Assembly process of sensors

An assembly process and sensor technology, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of low work efficiency, low assembly accuracy, and high labor intensity of staff, and achieve high assembly efficiency, high assembly accuracy, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The embodiments of the present invention will be described in further detail below through specific examples.

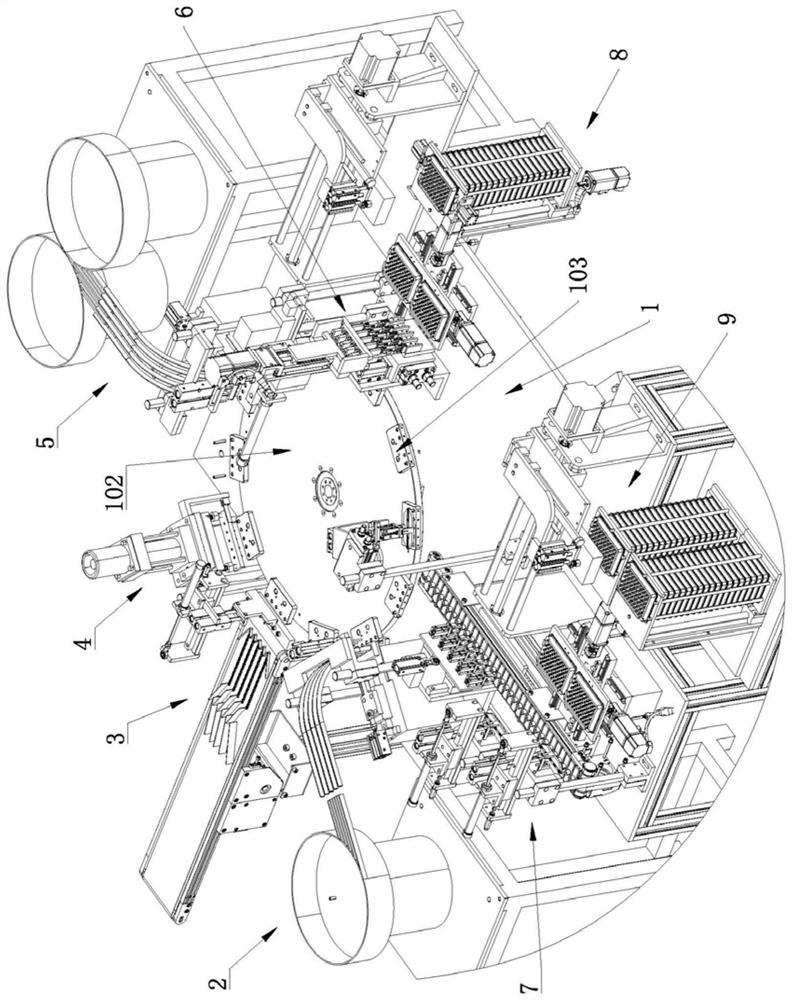

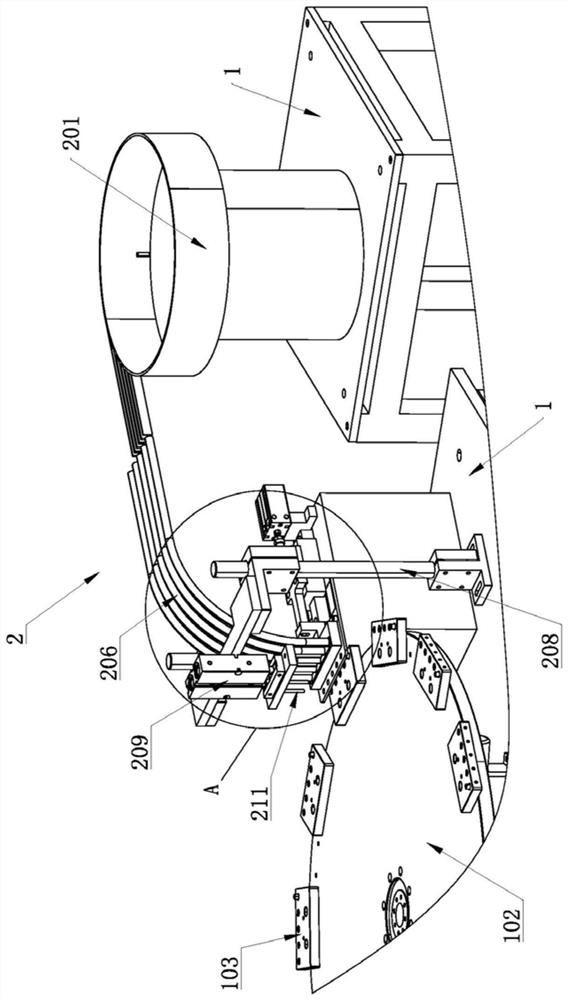

[0065] Such as figure 1 As shown, a sensor assembly process includes an assembly base, and the assembly base is intermittently transported in the following sequentially implemented processes;

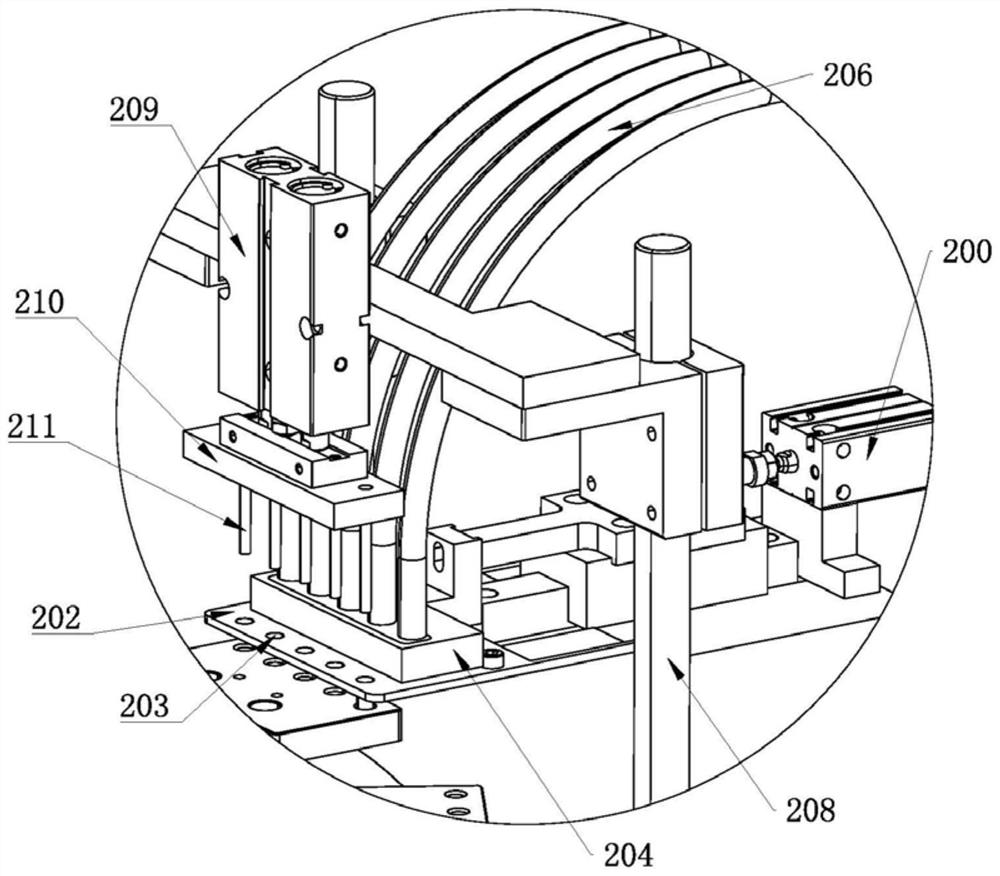

[0066] S1. Copper tube feeding: send the copper tubes to the assembly base in an orderly and continuous manner through vibration, and at the same time make the copper tubes vertically set on the assembly base. After the copper tubes are loaded, the copper tubes are pressed. process;

[0067] S2. Lens feeding: transport and arrange the batches of lenses in an orderly manner, then position the arranged lenses, and then send them to the copper tube by suction. After the lenses are loaded, there will be lens pressure The assembly process, and the lens press-fit is elastic press-fit;

[0068] S3, spring feeding: the spring is sent to the copper tube in an orderly and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com