Method for preparing hollow high voltage nickel manganese acid lithium anode material

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the field of preparation of high voltage lithium nickel manganese oxide positive electrode materials with hollow morphology, can solve the problems of structural stress and volume change, complex preparation process, and uneven materials, and achieve reduction Effect of specific surface area, improvement of cycle performance, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment 1: In this embodiment, the lithium nickel manganate material is prepared according to the following steps:

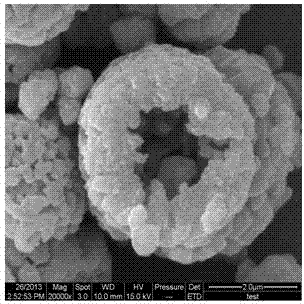

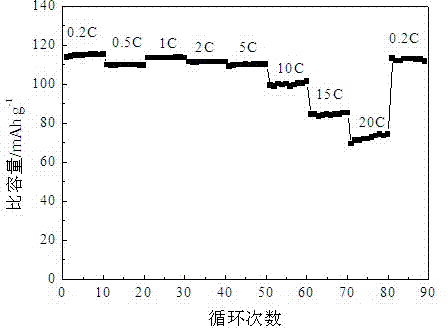

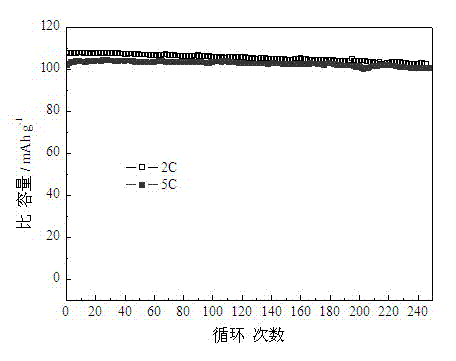

[0027] Prepare 1L 0.04 mol / L manganese sulfate solution, add 100ml absolute ethanol to the solution and stir evenly; then slowly drop 1L 0.4mol / L ammonium bicarbonate solution into the solution while stirring, filter and wash to obtain precipitated carbonic acid Manganese; Put manganese carbonate in a muffle furnace and calcinate at 350℃ for 4 hours to obtain a mixture; put the mixture into 0.1 mol / L hydrochloric acid and stir for 4 hours, filter and wash to obtain manganese dioxide; molar ratio Li:Ni :Mn=1.05:0.5:1.5 Weigh the lithium hydroxide, nickel nitrate and the manganese dioxide obtained in the previous step, and mix them by ball milling for 2 h to obtain the precursor; put the precursor in the air atmosphere of the muffle furnace, and preheat it at 400℃ It is calcined for 6 hours, and then heated to 800°C for 14 hours to obtain lithium n...

specific Embodiment approach 2

[0029] Specific implementation manner 2: In this implementation manner, a lithium nickel manganate material is prepared according to the following steps:

[0030] Prepare 1L 0.16 mol / L manganese sulfate solution, add 200ml of absolute ethanol to the solution, and stir evenly; then slowly add 1L 0.8mol / L ammonium bicarbonate solution to the solution while stirring, filter and wash to obtain precipitated carbonic acid Manganese; Put manganese carbonate in a muffle furnace and calcinate at 300°C for 3 hours to obtain a mixture; put the mixture in 0.2mol / L hydrochloric acid and stir for 2 hours, filter and wash to obtain manganese dioxide; molar ratio LiOH:C 2 H 3 O 2 Li: C 4 H 6 NiO 4 :MnO 2 =0.5:0.5:0.5:1.5 Weigh the lithium hydroxide, lithium acetate, nickel acetate and the manganese dioxide obtained in the previous step, ball mill and mix for 3 h to obtain the precursor; put the precursor in the air atmosphere of the muffle furnace at 500 Pre-calcined at ℃ for 3 h, then heated to ...

specific Embodiment approach 3

[0032] Specific embodiment 3: In this embodiment, the lithium nickel manganate material is prepared according to the following steps:

[0033] Prepare 1L 0.05 mol / L manganese sulfate solution, add 1L 4mol / L ammonium sulfate to the solution and stir evenly; then slowly drop 1L 0.45mol / L ammonium bicarbonate solution into the solution while stirring, and filter and wash to obtain Precipitate manganese carbonate; put manganese carbonate in a muffle furnace and calcinate at 300°C for 5 hours to obtain a mixture; put the mixture into 0.2mol / L sulfuric acid and stir for 2 hours, filter and wash to obtain manganese dioxide; mole ratio LiOH : Ni(NO 3 ) 2 : C 4 H 6 NiO 4 :MnO 2 =1:0.25:0.25:1.5 Weigh lithium hydroxide, nickel nitrate, nickel acetate and the manganese dioxide obtained in the previous step, and disperse them in 20ml of ethanol. Stir at room temperature to evaporate the ethanol to obtain a precursor; put the precursor into In the air atmosphere of the muffle furnace, pre-fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com