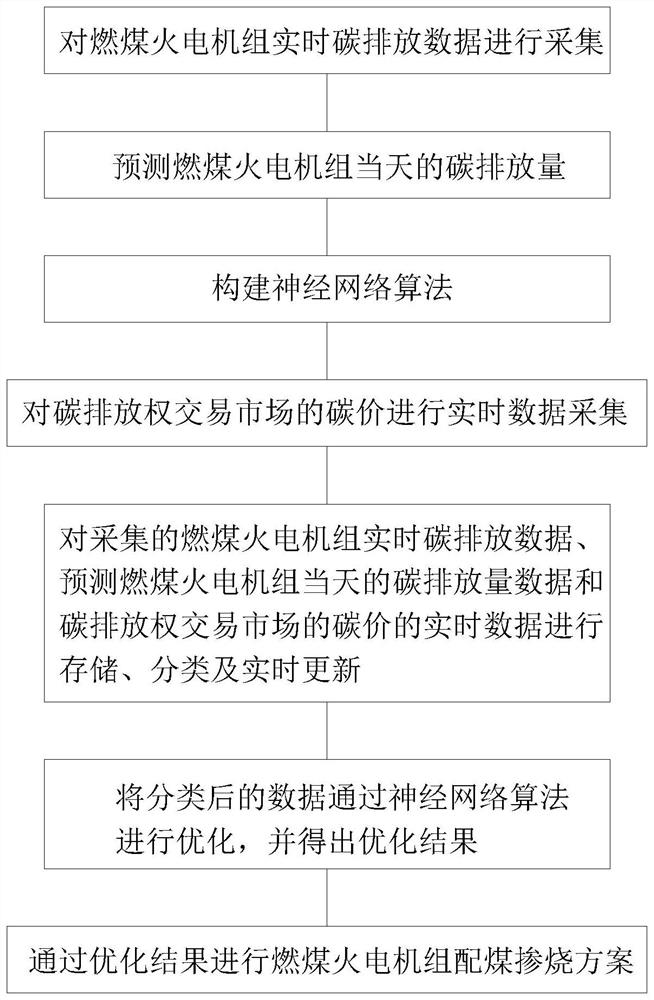

Coal blending combustion optimization decision-making method based on real-time carbon emission monitoring of thermal power generating unit

A technology of thermal power units and decision-making methods, applied in the direction of neural learning methods, predictions, instruments, etc., can solve the problems of rising coal consumption rate of power generation, boiler efficiency decline, etc., and achieve the effect of energy saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

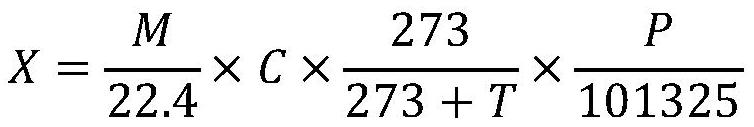

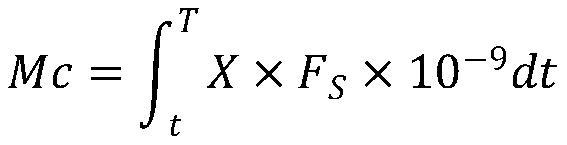

[0118] According to the device for collecting real-time carbon emission data of coal-fired thermal power units, a thermal power plant collects relevant data from the flue gas discharge chimney of coal-fired thermal power units and the coal blending based on real-time carbon emission monitoring of thermal power units Combustion optimization decision-making method, for all types of coal in thermal power plants, monitor and obtain the carbon emissions of thermal power plants in the previous 14 days, the types and amounts of coal used in thermal power plants, and corresponding chemical and physical data. As shown in Table 1.

[0119] Table 1 Carbon emissions and coal consumption parameters of thermal power plants in the first 14 days

[0120]

[0121]

[0122] On the fifteenth day, the type and amount of coal used by the thermal power plant and the corresponding chemical and physical data. As shown in table 2.

[0123] Table 2 Coal Use Data of Thermal Power Plants on the Fif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com