Concrete plaited block base layer of asphalt pavement

An asphalt pavement and concrete technology, which is applied to roads, roads, pavement details, etc., can solve the problems of long construction period, large deflection difference between the blocks on both sides of the joint, and poor plate properties, so as to improve the load transfer capacity of the joint. , Reduce the cost of life and enhance the stability of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

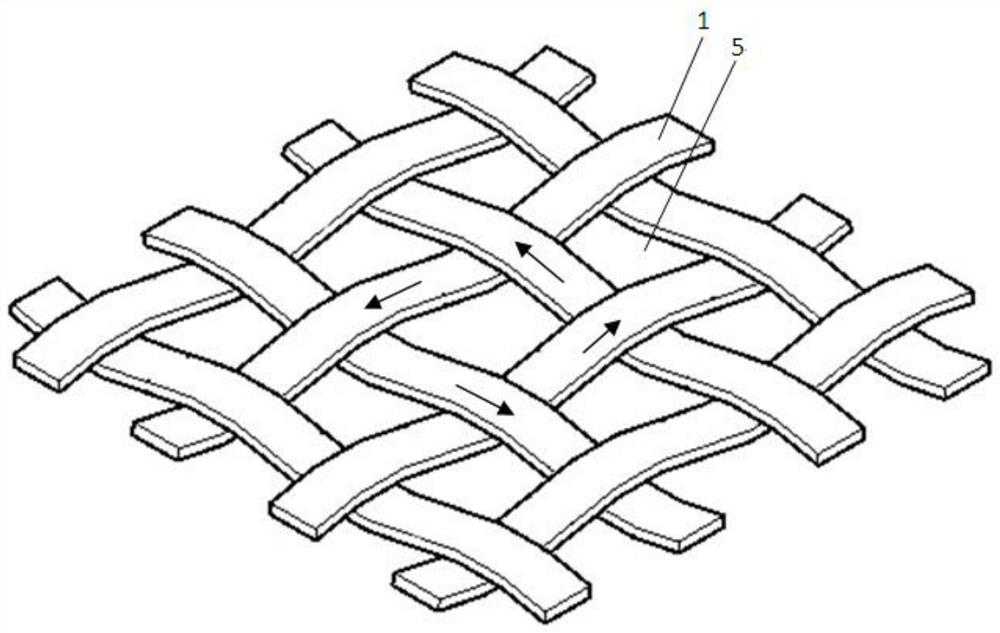

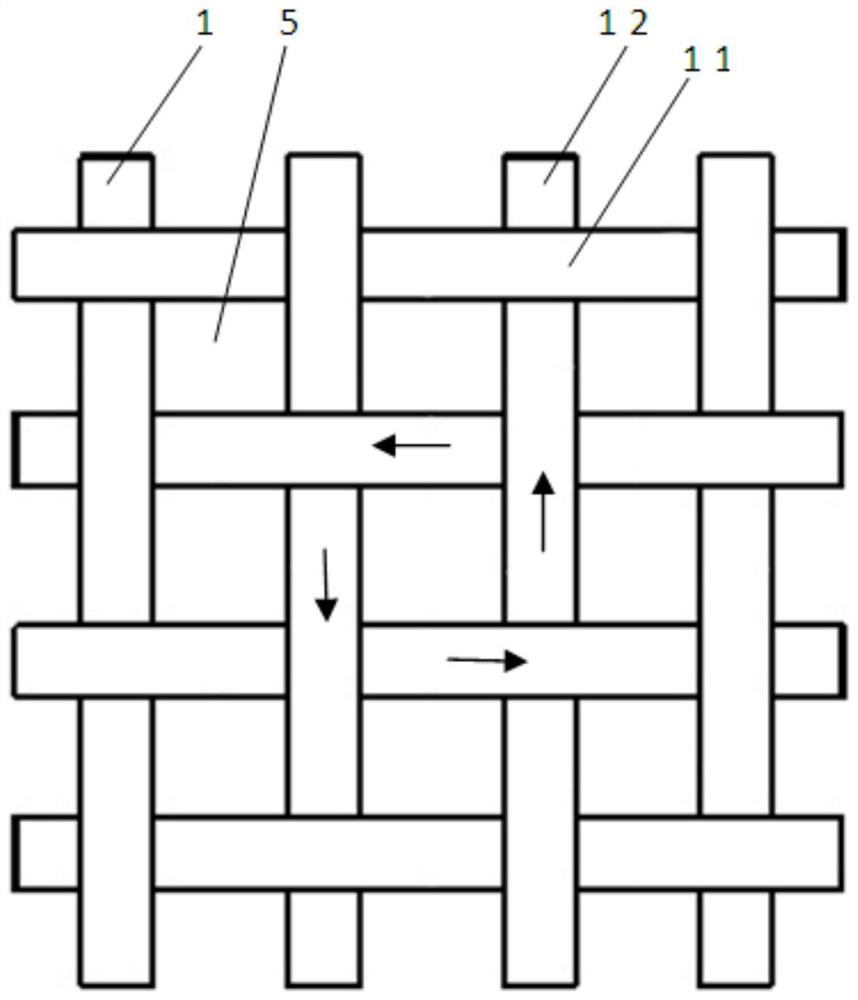

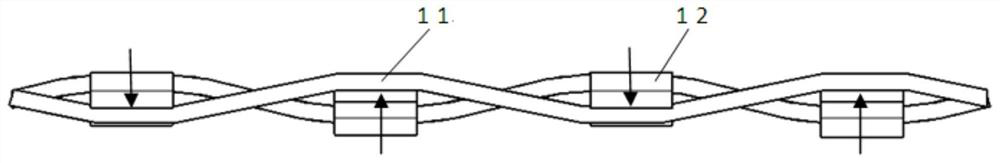

[0057] When the braided body adopts quadrilateral braided blocks: such as Figure 4-7 As shown in -a), the quadrilateral braided block 2 has a rectangular top surface and a bottom surface. Figure four Among the two sides, two symmetrical sides are visible input slopes 22, and the other two symmetrical sides are invisible output slopes 21, and the output surface and the input surface are distributed at intervals. Each internal angle of the block is 90 degrees. Such as Figure 8 As shown, the quadrilateral blocks 2 are assembled to form a mesh 5, and a closed circular output-input relationship is formed around the mesh. The base structure adopts a polygon body with the same number of sides, that is, a quadrilateral block 2 single-block type, and is assembled by superimposing the output surface of adjacent blocks on the input surface.

Embodiment 2

[0059] When the braided body adopts hexagonal braided blocks: as Figure 4-7 -b) as shown. The hexagonal braided block 3 has a hexagonal top surface and a bottom surface, and each internal angle of the braided block is 120 degrees. looking down Figure six Among the two sides, three symmetrical sides are visible input slopes 32, and the other three symmetrical sides are invisible output slopes 31, and the output surface and the input surface are distributed at intervals. Such as Figure 9 As shown, the hexagonal block 3 is assembled to form a mesh 5, and a closed ring-shaped output-input relationship is formed around the mesh 5. The hexagonal block 3 is used for single-block type to assemble by superimposing the input surface of adjacent block output surfaces.

Embodiment 3

[0061] When the block body adopts octagon block 4 and quadrangle block 2, such as Figure 4-7 -c) shown. The octagonal braided block 4 has an octagonal top surface and a bottom surface, and each internal angle of the braided block is 135 degrees. looking down Figure eight Among the two sides, four symmetrical sides are visible input slopes 42, and the other four symmetrical sides are invisible input slopes 41, and the output surface and the input surface are distributed at intervals. Such as Figure 10 As shown, the octagonal block 4 and the quadrilateral block 2 are assembled to form a mesh 5, and a closed circular output-input relationship is formed around the mesh. The octagonal block 4 needs to be combined with the quadrangle block 2 to be assembled and used according to the inclined plane output superposition input surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com