Method for uniformly controlling quality parameters of cold-rolled strip steel

A technology of cold-rolled strip steel and quality parameters, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems that the parameters of liquid materials cannot match the parameters of solid materials, length changes, process control deviations, etc., to achieve Improve product process stability control and enterprise economic benefits, fast and convenient analysis, and the effect of liberating labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

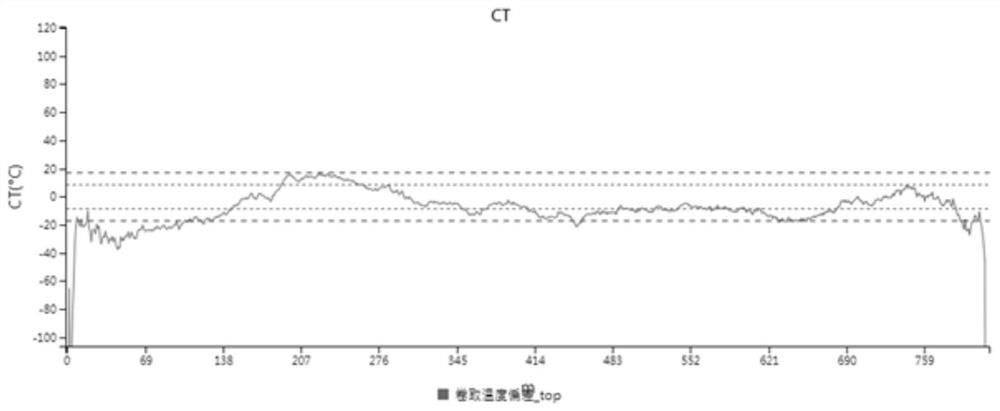

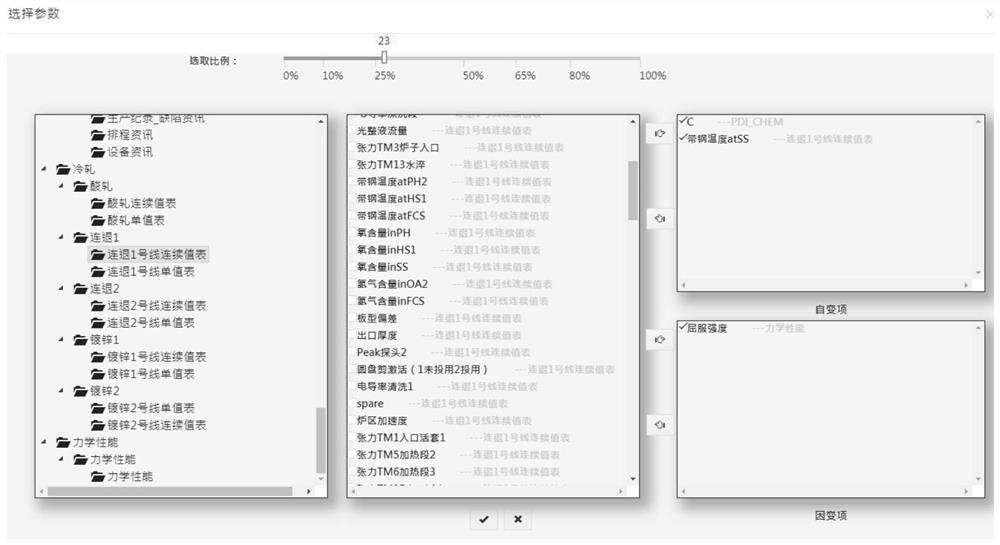

[0112] EXAMPLES: Analysis affects the parameters of DC03 performance tensile strength and yield strength performance, with average value analysis of product performance, continuous value includes hot rolling winding temperature, an average of retreat average heat temperature, single point The value of the steel components C, Si, Mn, and select 30 sets of data.

[0113] Table 1 Analyze data in detail (continuous value taking average data)

[0114]

[0115]

[0116] Table 2 analysis results

[0117]

[0118]

[0119]

[0120] The above analysis results are derived by linear regression, since linear regression is a known mathematical knowledge, and there is no method of educating linear regression here.

[0121]Through analysis results, DC03 products, yield strength, tensile strength and selection of hot rolled winding temperature average, continuous retreat average thermal temperature average; yield strength and C, Si element content have weak correlation Unattractive with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com