An assembled longitudinal beam, an assembled support without buttresses, a system and a design method thereof

A prefabricated, pier-free technology, applied in bridge erection/assembly, bridge construction, design optimization/simulation, etc., can solve the problems of material waste, applicability, cumbersome design, and poor versatility of pier-free supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

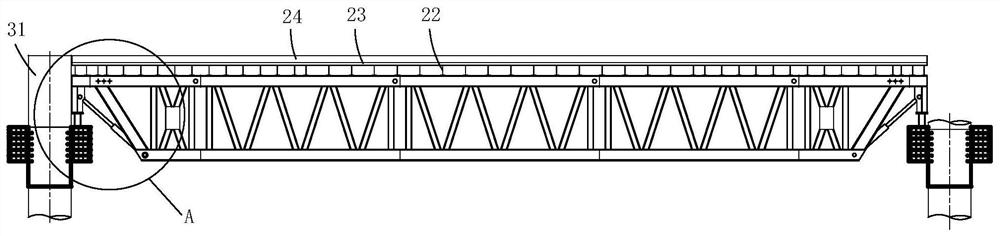

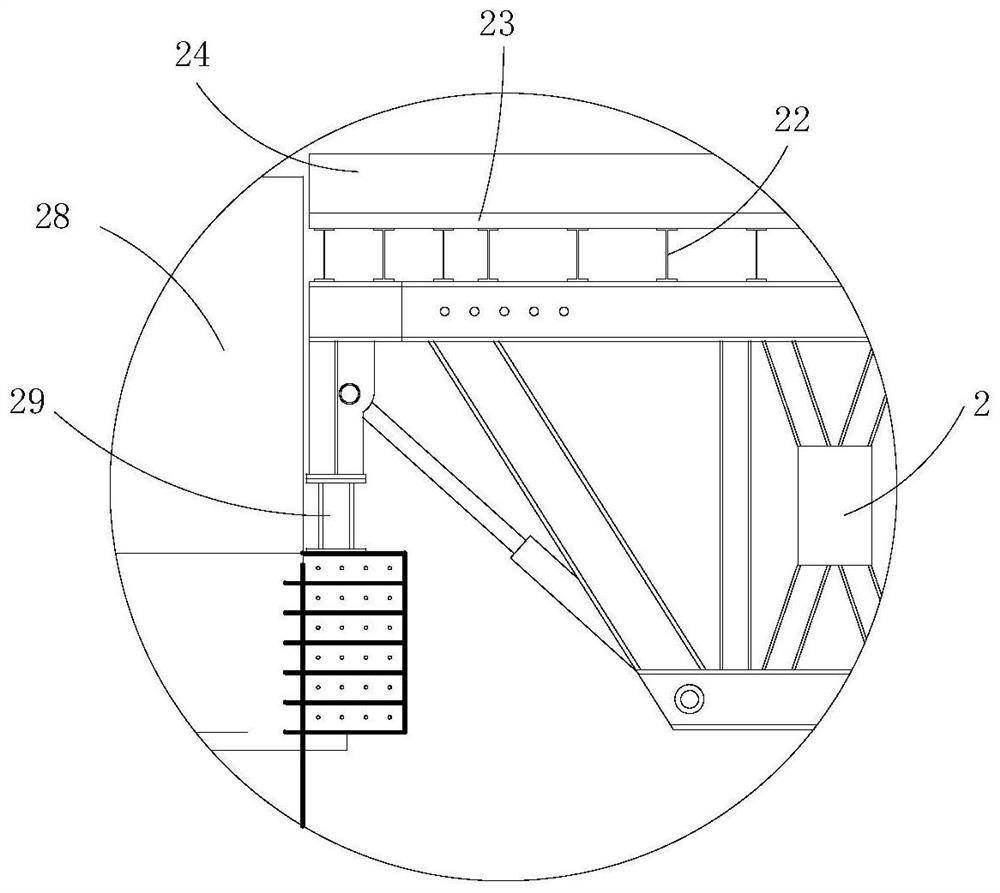

[0129] like Figure 1-10As shown, a prefabricated longitudinal beam described in this embodiment includes a standard truss section 1, two ends of the standard truss section 1 are detachably connected with an adjustable section 2, and the length of the adjustable section 2 can be adjusted , the total longitudinal length range after the standard truss segment 1 and the adjustable segments 2 at both ends are matched can satisfy at least two span lengths between the first threshold value and the second threshold value.

[0130] In the test, it was found that the stability of the truss itself cannot be guaranteed if the span exceeds 30m, and the span is less than 20m, and the advantages of the present application over the Bailey beam are not obvious.

[0131] It needs to be explained here: the longitudinal direction in the total longitudinal length after the standard truss section 1 and the adjustable sections 2 at both ends are matched are as follows: Figure 24 The length direct...

Embodiment 2

[0156] like Figure 10 As shown, the prefabricated longitudinal beam described in this embodiment is different from Embodiment 1 in that it is easy to distinguish between different types of standard truss segment units based on blanking, transportation, manufacturing, and at the same time, it is convenient for combination considerations. The total longitudinal length range after one or more of the standard truss segment units and the two adjustable segments 2 are matched can satisfy all integer meters between the first threshold value and the second threshold value.

[0157] Specifically, the length of the third standard truss segment unit (3), the length of the second standard truss segment unit (4) and the first standard truss segment unit (5) are arranged in an arithmetic progression.

[0158] More specifically, the longitudinal length of the first standard truss segment unit 5 is 9m; the longitudinal length of the second standard truss segment unit 4 is 7m; the longitudina...

Embodiment 3

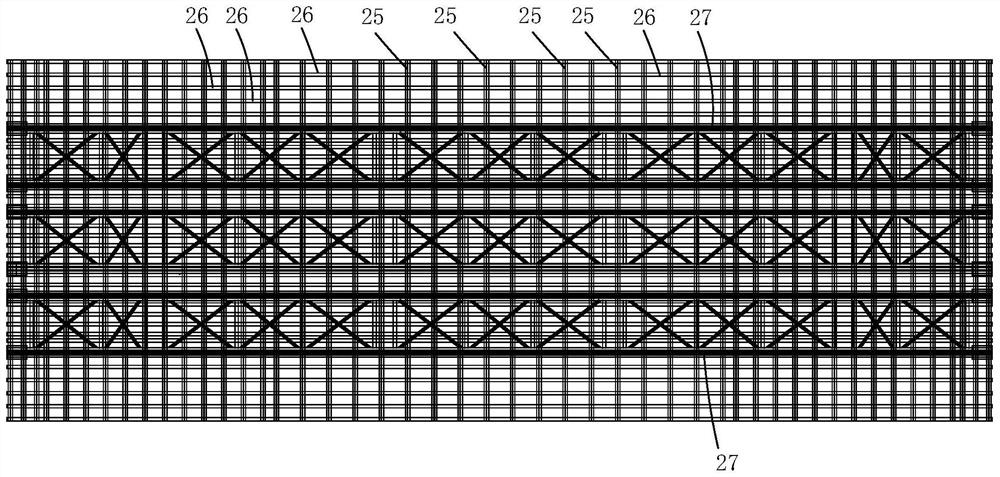

[0166] like Figure 10 As shown, a prefabricated longitudinal beam described in this embodiment is different from Embodiment 1 or 2 in that the connecting truss 6 includes side pieces 12 that are vertically spaced apart and connected to each other. 12 includes two straight web rods 18 arranged at intervals, and an X-shaped oblique web rod 19 is provided between the two straight web rods 18, wherein,

[0167] One end of the straight web rod 18 is connected with the upper chord rod 14, and the other end of the straight web rod 18 is connected with the lower chord rod 15;

[0168] One end of the X-shaped oblique web bar 19 is connected to the upper chord 14 , and the other end of the X-shaped oblique web bar 19 is connected to the lower chord 15 .

[0169] like Figure 8 and 32 , 33, in the test, when the boundary conditions of the model and the load conditions are consistent, only the form of the adjustable section 2 web rod is changed. The adjustable section 2 web rod of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com