Bi-component polyurea elastic material and application thereof

An elastic material, two-component technology, applied in the field of coatings, to achieve excellent flexibility and self-healing ability, improve the effect of stone chip resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

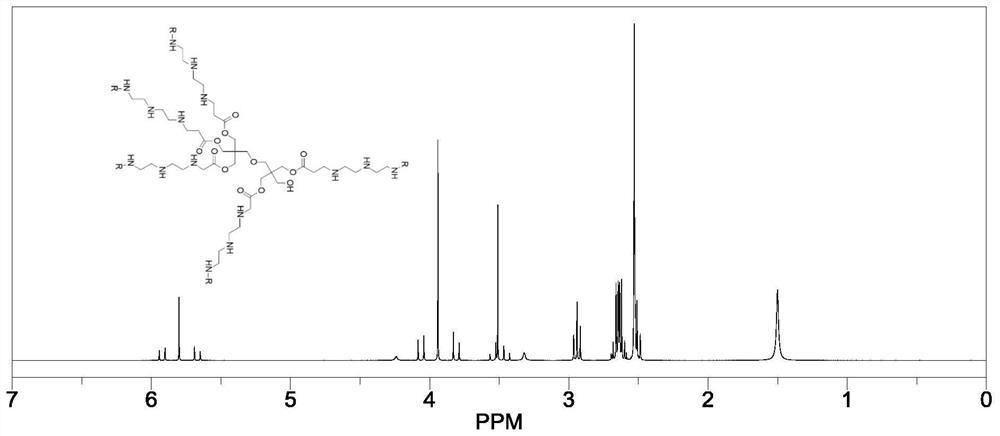

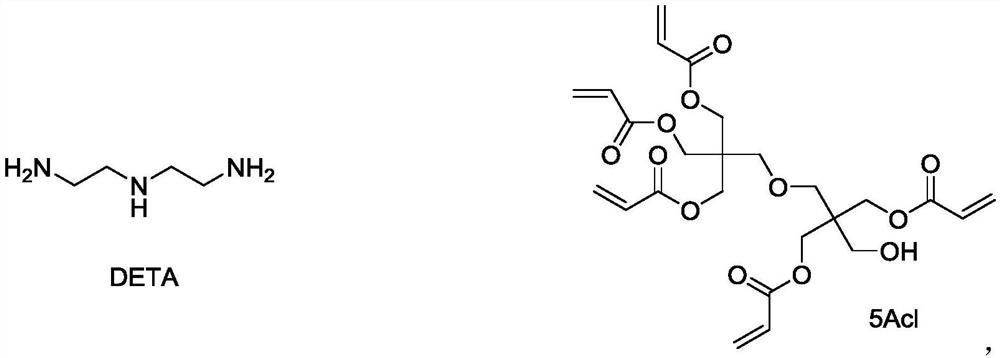

Method used

Image

Examples

Embodiment 1

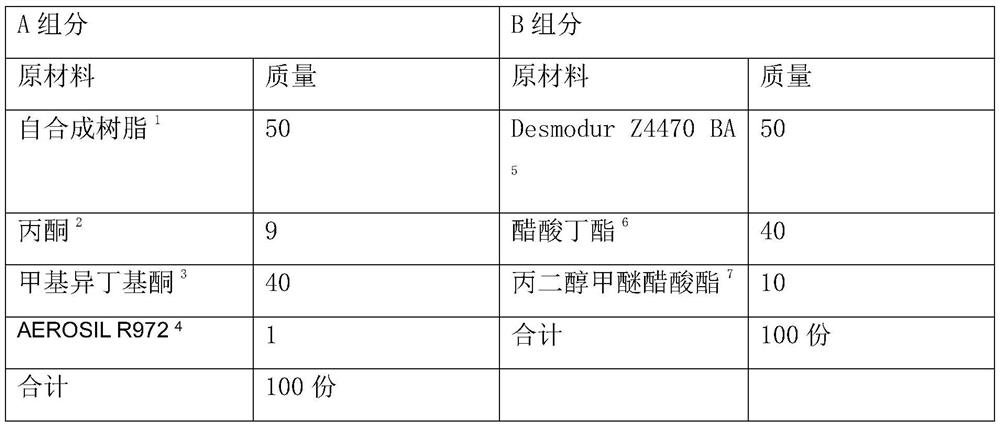

[0043] The present embodiment relates to a kind of two-component polyurea elastic material (varnish), and its composition and quality consumption are as follows table 1:

[0044] Table 1

[0045]

[0046] Remark: 1 It is a self-synthetic resin synthesized according to the aforementioned method herein, with an amine equivalent of 280 g / mol.

[0047] 2,3 Purchased from Sinopharm

[0048]4 Evonik Hydrophobically Modified Fumed Silica

[0049] 5 Covestro's IPDI, NCO content 11.9%, NCO equivalent 353g / mol

[0050] 6,7 Purchased from Sinopec Shell

[0051] The performance test results are shown in Tables 2 and 3 below:

[0052] Table 2

[0053]

[0054] 1,2 The stone impact resistance is considered to be very good.

[0055] table 3

[0056]

[0057]

Embodiment 2

[0059] This embodiment relates to a two-component polyurea elastic material, and its composition and mass dosage are as follows in Table 4:

[0060] Table 4

[0061]

[0062] 1 Neuberger silica (kaolin) from HOFFMANN MINERAL, D50 2um

[0063] 2 Chemours Titanium Dioxide

[0064] 3 Other raw materials are the same as Table 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com