Full-automatic mushroom bag perforating production line

A production line, fully automatic technology, applied in the field of agricultural machinery, can solve the problems of large equipment, limited scope of application, hidden dangers, etc., achieve the effect of high automation, simple and compact structure, and ensure smooth execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

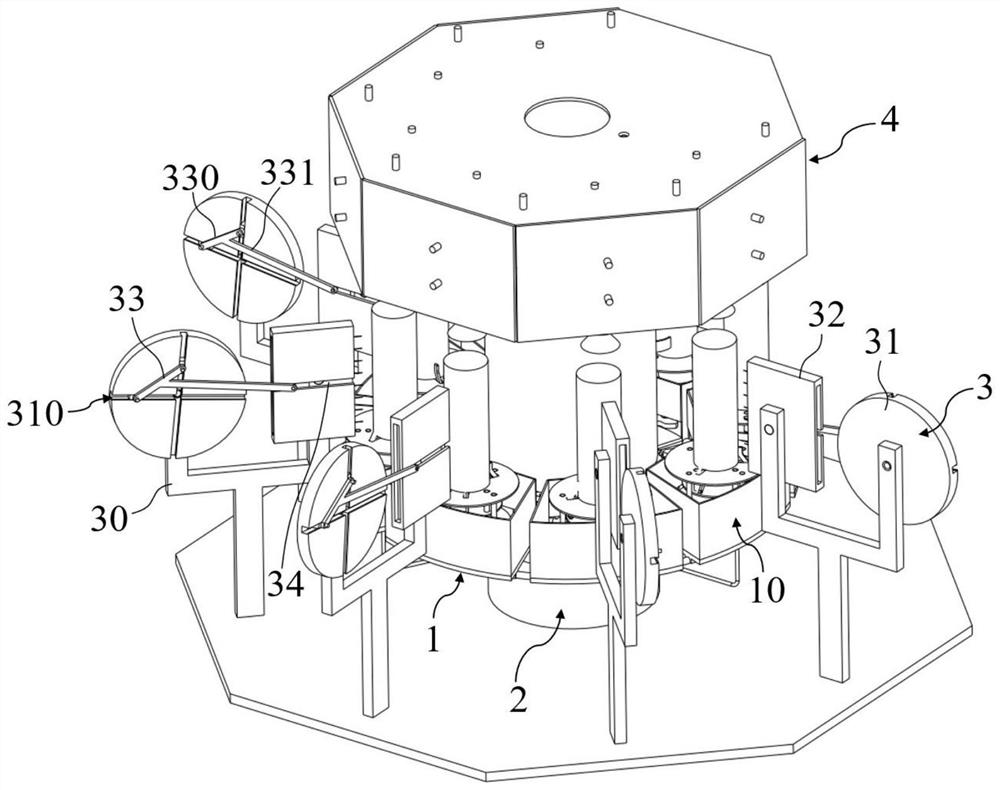

[0081] The full-automatic bacteria bandaging hole production line of the present embodiment includes:

[0082] The mounting plate 1 is arranged horizontally, and the edge of the mounting plate 1 is arranged with several mounting positions 10 along the circumferential direction, and the mounting positions 10 are used for vertically installing the bacteria bag;

[0083] A drive unit 2, which is arranged at the bottom of the installation disk 1, and the drive unit 2 drives the installation disk 1 to rotate around its axis and drives each installation position 10 to rotate;

[0084] The piercing unit 3, which has several, is arranged in a circular shape on the outside of the mounting plate 1, and is used to bind the bacteria on each mounting position 10;

[0085] The feeding unit 5 is arranged on the outside of the installation tray 1, and the bacteria bag is installed on the installation position 10;

[0086] The unloading unit 6 is arranged on the outside of the mounting plate ...

Embodiment 2

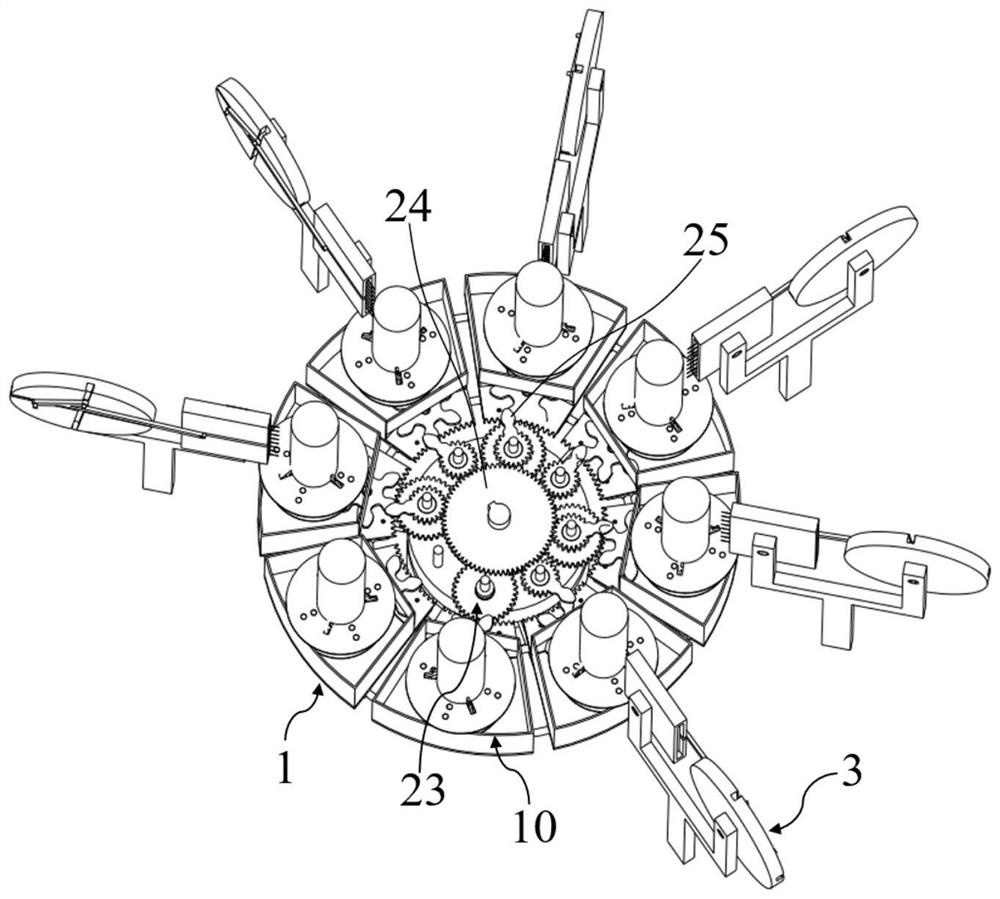

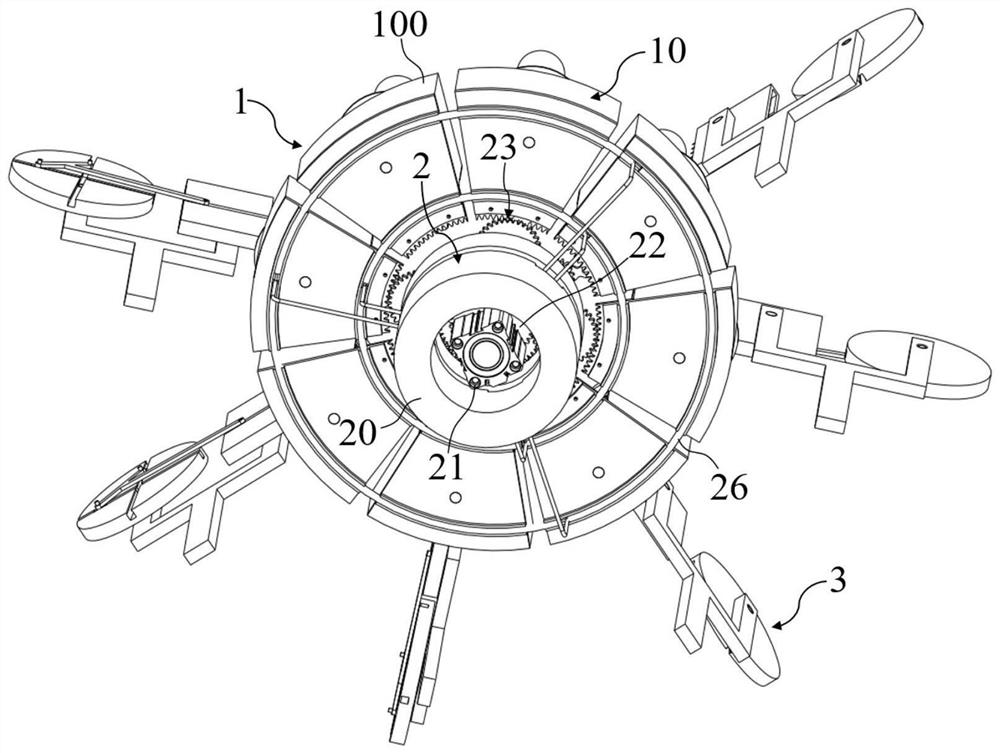

[0091] The fully automatic production line for bacteria dressing holes in this embodiment is further improved on the basis of Embodiment 1, and the drive unit 2 includes:

[0092] The bottom support cylinder 20 is a hollow cylindrical structure with openings at both ends, arranged vertically, and the axis of the bottom support cylinder 20 is collinear with the axis of the mounting plate 1;

[0093] Motor one 21, which is fixedly connected to the hollow interior of the bottom support cylinder 20, the output shaft of the motor one 21 is collinear with the axis of the bottom support cylinder 20;

[0094] Gear one 22, which is placed horizontally directly above the bottom support cylinder 20, said gear one 22 is connected to the output shaft of the motor one 21 through transmission;

[0095] Gear set 23, which includes several gears, several gears are arranged on the edge of the top end surface of bottom support cylinder 20 along the circumferential direction, each gear of said ge...

Embodiment 3

[0102] The fully automatic production line for bacteria dressing holes in this embodiment is further improved on the basis of Embodiment 2, and the installation position 10 includes:

[0103] The installation base plate 100 is fan-shaped and is located at the bottom of the installation position 10. The bottom surface of the installation base plate 100 is formed with an arc-shaped groove matching the annular support guide rail 26. The inner surface of the installation base plate 100 is formed with each gear of the gear set 23. meshing gear teeth;

[0104] Transmission gear set 12, which is placed on the installation base plate 100, and the transmission gear set 12 is in transmission connection with the single-angle gear 25;

[0105] The pressure clamping mechanism 11 is connected to the top of the transmission gear set 12 by transmission, and the pressure clamping mechanism 11 clamps the bacteria bag placed thereon.

[0106] Such as figure 2 , image 3 with Figure 7 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com