Veterinary drug bottle leak detection device

A technology for leak detection and medicine bottles, which is applied in the direction of liquid tightness measurement using liquid/vacuum, can solve problems such as veterinary drug leakage, and achieve the effect of easy leakage repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In the prior art, when it is detected that the veterinary drug bottle 3 is damaged, it is necessary to move the veterinary drug bottle 3 from the first conveyor belt 112 to a specially set leak repairing station, and then the operator uses a helium mass spectrometer leak detector to check the veterinary drug again. Bottle 3 carries out leak detection, to confirm the specific damage position of veterinary medicine bottle 3, then veterinary medicine bottle 3 is carried out leakage repair, obviously, this mode is not only loaded down with trivial details operation, also wasted manpower and material resources.

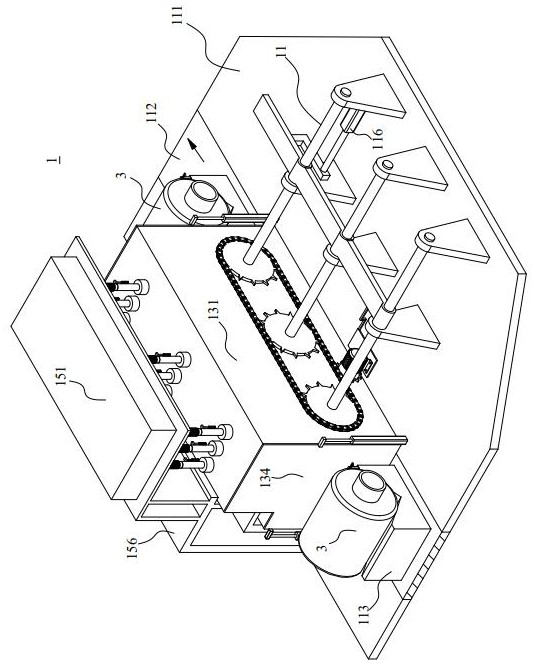

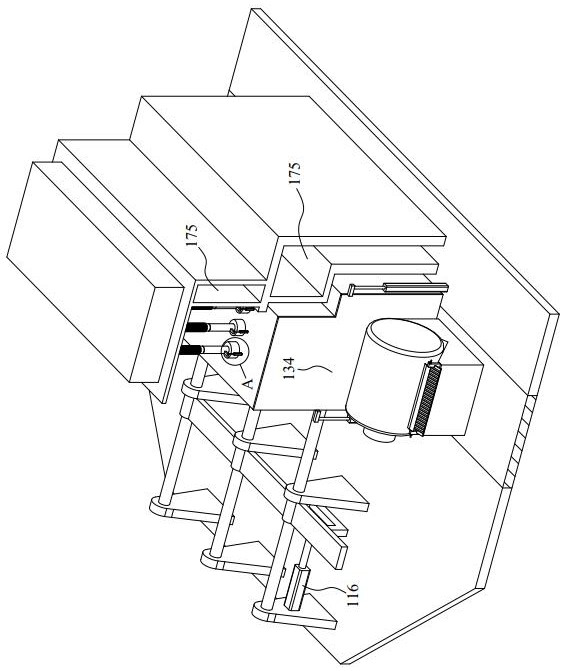

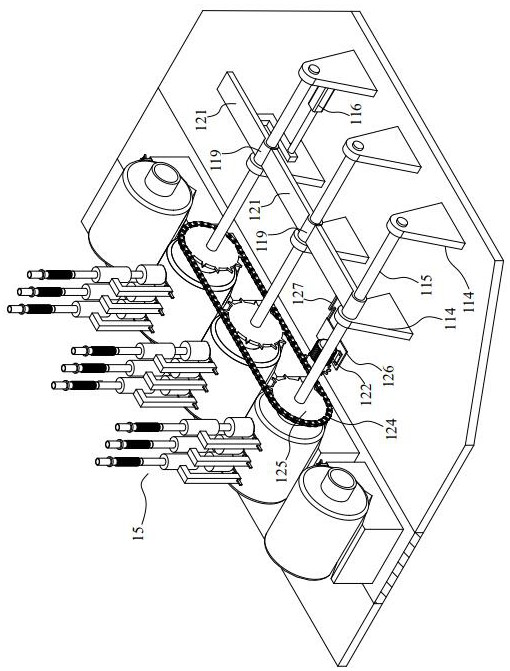

[0045] Please refer to Figure 1-Figure 12 , the present embodiment provides a leak detection device 1 for veterinary medicine bottles, which mainly includes: a support mechanism 11 , a leak detection mechanism and a leak repair mechanism 15 . Through the setting of the support mechanism 11 and the leak detection mechanism, it is convenient to carry out leak detecti...

Embodiment 2

[0060] This embodiment is a further improvement made on the basis of Embodiment 1.

[0061] Please refer to Figure 1-Figure 14 , The veterinary drug bottle leak detection device 1 also includes a second conveyor belt 181 and a quick-drying box 182 . The second conveyor belt 181 is perpendicular to the first conveyor belt 112, and the veterinary drug bottle 3 can pass through the quick-drying box 182 transversely, and the quick-drying box 182 is arranged on the top of the second conveyor belt 181, and a blower 183 is installed on the quick-drying box 182, The blower 183 is connected with an air outlet pipe 184 , and the air outlet pipe 184 is located in the quick-drying box 182 . The veterinary drug bottle 3 through leak detection and mending can be transported in the quick-drying box 182 by the second conveyor belt 181, and the blower 183 blows the wind to the veterinary drug bottle 3 to accelerate the solidification of the plastic on the veterinary drug bottle 3.

[0062]T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com