Wafer box in-out conveying device for vertical oxidation furnace

A technology of conveying device and oxidation furnace, applied in furnaces, furnace components, conveyor objects, etc., can solve the problems of low precision, low production efficiency, slow counting efficiency, etc., and achieve a simplified detection process, a high degree of automation, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

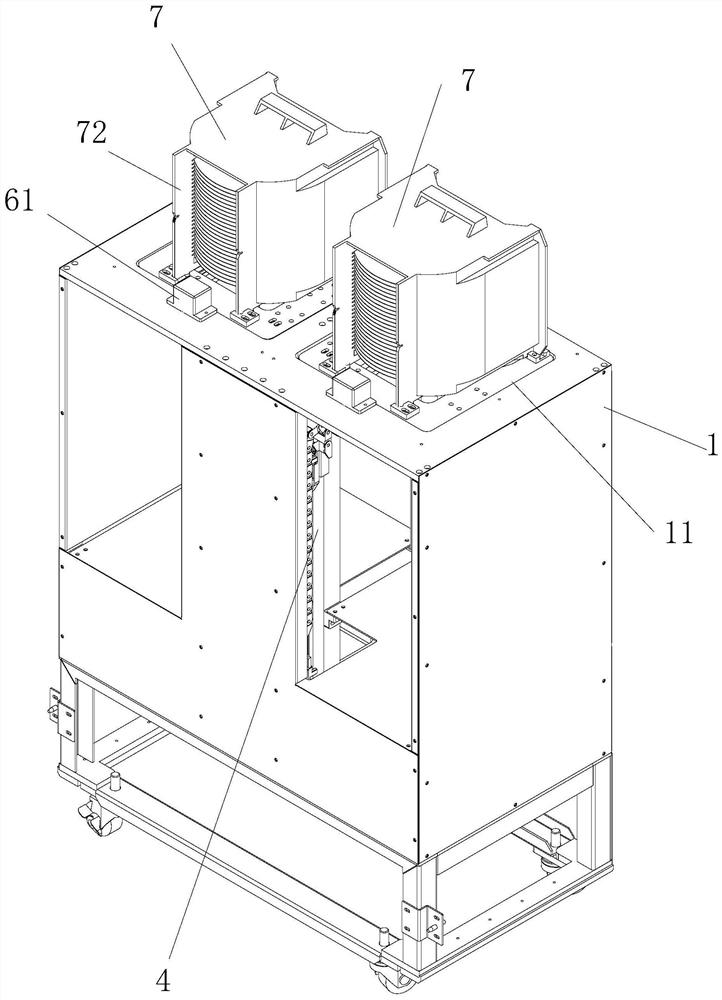

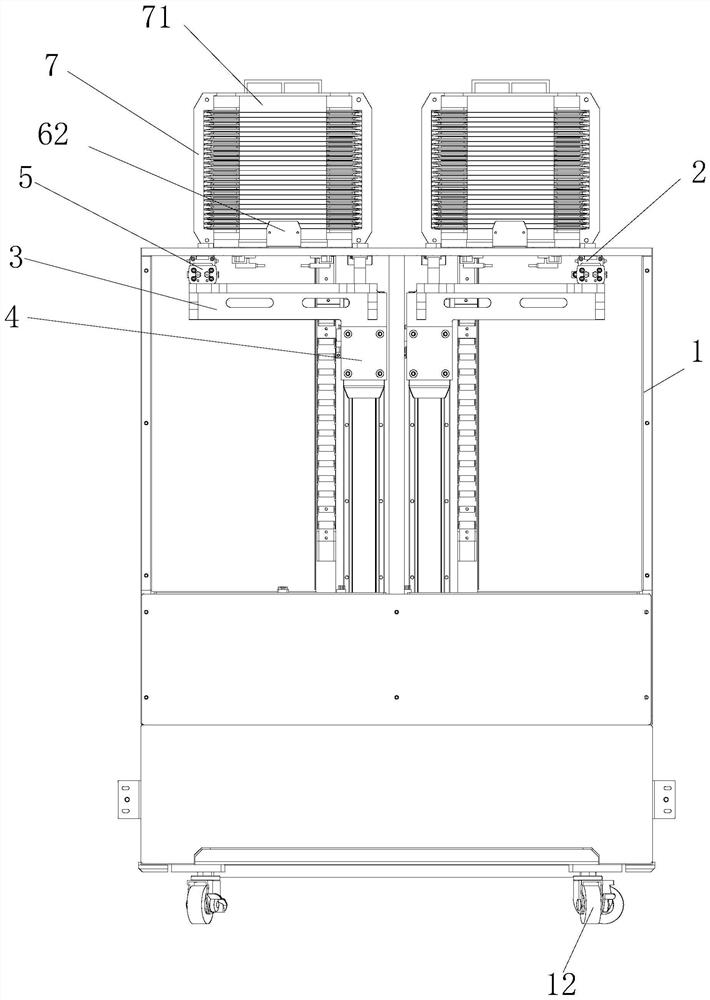

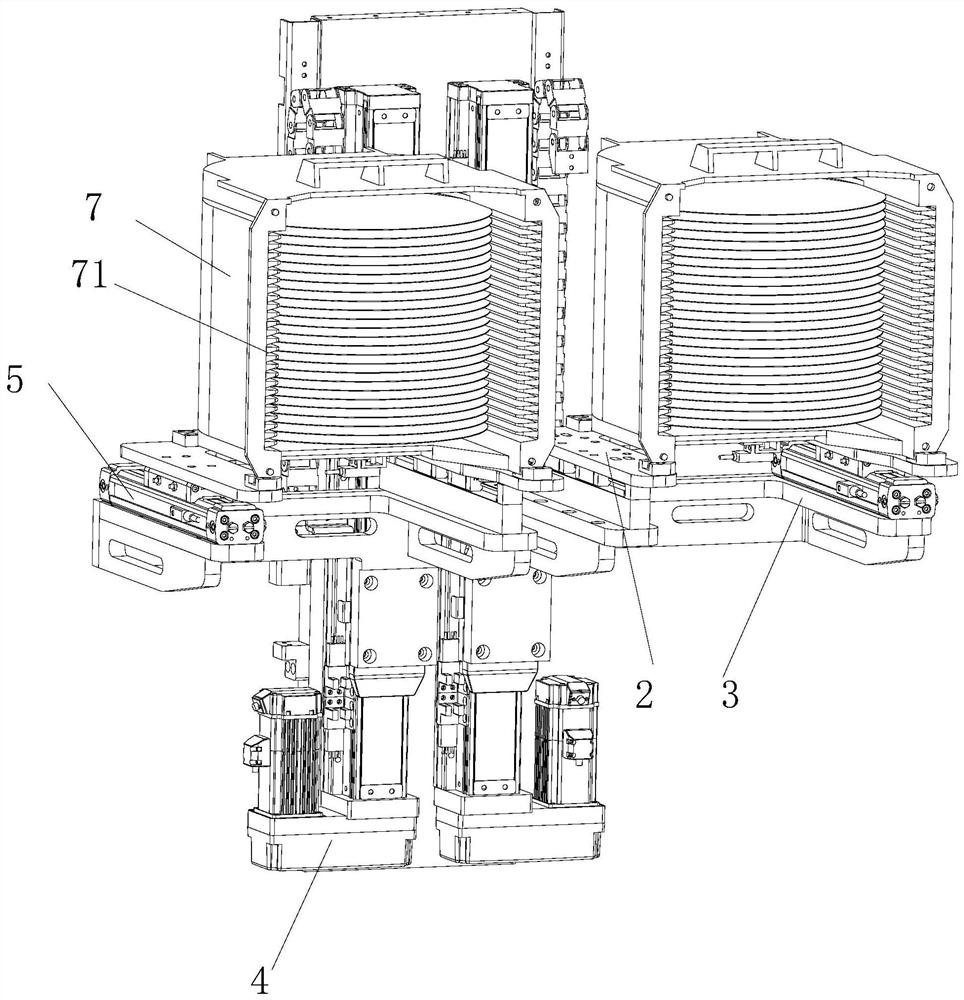

[0026] Such as Figure 1 to Figure 5 As shown, the cassette transfer device used in the vertical oxidation furnace of this embodiment includes a frame 1, a cassette loading platform 2, a lifting platform 3, a lifting mechanism 4, a pushing mechanism 5 and a counting unit, and the lifting mechanism 4 is designed In the frame 1, the lifting platform 3 is arranged at the driving end of the lifting mechanism 4, the cassette carrying platform 2 and the pushing mechanism 5 are arranged on the lifting platform 3, and the pushing mechanism 5 is used to push the cassette carrying platform 2 out of the frame 1 The top of the frame 1 is provided with an avoidance groove 11 for the cassette carrier 2 to pass through. The counting unit includes a laser emitting receiving unit 61 and a reflector 62. In this embodiment, the laser emitting and receiving unit 61 is preferably a photoelectric sensor integrating transceiver. The pushing mechanism 5 can be arranged on the frame 1 or on the lifti...

Embodiment 2

[0041] The difference between the sheet cassette in and out conveying device for the vertical oxidation furnace of the present embodiment and that of Embodiment 1 is:

[0042] In this embodiment, the counting unit includes a laser emitting unit 61 and a laser receiving unit 62, preferably two through-beam photoelectric sensors, one photoelectric sensor emits laser light, and the other photoelectric sensor receives laser light. Once sending and receiving, according to the photoelectric sensor of the receiver to receive the laser light changes, it is judged whether there is a silicon chip in the card slot inside the cassette 7 .

[0043] The rest not described are basically the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com