Composite recycled concrete roof panel and preparation method

A technology of composite regeneration and concrete, applied in the field of building materials, can solve problems such as complex process and poor thermal insulation effect, and achieve the effects of saving natural resources, improving thermal insulation effect, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

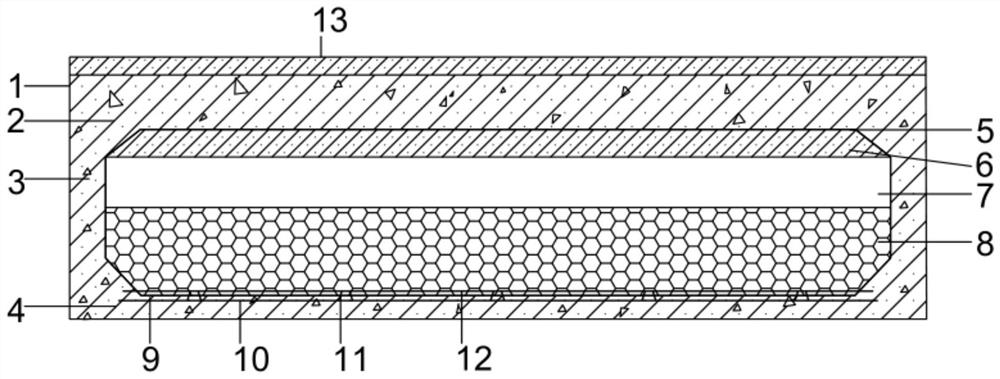

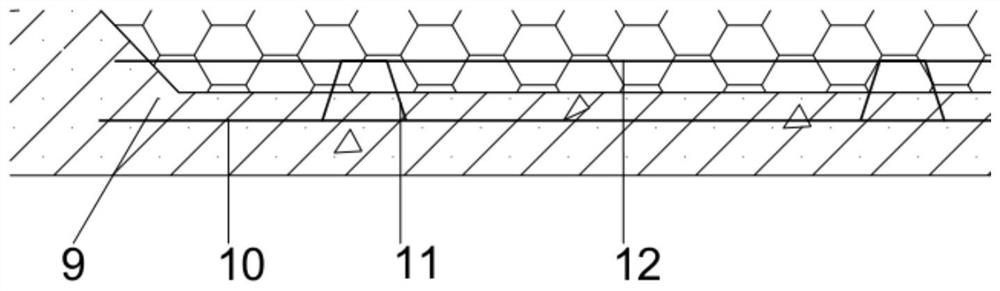

[0075] A composite recycled concrete roof panel includes a board box body 1, the board box body 1 is a cuboid and includes a top board 2, a bottom board 4 and several side boards 3 perpendicular to the top board 2 and the bottom board 4 and parallel to each other, the bottom board 4 And cover plate thickness is 50mm, and side plate 3 thickness is 120mm, and side plate 3 height is 200mm, and the interval between adjacent side plates 3 is 1000mm, and described board box body 1 is provided with a plurality of accommodating chambers 5, so The accommodating chamber 5 is sequentially provided with a mortar layer 6, a ventilation layer 7, a foam layer 8, and a reinforcement layer 9 from top to bottom. The thickness of the mortar layer 6 is 20mm, and 30% salt is mixed in the mortar layer 6. Modified zeolite powder-based humidity control material, the ventilation layer 7 is hollow, the thickness of the ventilation layer 7 is 100mm, and the inner bottom of the reinforcement layer 9 is pr...

Embodiment 2

[0104]A composite recycled concrete roof panel includes a board box body 1, the board box body 1 is a cuboid and includes a top board 2, a bottom board 4 and several side boards 3 perpendicular to the top board 2 and the bottom board 4 and parallel to each other, the bottom board 4 And cover plate thickness is 50mm, and side plate 3 thickness is 120mm, and side plate 3 height is 220mm, and the interval between adjacent side plates 3 is 1000mm, and described board box body 1 is provided with a plurality of accommodating chambers 5, so The accommodating chamber 5 is sequentially provided with a mortar layer 6, a ventilation layer 7, a foam layer 8, and a reinforcement layer 9 from top to bottom. The thickness of the mortar layer 6 is 20mm, and 30% salt is mixed in the mortar layer 6. Modified zeolite powder-based humidity control material, the ventilation layer 7 is hollow, the thickness of the ventilation layer 7 is 100mm, and the inner bottom of the reinforcement layer 9 is pro...

Embodiment 3

[0133] A composite recycled concrete roof panel includes a board box body 1, the board box body 1) is a cuboid and includes a top board 2, a bottom board 4 and several side boards 3 perpendicular to the top board 2 and the bottom board 4 and parallel to each other, the bottom board 4 and the thickness of the cover plate is 50 mm, the thickness of the side plate 3 is 120 mm, the height of the side plate 3 is 220 mm, and the interval between adjacent side plates 3 is 1000 mm, the board box 1 is provided with a number of accommodation chambers 5, The accommodating chamber 5 is sequentially provided with a mortar layer 6, a ventilation layer 7, a foam layer 8, and a reinforcement layer 9 from top to bottom. The thickness of the mortar layer 6 is 20mm, and 30% of Saline modified zeolite powder-based humidity control material, the ventilation layer 7 is hollow, the thickness of the ventilation layer 7 is 100mm, and the inner bottom of the reinforcement layer 9 is provided with severa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com