Method for preparing Q235B casting blank from high-sulfur low-manganese vanadium-titanium molten iron

A technology of Q235B and molten iron, applied in the field of iron and steel smelting and casting, can solve problems such as surface bulging, center penetrating cracks, surface corrosion spots, etc., achieve the effect of no center penetrating cracks, reduce depth, and increase shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: The S content in the hot metal after desulfurization is designed to be <0.025%, and the actual measured value is S=0.023%.

Embodiment 2

[0036] Embodiment 2: The S content in the hot metal after design desulfurization is <0.020%, more preferably S<0.015%, and the actual measured value is S=0.017%.

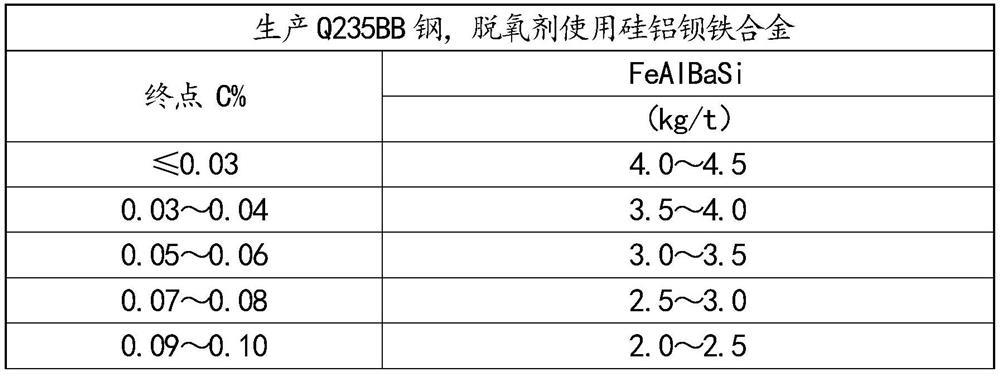

[0037] 3. Converter steelmaking

[0038] Oxygen top-blown converter (150t) is used for steelmaking, and the specific operation process is as follows:

[0039] (1) Tapping and slag dumping in the upper furnace, check the furnace lining and tilting equipment, etc., and carry out necessary repairs and repairs;

[0040] (2) Tilt the furnace, add scrap steel, add molten iron (semi-steel), shake the furnace body;

[0041] (3) The lowering gun is turned on and blown, and the first batch of slag is added at the same time, and the amount of addition is equivalent to 2 / 3 of the total slag of the whole furnace;

[0042] (4) After 3 to 5 minutes, add the second batch of slag to continue blowing;

[0043] (5) Invert the furnace, measure temperature, take samples, and determine the blowing time or tapping;

[0044](6) Tapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com