Sewage pool solid impurity degradation system

A solid impurity and sewage tank technology, applied in water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of shortening the sewage treatment cycle, slow sedimentation cycle, health hazards, etc., to improve The effect of sewage treatment efficiency, avoiding the increase of air pressure, and improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

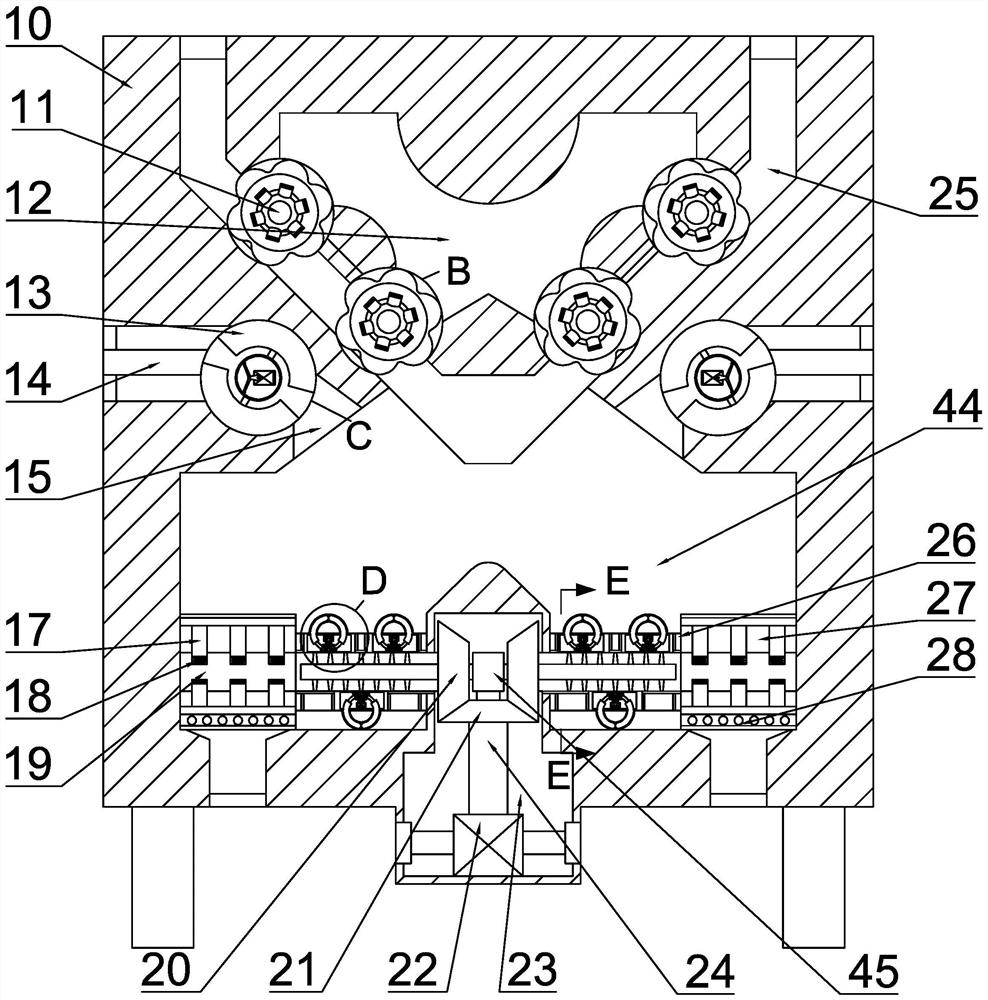

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

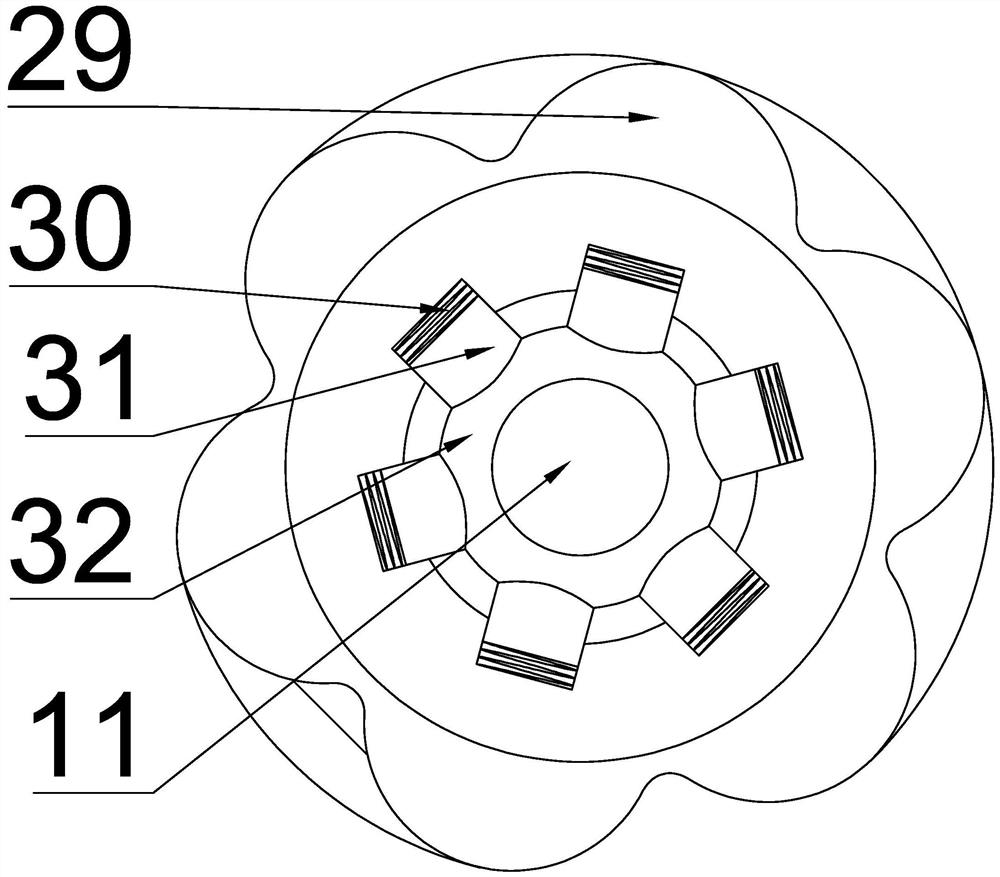

[0027] Such as figure 1 As shown, a system for degrading solid impurities in a sewage tank includes a housing 10. A spreading chamber 25 is provided on the upper side of the housing 10, and a spreading device is arranged in the spreading chamber 25. The spreading device is used for spreading lime powder to sewage and its impact on sewage. When the device is placed, one of the inner chambers is closed. The lower side of the housing 10 is provided with a separation chamber 27, and a separation device is provided in the separation chamber 27. The separation device is used for the separation of solid impurities and liquids in the sewage. The lower side of the housing 10 is provided with a degradation chamber. Box 44, the degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com