Magnetic core surface defect detection method based on deep learning

A deep learning and detection method technology, applied in the field of computer vision, can solve the problems of missed detection, many false detections, and low quality of magnetic core defect detection, and achieve the effect of enhancing authenticity, expanding quantity and diversity, and reducing training time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

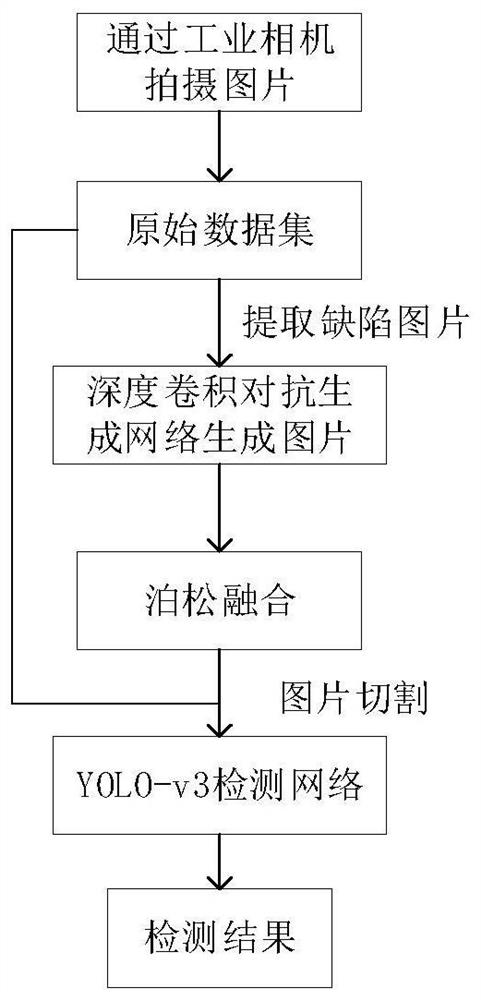

[0053] The principle of the present invention is as follows: first, the front and back pictures of the magnetic core surface are obtained by an industrial camera and preprocessed to obtain an original data set, and then the magnetic core defect part is extracted from the original data set, and the extracted defect picture is used as a real The data is sent to the improved deep convolutional confrontation generation network for training to generate a new defect image, and then the defect image is used as the target image and the good magnetic core image for image fusion through Poisson fusion to form an enlar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com