TFT-LCD-based defect authenticity detection judgment method and system

A determination method and defect technology, applied in manufacturing computing systems, character and pattern recognition, image data processing, etc., can solve problems such as long matching time, congenital deficiencies, defect image collection, etc., to improve speed and accuracy, and reduce differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Such as figure 1 As shown, the object of the present invention is to realize the true and false judgment of TFT-LCD defects, and the calculation process is as follows:

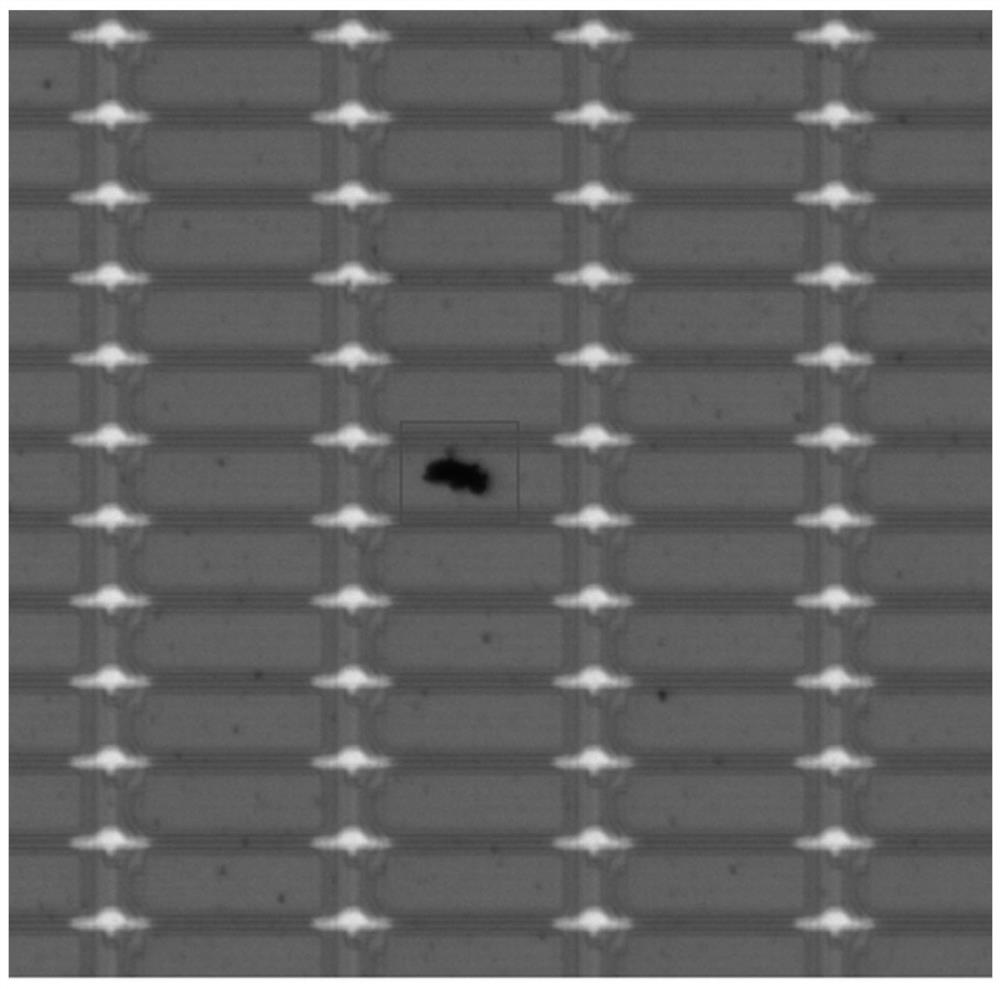

[0057] 1. Obtain the location information of the detected defect, such as figure 2 :

[0058] When detecting a defect, record the position information of the defect to obtain the position of the defect.

[0059] Specifically, the defect is detected by a detection algorithm and the location information of the defect is recorded. The detection algorithm can detect defect images and coordinate information thereof according to various defect detection algorithms in the prior art. The present invention does not limit the algorithm for detecting defects, as long as the defects can be detected.

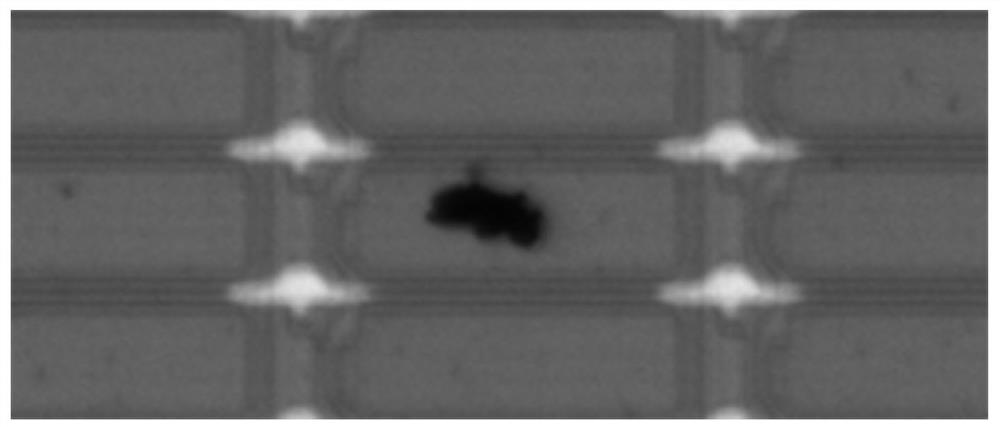

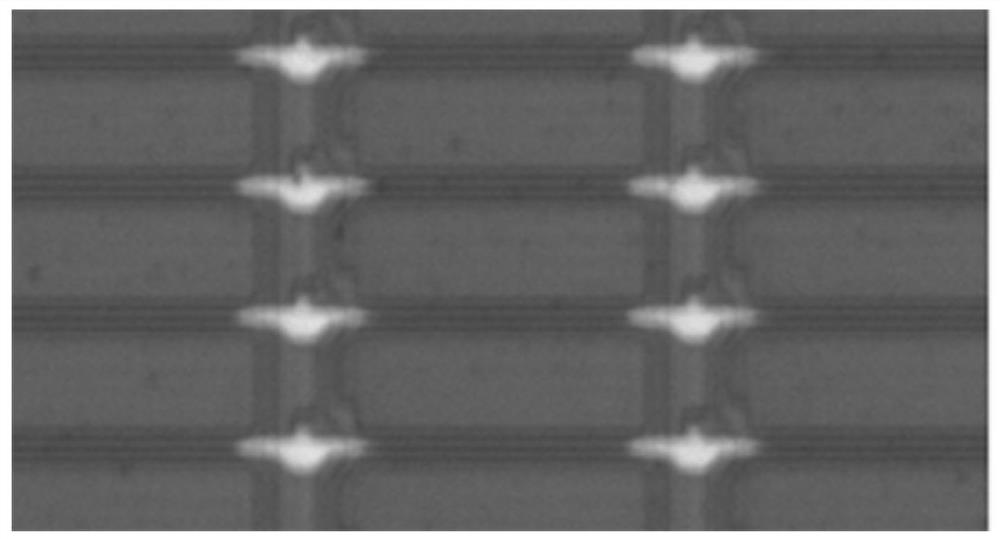

[0060] 2. Obtain defect images, such as image 3 :

[0061] Taking the central position of the defect as the center, the width and height of the minimum repeating unit of the TFT-LCD panel are the basic image s...

Embodiment 2

[0075] This embodiment provides a system for judging the authenticity of defects based on TFT-LCD, such as Figure 16 shown, including:

[0076] Defect location module 100, configured to acquire defect location information;

[0077] A reference image module 200, configured to obtain a defect image and two reference images according to defect location information;

[0078] Aligning the image module 300, for performing local image alignment with the defect image and two reference images, to obtain two alignment images;

[0079] An enhanced filtering module 400, configured to perform image enhancement and Gaussian bilateral filtering on the two alignment images and the defect image;

[0080] The authenticity determination module 500 is used to calculate the absolute value of the difference between the filtered defect image and each filtered alignment image, and compare it with the set threshold to obtain two defect result maps, so as to determine the authenticity of the defect....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com