Corrosive agent and corrosion method for metallographic structure of GH4220 high-temperature alloy

A GH4220, metallographic technology, applied in the preparation of test samples, etc., can solve the problems of toxic substances, safety risks, inability to clearly and completely display the metallographic structure of GH4220 superalloy, and ensure the uniformity of the structure. , the effect of improving quality and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

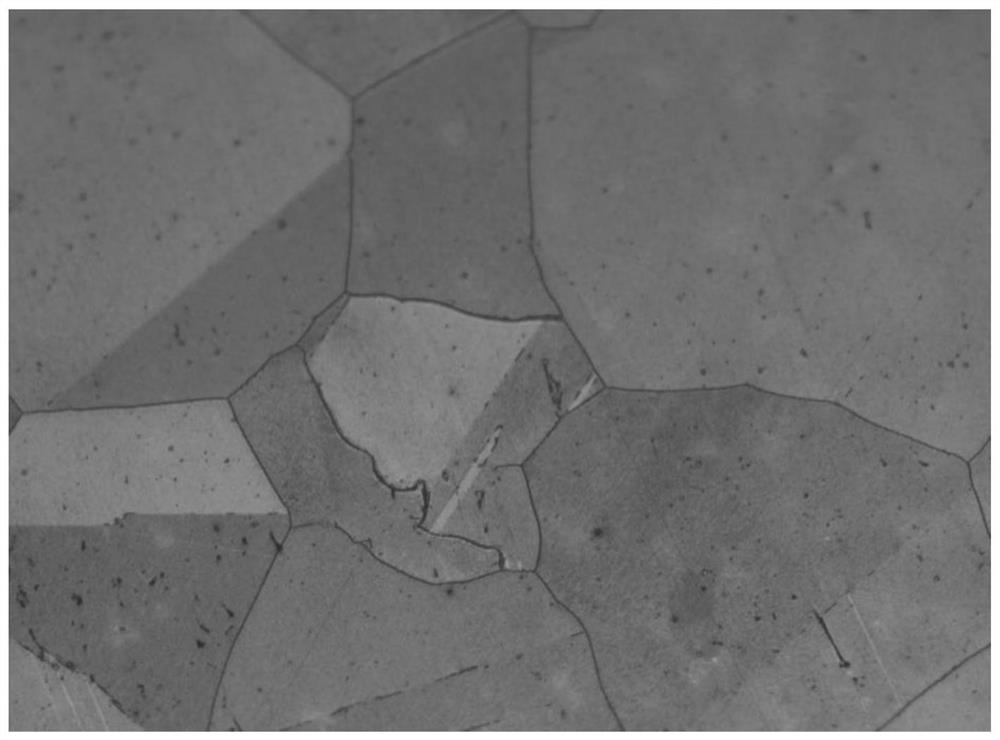

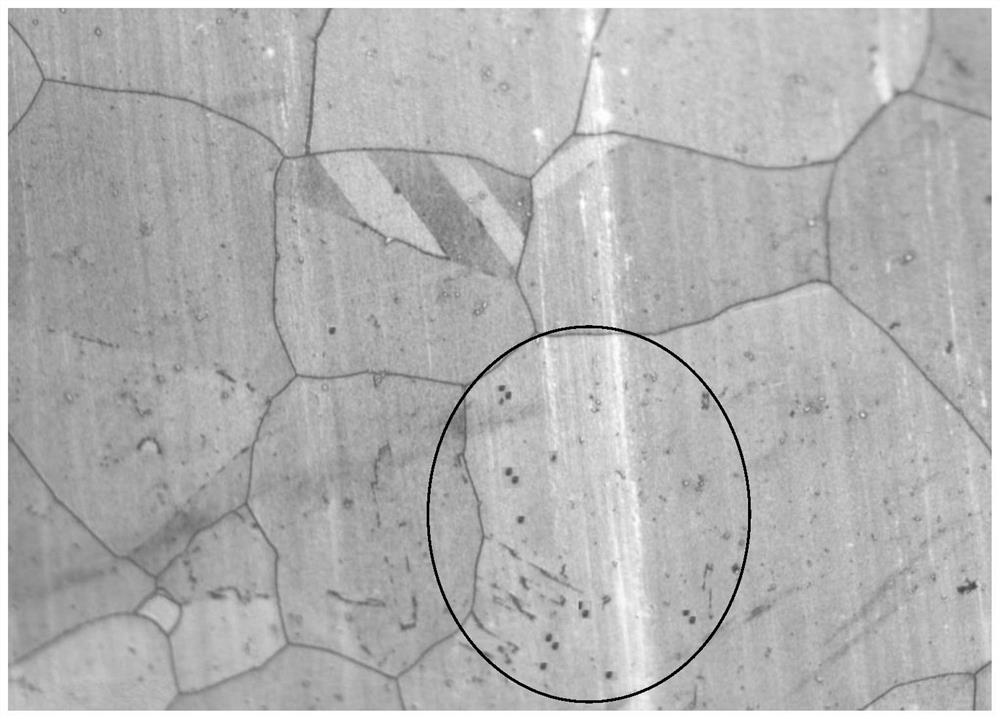

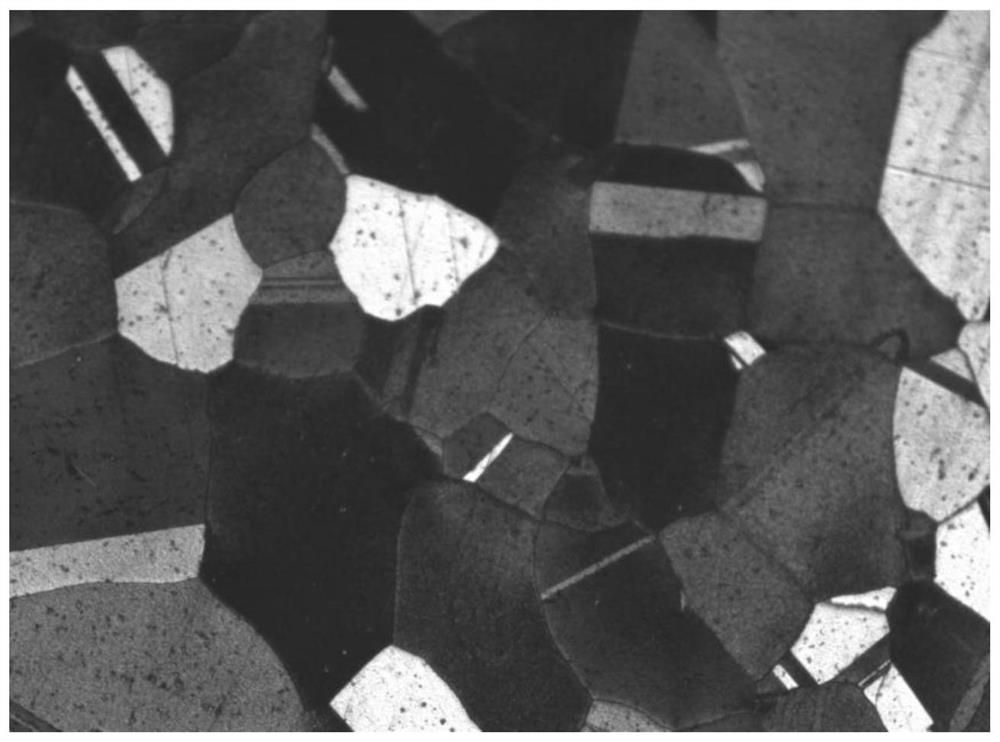

Image

Examples

preparation example Construction

[0050] Specifically, the preparation method of the above-mentioned GH4220 superalloy metallographic structure corrosion agent comprises the following steps:

[0051] Step 1, add concentrated hydrochloric acid into the beaker according to the proportion;

[0052] Step 2, add concentrated nitric acid in the beaker according to the ratio;

[0053] Step 3, according to proportioning, glacial acetic acid is added in the beaker;

[0054] Step 4, add glycerin into the beaker according to the ratio;

[0055] Step 5, stirring evenly and then standing still to obtain a GH4220 superalloy metallographic structure etchant.

[0056] It is worth noting that in the above step 4, the time for standing still is controlled to be 3-5 minutes (for example, 3 minutes, 3.5 minutes, 4 minutes, 4.5 minutes, 5 minutes).

[0057] The present invention also provides a method for corroding the metallographic structure of a GH4220 superalloy, comprising the following steps:

[0058] S1. Longitudinal cu...

Embodiment 1

[0078] This embodiment provides a GH4220 superalloy metallographic structure etchant. The components of the etchant are 40ml concentrated hydrochloric acid + 30ml concentrated nitric acid + 10ml glycerin + 20ml glacial acetic acid.

[0079] Preparation method of corrosive agent:

[0080] Step 1, add 40ml concentrated hydrochloric acid into the beaker;

[0081] Step 2, sequentially add 30ml of concentrated nitric acid, 20ml of glacial acetic acid and 10ml of glycerin into the beaker;

[0082] Step 3. Stir and melt with a glass rod and let it stand for 4 minutes evenly to obtain a GH4220 superalloy metallographic structure etchant.

Embodiment 2

[0084] This embodiment provides a GH4220 superalloy metallographic structure etchant. The components of the etchant are 35ml concentrated hydrochloric acid + 30ml concentrated nitric acid + 10ml glycerin + 18ml glacial acetic acid.

[0085] The preparation method of the etchant is the same as that of Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com