml of N,N-dimethylformamide, and stir at 75°C for 60 minutes to make it uniformly dispersed in the solution. The above two solutions were mixed and stirred for another hour, and then 0.03 mol of diphenylmethane diisocyanate (MDI, or a trimer of diphenylmethane diisocyanate) was added dropw...

Embodiment 3

[0045] Add 20g of red phosphorus, 3.2g of melamine, 1.6g of boric acid, and 0.16g of sodium lauryl sulfate into 150ml of water, stir evenly at 80°C and react for 4 hours at a stirring rate of 400r / min. Then lower the temperature to 40° C., the melamine borate is precipitated, and continue to stir for 3 hours, so that the melamine borate is evenly precipitated on the surface of the red phosphorus, and the stirring rate is 500 r / min. Then vacuum filter, dry and grind to obtain melamine borate microcapsule red phosphorus.

[0046] Dissolve 5 g of β-cyclodextrin in 50 ml of dimethyl sulfoxide, and stir at 75° C. for 60 minutes to completely dissolve it. Add 20 g of melamine borate microcapsule red phosphorus into 150 ml of dimethyl sulfoxide, and stir at 75° C. for 60 minutes to make it uniformly dispersed in the solution. The above two solutions were mixed, stirred for another hour, and then 0.03 mol of hexamethylene diisocyanate (HDI, also a trimer of hexamethylene diisocyanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com