Titanium alloy and titanium alloy watch appearance part manufacturing method

A manufacturing method, a technology of titanium alloy, applied in the manufacture of tools, clocks, casings, etc., can solve the problems of material performance being greatly affected, and achieve the effects of good wearing comfort, increased compression rate, and reduced difficulty of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

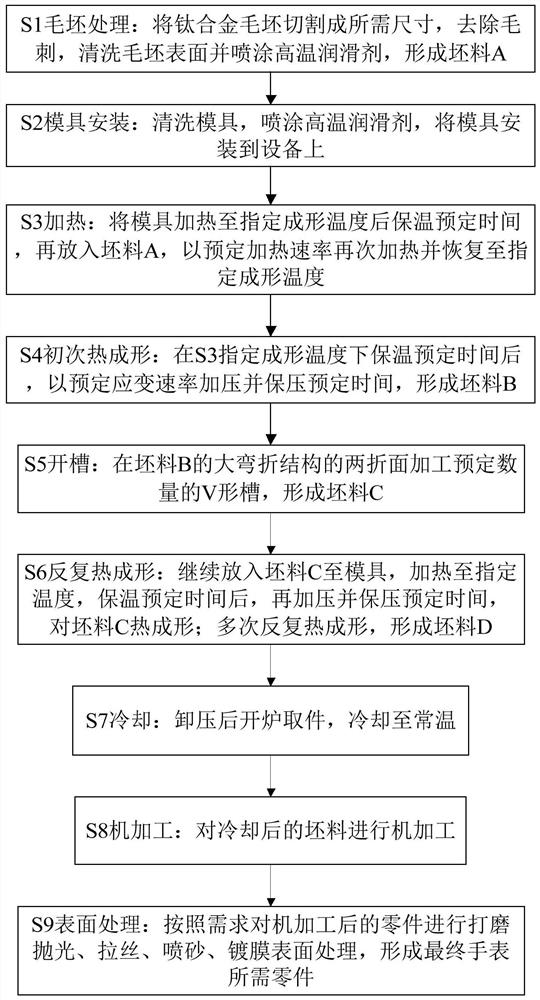

[0064] In this embodiment, the titanium alloy includes the following components in weight percentage: 6.32% of Al, 0.12% of Si, 1.63% of V, 2.56% of Zr, 1.37% of Mo, 3.4% of Sn, 82.99% of Ti, 0.8% Nb and 0.81% other small amount of impurity elements, using the titanium alloy composed of the above components as the raw material, the processed product has a bright and beautiful surface appearance, excellent performance and high quality. Using the above-mentioned titanium alloy material, the present embodiment makes a kind of titanium alloy watch appearance parts processing method as follows Figure 5 The watch case shown specifically includes the following steps:

[0065] S1 blank treatment: Cut the titanium alloy blank to the required size, remove the burrs by sanding, then clean the surface of the blank with alcohol and spray high-temperature lubricant to form blank A.

[0066] S2 mold installation: clean the mold and spray boron nitride lubricant, then install the mold on th...

Embodiment 2

[0077] In this embodiment, the titanium alloy comprises the following components in weight percentage: 5.76% of Al, 0.35% of Si, 2.1% of V, 2.74% of Zr, 0.89% of Mo, 3.52% of Sn, 82.21% of Ti, 1.0% Nb, 1.43% other minor and impurity elements, using the titanium alloy composed of the above components as the raw material, the processed product has a bright and beautiful surface appearance, excellent performance and high quality. Using the above-mentioned titanium alloy material, the present embodiment makes a kind of titanium alloy watch appearance parts processing method as follows Image 6 The bottom cover of the watch shown specifically includes the following steps:

[0078] S1 blank treatment: Cut the titanium alloy blank to the required size, remove the burrs by sanding, then clean the surface of the blank with alcohol and spray high-temperature lubricant to form blank A.

[0079] S2 mold installation: clean the mold and spray boron nitride lubricant, then install the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com