A kind of production equipment of water-resistant living bacteria popping beads

A kind of production equipment, the technology of popping beads, applied in the direction of gel preparation, mixer with rotating stirring device, colloid chemistry, etc., can solve the problems of low freeze-drying effect of particles, affecting vitality, different soaking time, etc., to achieve Solve stability problems, avoid sinking, improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

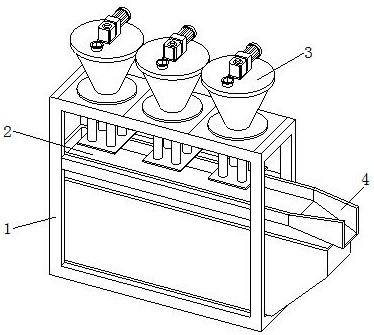

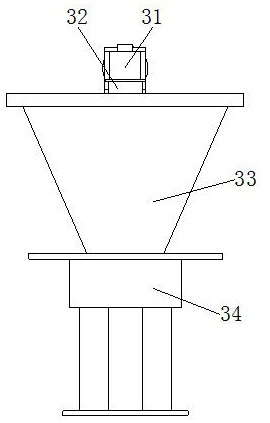

[0025] as attached figure 1 to attach Figure 5 Shown:

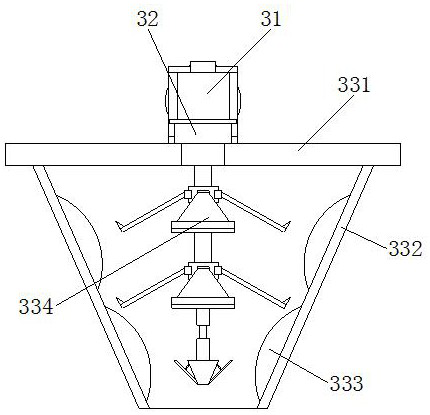

[0026] The present invention is a kind of production equipment of water-resistant living bacteria detonation beads, and its structure comprises a support frame 1, a conduction plate 2, a material mixing device 3, and a discharge port 4, and the inner middle end of the support frame 1 is welded with a conduction plate 2, and The mixing device 3 is fixedly installed on the top of the support frame 1, the conduction plate 2 is located below the mixing device 3, the discharge port 4 is welded on the right end of the conduction plate 2, and the mixing device 3 includes a motor 31, a feed pipe 32. Stirring mechanism 33, forming structure 34, the motor 31 is installed on the upper end surface of the stirring mechanism 33, and the feeding pipe 32 is embedded and installed on the top of the stirring mechanism 33 and communicates with each other, and the lower end of the stirring mechanism 33 is fixedly installed with a forming s...

Embodiment 2

[0033] as attached Figure 6 To attach Figure 8 Shown:

[0034] Wherein, the molding structure 34 includes a material guide plate 341, a soaking mechanism 342, and a lower row mechanism 343. The material guide plate 341 is installed on the lower end of the mixing drum 332 and communicates with each other. Mechanism 342, the lower end of the material guide plate 341 is embedded with a lower row mechanism 343 and communicates with each other. The soaking mechanism 342 is located above the lower row mechanism 343. There are four row mechanisms 343, which are distributed in four positions at the bottom of the material guide plate 341, so as to improve the dispersion and discharge of the soaked and molded popping beads.

[0035] Wherein, the soaking mechanism 342 includes a liquid storage bucket 42a, a cylinder 42b, a lifting drain plate 42c, and a telescopic plate 42d. The middle part of the upper end of the plate 42c is welded, the telescopic plate 42d is installed on the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com