Novel process method for co-processing hazardous waste hw18 through converter

A hw18, co-processing technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems of small growth, less rigid landfill, huge equipment investment, etc., and achieve simple processing technology and operation requirements, The effect of fully utilizing energy and a huge amount of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

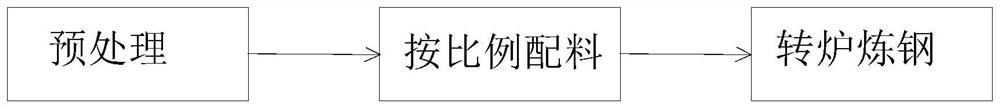

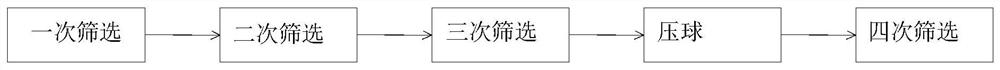

[0035] A new process method for converter co-processing of hazardous waste hw18. There is no new equipment in the converter process, and some equipment is added for pretreatment to make blocks or pellets. The incineration residue hw18 blocks or balls are used as raw materials for smelting in the converter. Since the composition of the bottom slag is close to that of the sinter used as a coolant and slagging agent in the original process, it can replace 50% of the sinter consumption. After the bottom slag reacts with molten iron, scrap steel and other slagging agents through steelmaking, some heavy metals with high oxygen potential in the bottom slag enter the molten steel after reduction and become trace elements in the molten steel, and the remaining bottom slag enters the steel slag system, and the product quality reaches " "Steel slag used in cement" (YB / T022-2008) is used in the technical indicators of steel slag in cement, thus making it a resource and eliminating the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com