Three-dimensional noise reduction integrated stove

A technology of integrated stove and noise reduction, applied in the field of integrated stove, can solve the problems of increased fan noise, large noise of the whole machine, limited sound absorption effect, etc., and achieve the effect of ensuring the suction effect, reducing noise, and increasing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

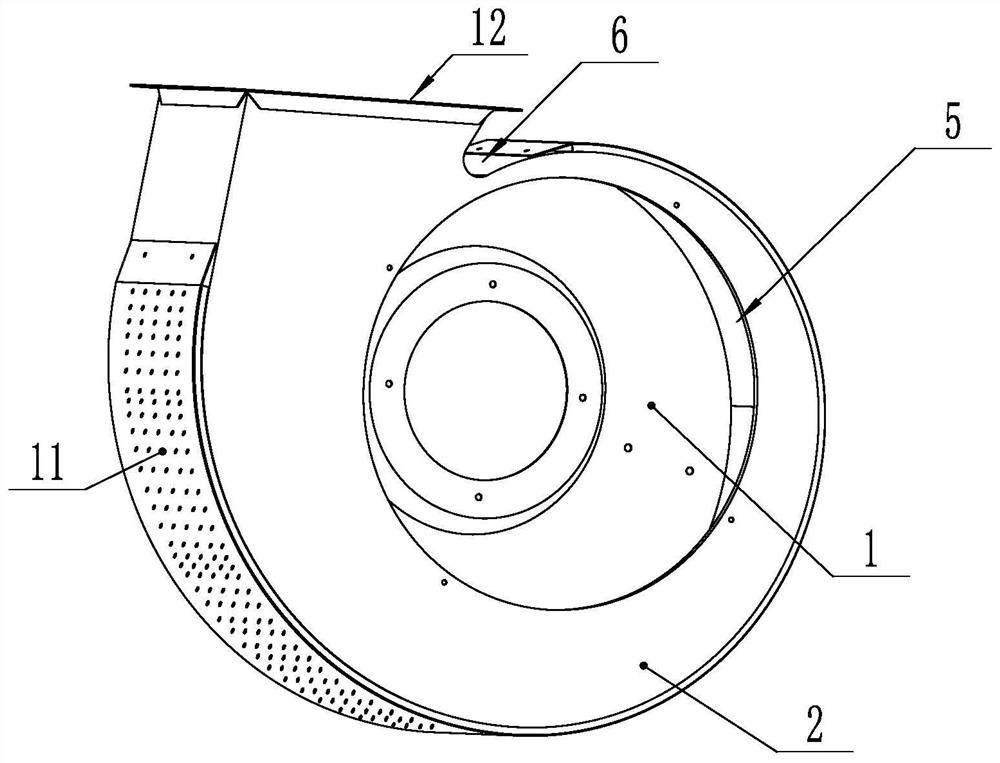

[0055] Such as Figure 5 As shown, inside the fan, in the radial direction of the circumference, the flow field pressure at the rear end of the volute tongue 6 is higher, and the noise frequency band is also higher, and at the air outlet 12, the flow field pressure is lower, and the noise frequency band is also lower.

[0056] Such as Figure 6 As shown, inside the fan, in the axial direction, the flow field pressure at the air inlet 5 is lower, and the noise frequency band is also lower. The closer to the fan volute rear plate 2, the higher the flow field pressure, and the higher noise frequency band. comprehensive Figure 5 , Figure 6 As shown, the flow field inside the fan is relatively complex, and the frequency range of the noise is also wide.

[0057] In order to reduce noise, the present invention adopts following structure:

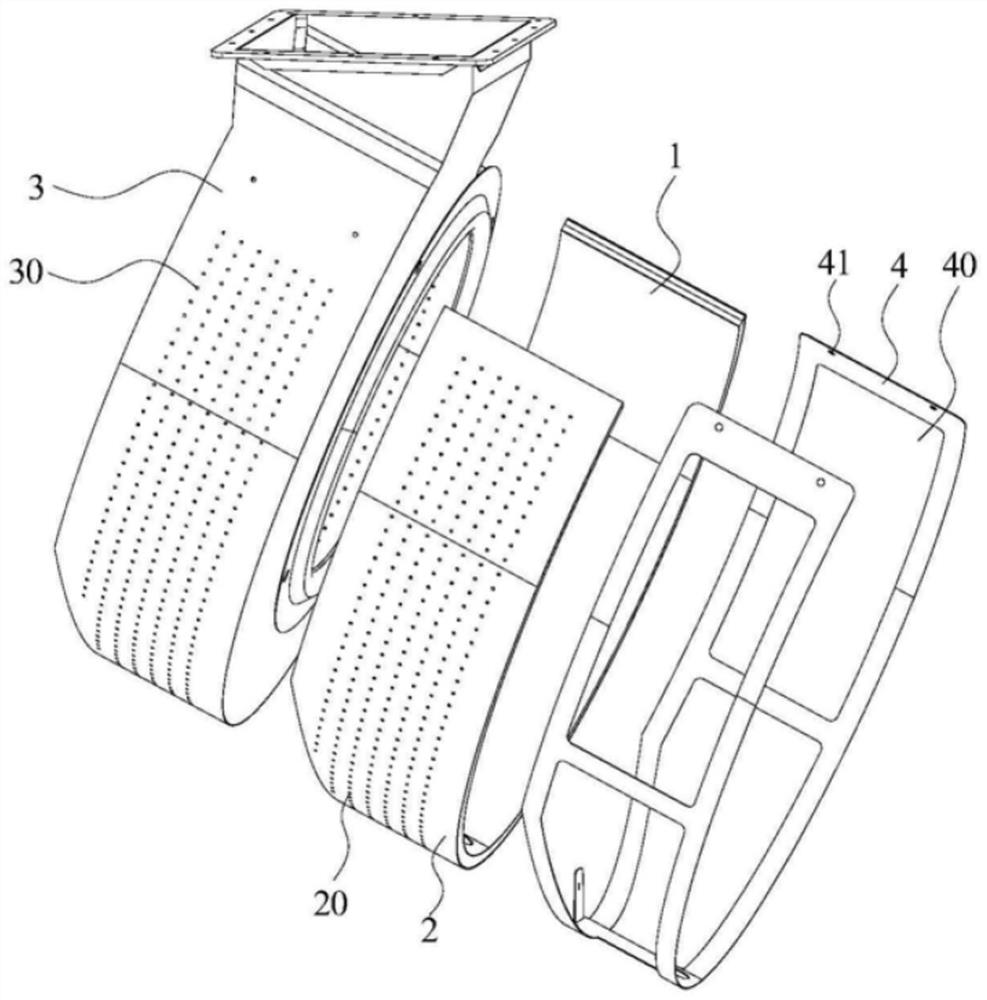

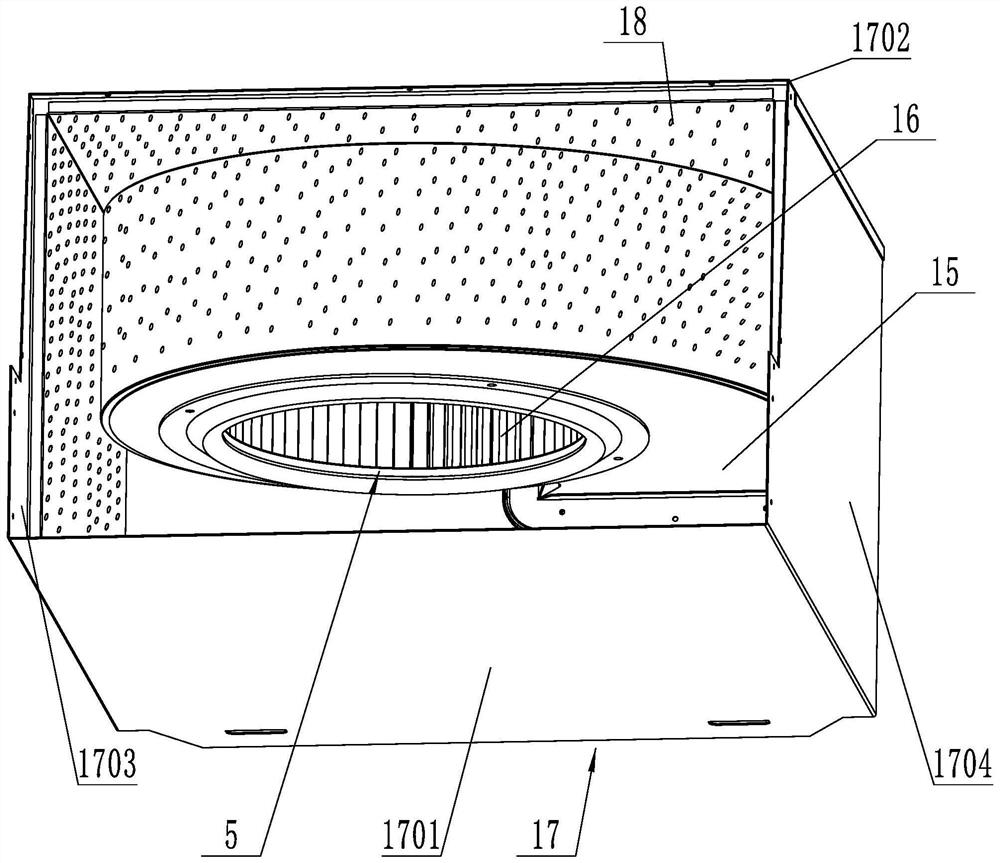

[0058] Such as figure 2 , 3 , 4, 7, and 8, the present invention includes a fan assembly, a fan box 17 for accommodating the fan assembly...

Embodiment 2

[0074] Such as Figure 9 As shown, the same place as Embodiment 1 will not be repeated, the difference is:

[0075] The second through hole 1101 is a square hole whose width matches the width of the fixing plate 11; the frame width of the square hole is W, where 10mm≤W≤30mm. The second through hole 1101 matches the width of the fixing plate 11, which reduces the shielding of the first sound-absorbing layer 4, and is beneficial to improve the penetration rate of noise to the first sound-absorbing layer 4; the frame of the fixing plate 11 can ground the first sound-absorbing layer 4 Pressing on the volute side plate 3 enables the first sound-absorbing layer 4 to cover the volute side plate 3 to ensure the noise reduction effect and the reliability of the connection.

Embodiment 3

[0077] Such as Figure 10 , 11 As shown, for the convenience of manufacturing, the volute side plate 3 is divided into multiple regions along the circumferential direction, each region is divided into multiple units, the first through holes 301 in the same unit have the same spacing, and the first through holes of adjacent units The pitches of the holes 301 are different to form units with different through-hole ratios; the pitches of the first through holes 301 of corresponding units in different regions are the same. Since the dimension in the circumferential direction of the volute side plate 3 is much larger than the radial dimension of the volute side plate 3, by dividing it into multiple areas in the circumferential direction, one area corresponds to one stamping of the stamping die, and multiple areas correspond to the stamping of the stamping die. Multiple times of stamping can realize the punching work of the first through hole 301 of the volute side plate 3 by movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com