Lithium supplement agent and preparation method and application thereof

A lithium supplement and lithium source technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of unstable lithium supplements and inability to effectively provide lithium ions, etc., to increase particle size and improve stability Sex, reduce the effect of residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

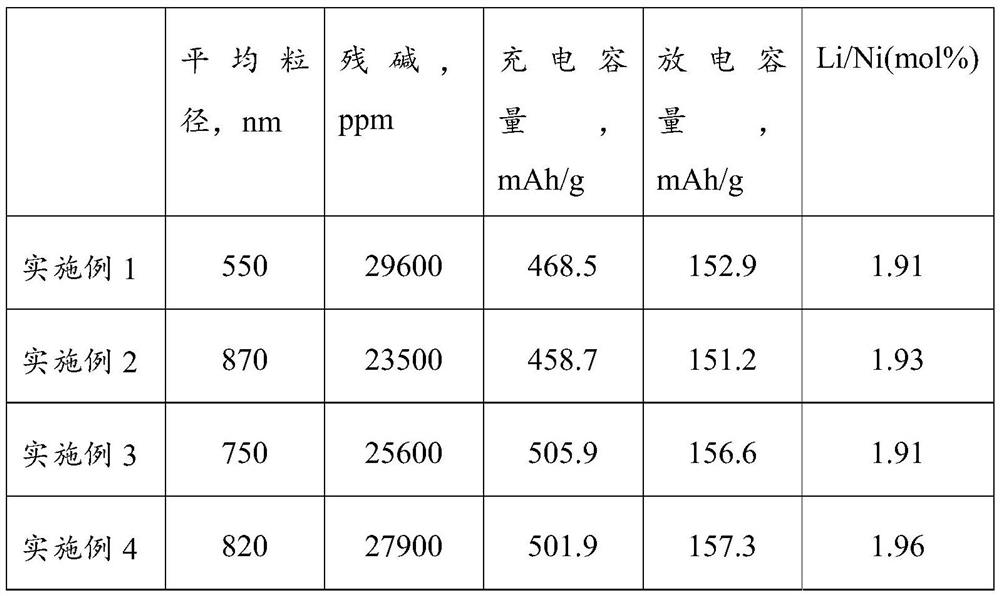

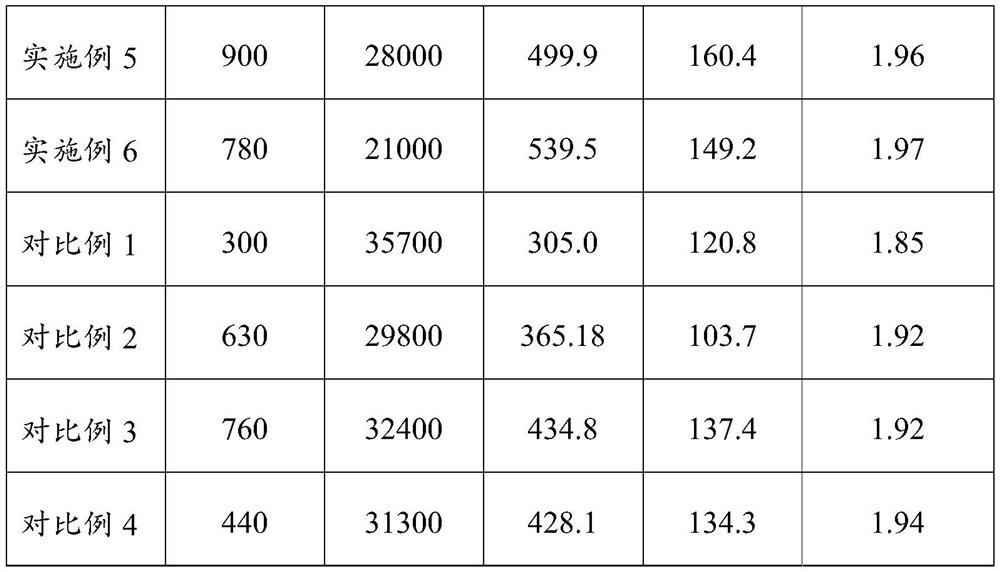

Embodiment 1

[0027] The present embodiment provides a complement to lithium, and specific preparation method:

[0028] (1) in a dry environment, lithium hydroxide and a nickel-containing compound (NiO) in a molar ratio of Li / Ni element is uniformly mixed 2.0;

[0029] (2) The mixed material was placed in a box furnace for calcination, particularly as the calcining operation: temperature increasing rate of 4 ℃ / min heating to 300 ℃, heat 8h, and then, again at a heating rate of 2 ℃ / min of heated to 600 ℃, incubated 12h; calcination of the protective gas is argon flow rate of 10L / min;

[0030] (3) After the sample was naturally cooled after calcination, the complement to give a lithium binder material.

Embodiment 2

[0032] The present embodiment provides a complement to lithium, and specific preparation method:

[0033] (1) in a dry environment, lithium hydroxide and a nickel-containing compound (NiO) in a molar ratio of Li / Ni 2.5 elements mixed;

[0034] (2) The mixed material was placed in a box furnace for calcination, particularly as the calcining operation: a ramp rate of 2 ℃ / min heating to 600 ℃, heat 3h, then again at a temperature rise rate of 4 ℃ / min of temperature was raised to 800 deg.] C, incubated 7H; calcination of the protective gas is argon flow rate of 10L / min;

[0035] (3) After the sample was naturally cooled after calcination, the complement to give a lithium binder material.

Embodiment 3

[0037] The present embodiment provides a complement to lithium, and specific preparation method:

[0038] (1) in a dry environment, lithium hydroxide and a nickel-containing compound (nickel hydroxide) in a molar ratio of Li / Ni element is uniformly mixed 2.1;

[0039](2) The mixed material was placed in a box furnace for calcination, calcining operation is specifically: the heating rate 3 ℃ / min heating to 500 ℃, heat 5h, then, again at a heating rate of 3 ℃ / min of temperature was raised to 700 deg.] C, incubated 10H; calcination of the protective gas is argon flow rate of 10L / min;

[0040] (3) After the sample was naturally cooled after calcination, the complement to give a lithium binder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com