Novel process method for co-processing hazardous waste hw08 by sintering machine

A co-processing, hw08 technology, applied in chemical instruments and methods, solid waste removal, electronic waste recycling, etc., can solve the problems of high process operation requirements, large amount of wastewater, long treatment cycle, etc. Simple requirements, the effect of recycling and full utilization of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

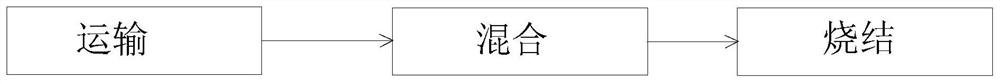

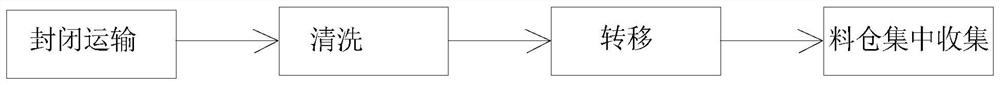

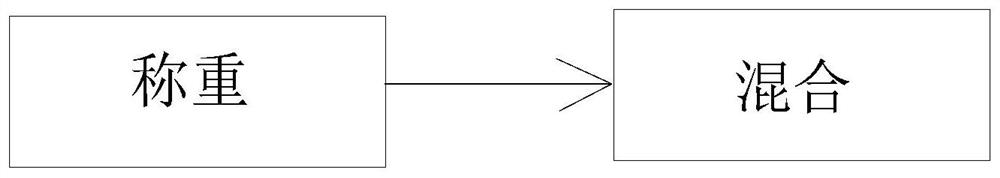

[0038] A new process method for the co-processing of hazardous waste hw08 by sintering machines, which includes the steps of raw material or fuel transportation, batching, mixing, sintering, cooling, screening, and finished product output. Firstly, transport the waste mineral oil and waste hw08 containing mineral oil to the project site in a sealed car, and use the electric single beam crane to transport the waste mineral oil and waste hw08 in bags to the upper part of the newly built 50m3 stainless steel silo, and pass through the upper part of the silo Can breaker or bag breaker, the material enters the silo, and the top cover is closed after the material is loaded. Then, the hw08 in the silo enters the weighing system from the bottom, and is proportioned into the sintering mixture. After mixing, it enters the sintering mixture silo, and then enters the sintering machine for sintering, and finally sinters into a sintered ore product. The process method can fully utilize hwo8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com