Seamless steel tube continuous rolling process intelligent prediction system and method based on Matlab

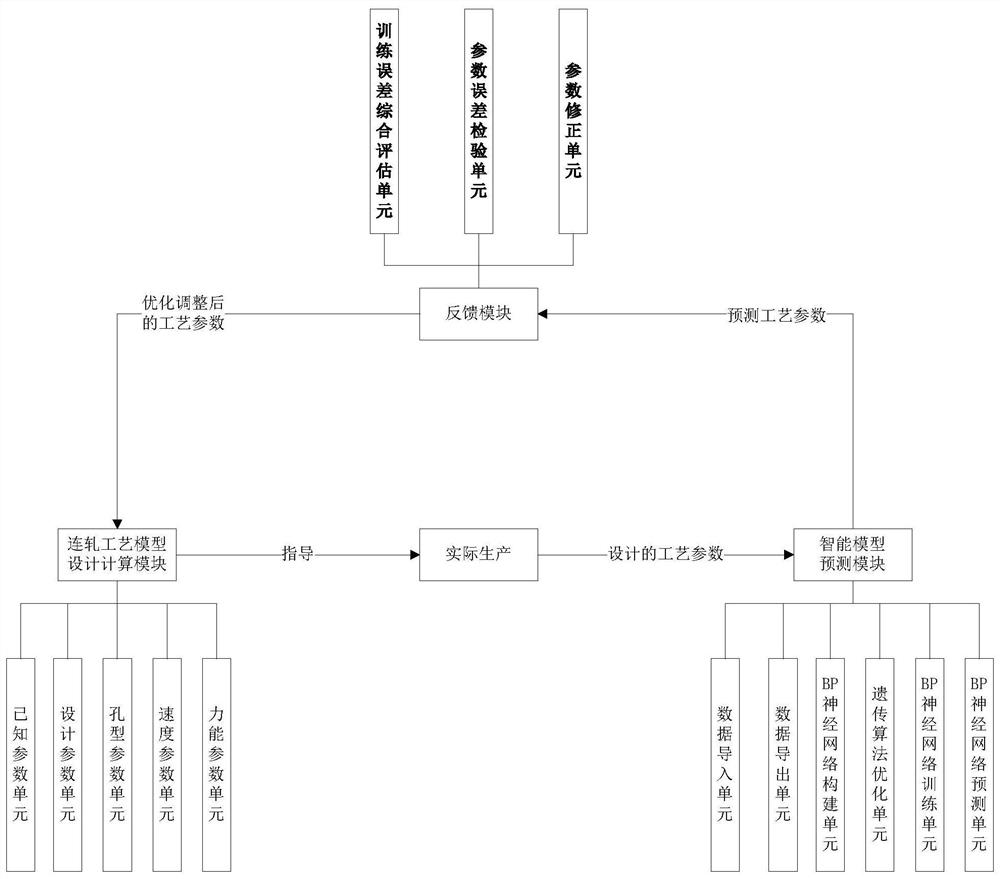

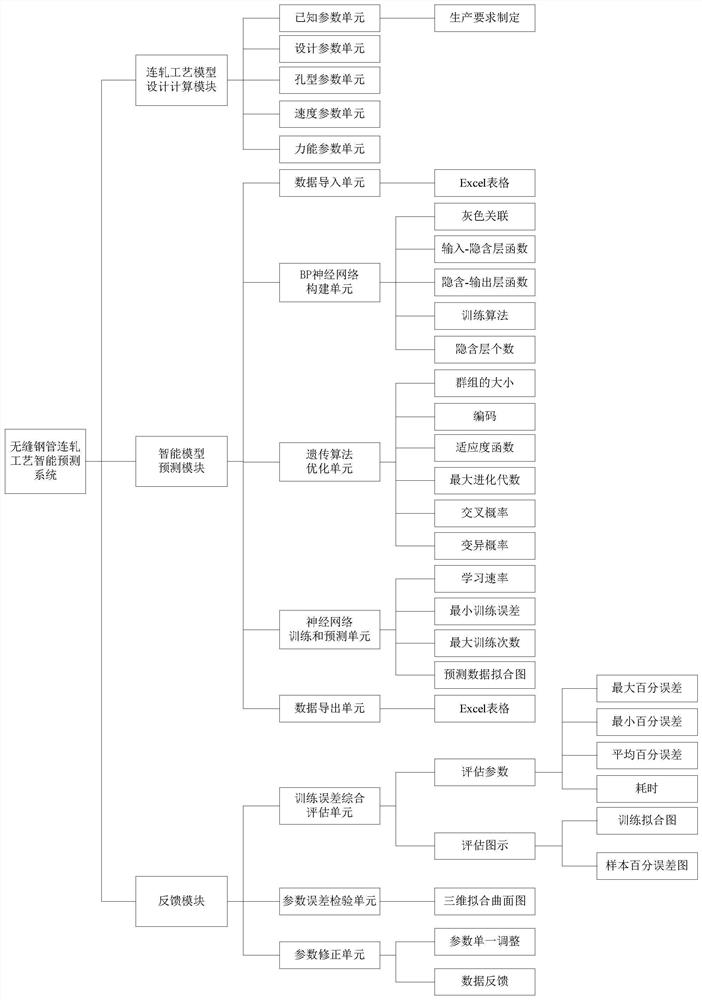

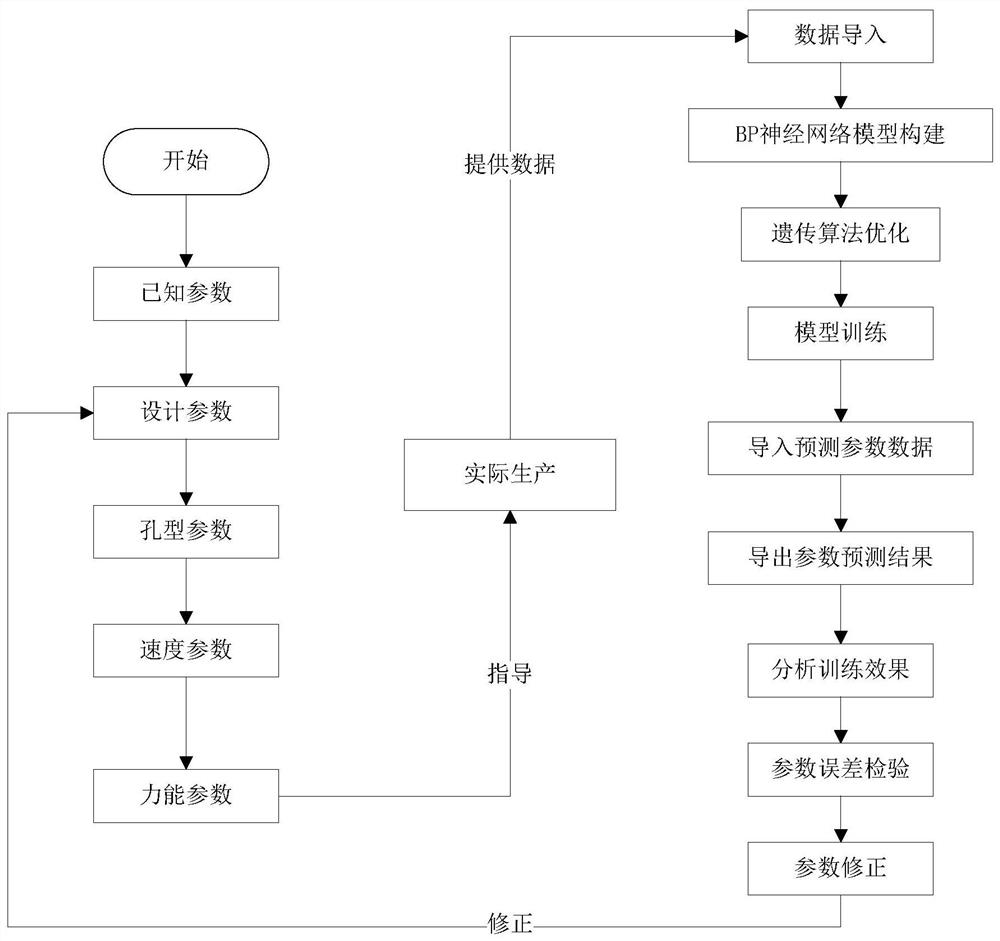

A seamless steel pipe, intelligent prediction technology, applied in the direction of neural learning method, biological neural network model, design optimization/simulation, etc., can solve the problems of seamless steel pipe continuous rolling process modeling and quality cannot be accurately and intelligently predicted, and achieve superior The effect of data image fitting and analysis capabilities, flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071]Based on the aforementioned background technology, the current continuous rolling process of seamless steel pipes has the defect that the modeling and quality cannot be accurately and intelligently predicted.

[0072] However, with the development of artificial intelligence, the learning model driven by big data as the core has been applied to various industries. Among them, the artificial neural network is developed on the basis of the "synapse hypothesis". It is a highly nonlinear intelligent information processing system with adaptive learning characteristics. A neural network can flexibly and accurately solve problems of multivariable nonlinear systems by using a large amount of raw data.

[0073] Moreover, Matlab software has its own artificial intelligence neural network toolbox nntool, which can realize the establishment, training and prediction of neural network prediction models combined with Matlab programming, and can also write programs by itself to achieve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com