Cyclone Powder Activation Coating Machine

A coating machine and powder technology, applied in the coating and other directions, can solve the problems of rough product surface, low coating rate powder, large environmental pollution, etc., to reduce production costs and environmental pollution, improve product quality, phase good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

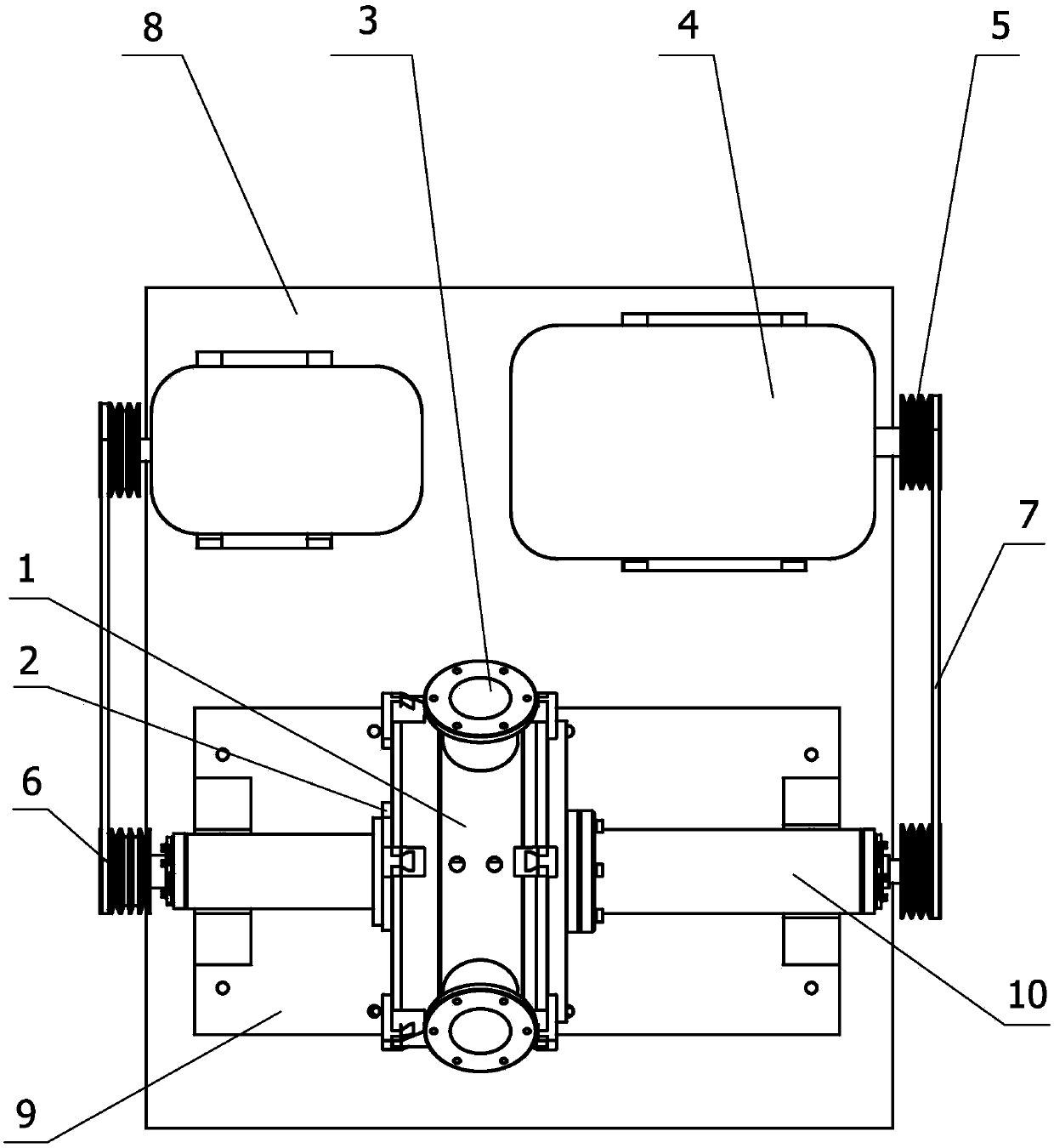

[0013] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0014] The present invention is mainly composed of a powder supply system, an active agent supply system, a coating system, a powder collection system, a dust removal system and an electric control system. The material system, the active agent feed port are connected to the active agent supply system, and the powder discharge port 3 is connected to the powder collection system. The powder collection system is connected to the dust removal system. The electric control system mainly completes the control of the entire set of equipment during operation. , its main actions include start control, synchronization control, flow control, collection program control, powder filtration control and other functions.

[0015] The cladding system host 1 is the key technology of the present invention.

[0016] The main frame 1 of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com