Subsection division method for cargo hold area of thin film type LNG ship

A kind of technology of LNG ship and membrane type, which is applied in the direction of warships, etc., can solve the problems that are not conducive to shortening the dock construction cycle, dock construction efficiency, high precision control requirements in the dock loading stage, and difficult to guarantee welding quality, so as to improve the integrity of segmented pre-assembly Integrity and launch integrity, ensure structure centering accuracy and tank capacity construction accuracy, reduce welding workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Below we specifically elaborate in conjunction with accompanying drawing and embodiment:

Embodiment approach

[0041] This embodiment provides a method for segmenting and dividing a typical cross-section of a membrane-type LNG ship cargo hold area. The specific method is as follows:

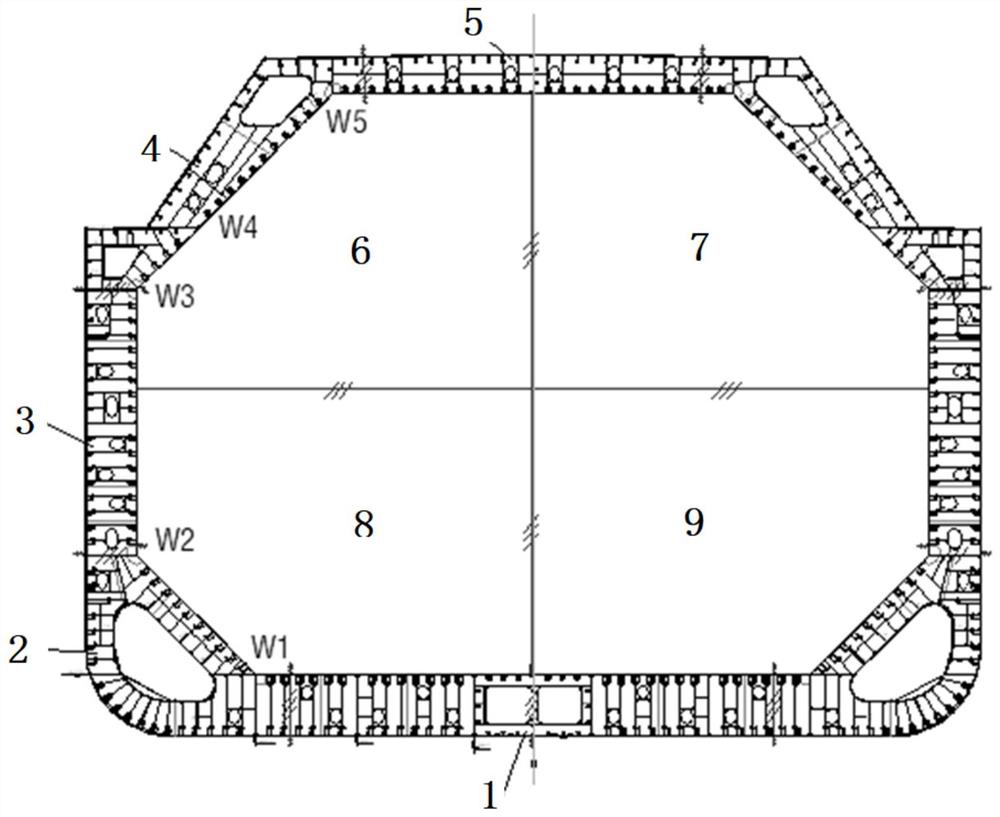

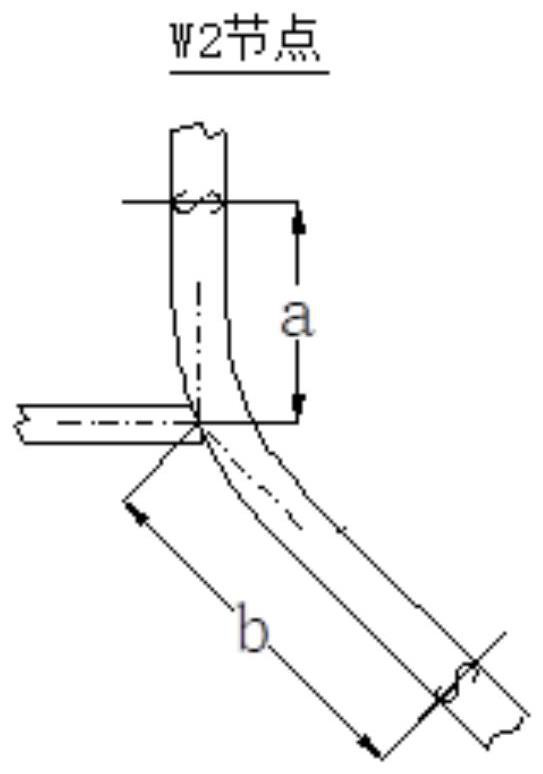

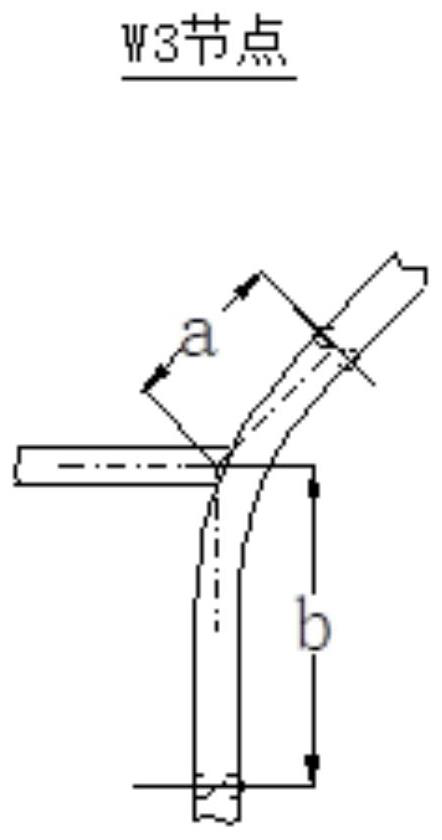

[0042] 1) The entire cross section is divided into 8 typical segment types according to its eight inner hull surfaces, which are bottom segment 1, bilge segment 2, side segment 3, sheer top segment from bottom to both sides and then up. segment 4 and deck segment 5, figure 1 The numbers 6 to 9 in are all sections of the transverse compartment. Among them, the bottom section 1 and the deck section 5 do not contain key nodes, and the other sections contain one or two key nodes, and the design form of the inner shell plate of W2, W3, W5 key nodes shall adopt the arc connection form, Such as Figure 1 to Figure 4 shown.

[0043] 2) Segmentation of the bilge section. W1 and W2 nodes are divided into the bilge section. Since the W1 node is a trihedral welding design, the broken line of the inner bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com