Dividing wall type heat exchanger and application

A technology of heat exchanger and heat exchange plate, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat transfer modification, etc., can solve the problems of poor cooling effect, uneven cooling, large temperature difference, etc., and achieve heat transfer temperature difference Small, compact structure, small temperature difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

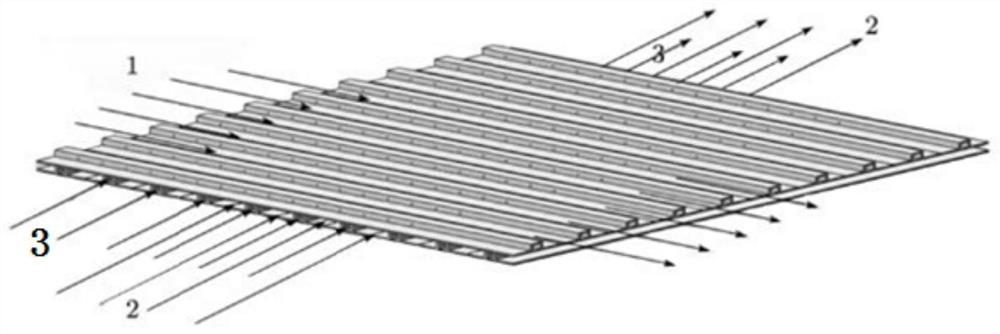

[0048] figure 1 It is a schematic diagram of the overall composition and structure of a microchannel type indirect evaporative cooling plastic heat exchanger described in this application. figure 2 It is a schematic diagram of the composition and structure of the flow channel of the heat exchanger described in this application. image 3 It is a partial cross-sectional schematic diagram of the composition structure of the heat exchange plate and inter-plate ribs described in this application. Figure 4 It is a partial cross-sectional schematic diagram of the composition structure of the heat exchange plate, heat exchange microchannel, intercostal flow channel and nozzle described in this application. like Figure 1~4As shown, a micro-channel type indirect evaporative cooling plastic heat exchanger described in the present application includes: a primary air channel is the first air channel 1, and a secondary air channel is the second air channel 2, which is used for the indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com