Mobile operation platform with instrument carrying function

A mobile operation and function technology, applied in motor vehicles, transportation and packaging, single-axis trolleys, etc., can solve the problems of aggravated knee joint wear, increased intra-abdominal pressure, and excessive weight, and achieves simple overall structure, reduced strength, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

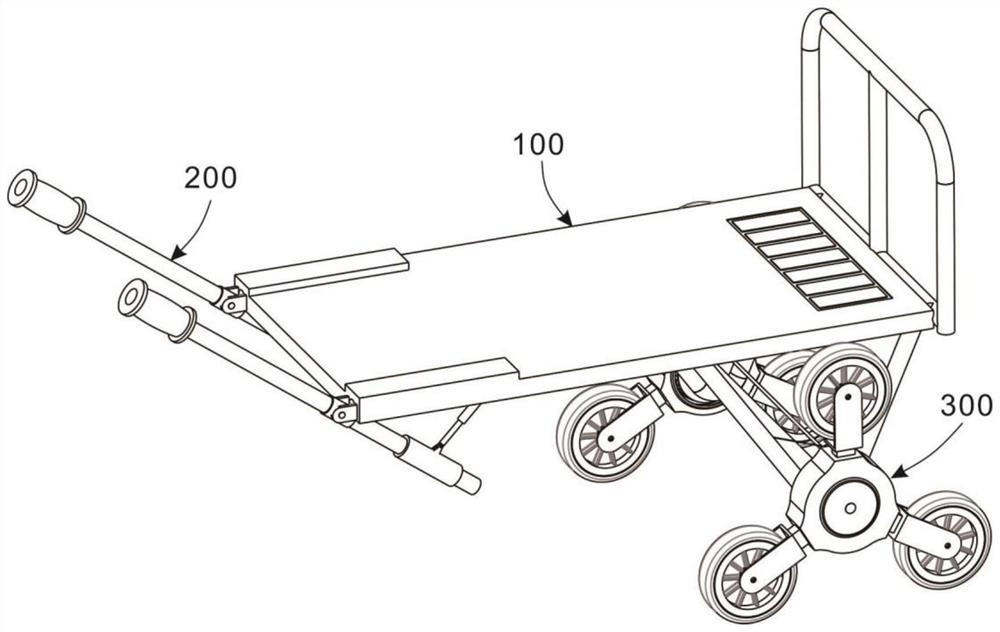

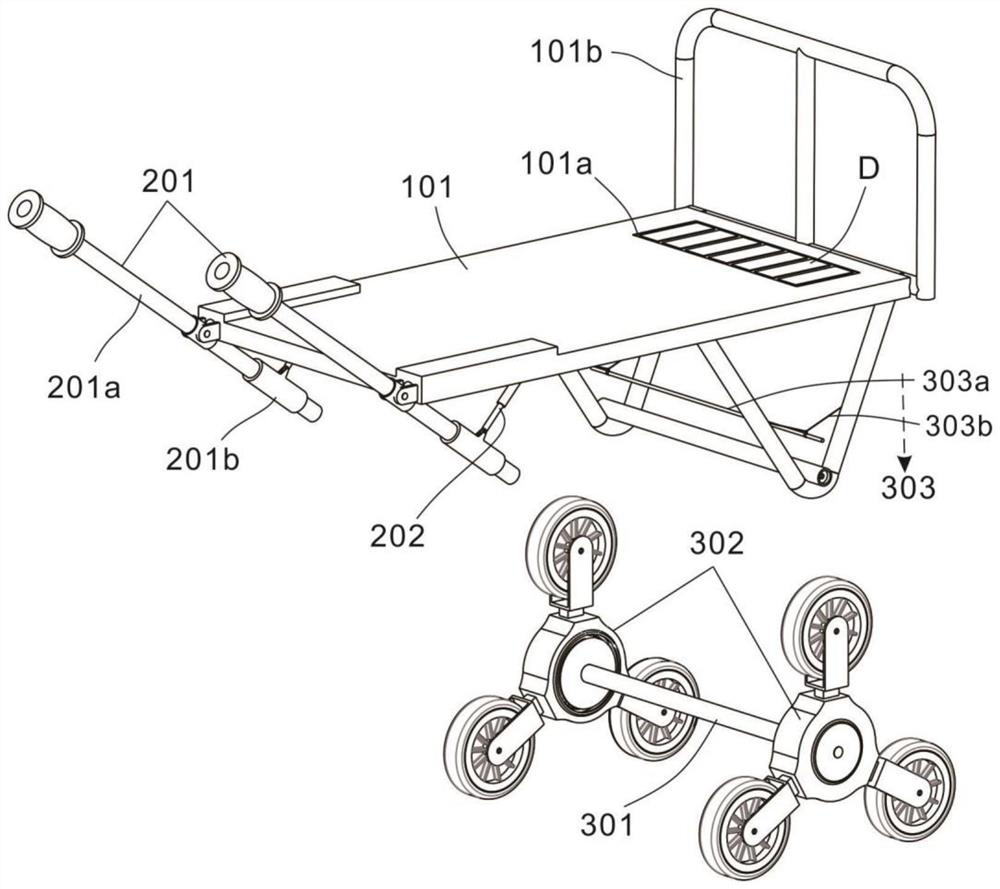

[0036] refer to figure 1 and 2 , which is the first embodiment of the present invention, provides a mobile operating platform with instrument handling function, the mobile operating platform supporting unit 100 , wheel unit 200 and pole unit 300 . Among them, the supporting unit 100 is a plate structure, which is the main part of the transportation device, and is used for the overall placement of the test instrument; and the wheel unit 200 is a multi-wheel structure arranged at the bottom of the supporting unit 100, used for the movement of the device. , and the purpose of the multi-wheel structure is to facilitate the movement of the device on stairs or other uneven ground; the pole unit 300 is used to deform the transport device and use it as an operating platform.

[0037] Specifically, the supporting unit 100 includes a supporting pallet 101 and a supporting frame 102 arranged on the side wall of the supporting pallet 101; The supporting pallets 101 are connected togethe...

Embodiment 2

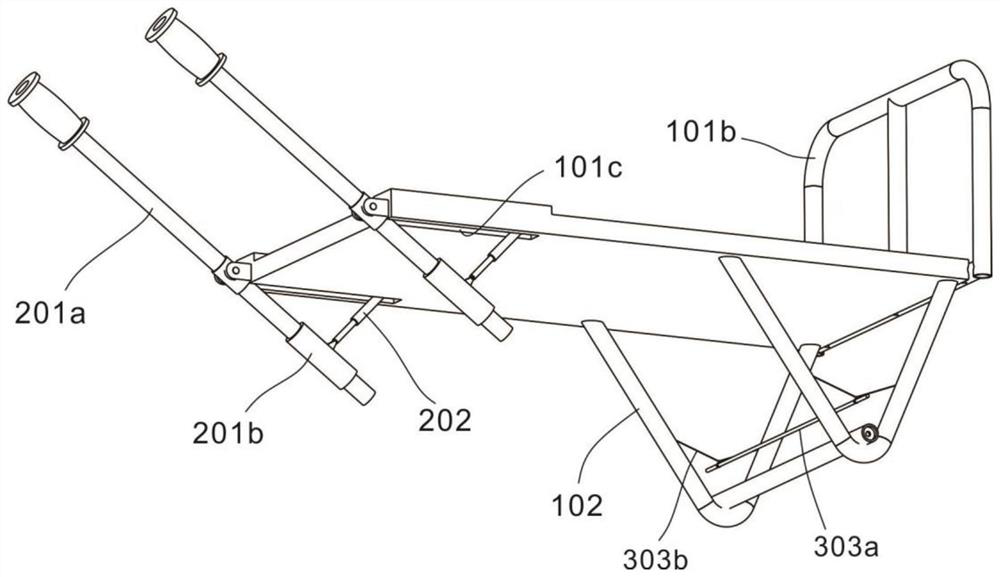

[0041] refer to Figure 2-8 , is the second embodiment of the present invention, and this embodiment is different from the first embodiment in that: a plate groove 101a is opened on the plate surface of the carrying pallet 101, and a power supply D is placed in the plate groove 101a, and the carrying pallet A force receiving plate 101b is provided on one end side wall of 101, and a receiving groove 101c is opened on the other end plate body side wall.

[0042] The top of the support frame 102 is connected to the bottom end of the supporting plate 101 , and the bottom is hinged to the rod body of the connecting shaft 301 .

[0043] The rod assembly 201 includes a rod 201a and a limit sleeve 201b sleeved on the outer wall of the rod 201a. The end of the rod body of the rod 201a, that is, the middle part, is provided with an external thread, and the limit sleeve 201b is provided with an external thread. The inner thread matched with the thread; the end of the support rod 201a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com