Oil-control moisturizing hair composition containing double proteins

A composition and dual-protein technology, applied in the field of toiletries, can solve problems such as easy oil production, achieve smooth hair, improve oil control effect, and scalp oil control and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

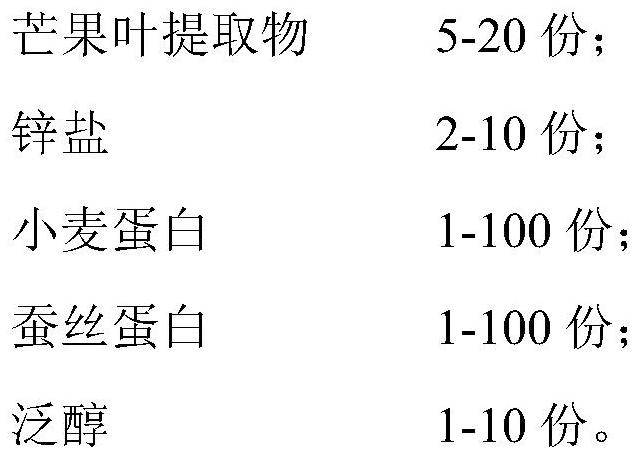

Method used

Image

Examples

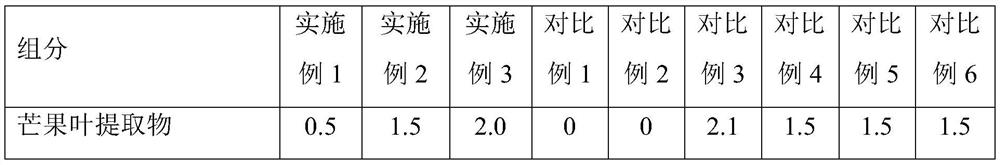

Embodiment 1

[0046] This embodiment provides a kind of oil control moisturizing shampoo, its composition and mass percentage content are:

[0047] Mango Leaf Extract 1.25%, Zinc Lactate 1.0%, Zinc Gluconate 0.1%, Wheat Protein 5.0%, Silk Protein 5.0%, D-Panthenol 0.5%, Sodium Laureth Sulfate 11.5%, Lauramidopropyl Betaine 4%, Cocamidopropyl Hydroxysultaine 1.5%, Decyl Glucoside 0.8%, Polyquaternium-10 0.2%, Polyquaternium-22 0.3%, Disodium EDTA 0.04%, Coconut Oleic acid monoethanolamide 0.8%, sodium chloride 0.4%, preservative 0.065%, essence 0.4%, citric acid 0.1% and the balance water.

[0048] The preparation process of oil control moisturizing shampoo is as follows:

[0049] Add the selected surfactants, disodium edetate, and monoethanolamide cocoate in deionized water in sequence, and heat up to 65°C while stirring; add polyquaternium-10 and polyquaternium-22 to prepare In the obtained mixture, stir to heat up to 90°C, then stir to cool down to 60°C; add mango leaf extract, zinc lac...

Embodiment 2

[0051] This embodiment provides a kind of oil control moisturizing shampoo, its composition and mass percentage content are:

[0052] Mango Leaf Extract 0.5%, Zinc Lactate 0.5%, Zinc Gluconate 0.5%, Wheat Protein 0.1%, Silk Protein 10.0%, D-Panthenol 1.0%, Sodium Laureth Sulfate 12%, Lauramidopropyl Betaine 4.5%, Cocamidopropyl Hydroxysultaine 2.0%, Decyl Glucoside 1%, Polyquaternium-10 0.25%, Polyquaternium-22 0.35%, Disodium EDTA 0.05%, Coconut Oleic acid monoethanolamide 1%, sodium chloride 0.3%, preservative 0.07%, essence 0.45%, citric acid 0.15% and the balance water.

[0053] The preparation process of oil control moisturizing shampoo is as follows:

[0054] Add selected surfactants, disodium ethylenediaminetetraacetate and cocoic acid monoethanolamide in deionized water in sequence, and heat up to 70°C while stirring; add polyquaternium-10 and polyquaternium-22 to prepare In the obtained mixture, stir to heat up to 90°C, then stir to cool down to 60°C; add mango leaf...

Embodiment 3

[0056] This embodiment provides a kind of oil control moisturizing shampoo, its composition and mass percentage content are:

[0057] Mango Leaf Extract 2.0%, Zinc Lactate 0.1%, Zinc Gluconate 1.0%, Wheat Protein 10.0%, Silk Protein 0.1%, D-Panthenol 0.1%, Sodium Laureth Sulfate 13%, Lauramidopropyl Betaine 5.5%, Cocamidopropyl Hydroxysultaine 2.5%, Decyl Glucoside 1.5%, Polyquaternium-10 0.3%, Polyquaternium-22 0.4%, Disodium EDTA 0.06%, Coconut Oleic acid monoethanolamide 1.2%, sodium chloride 0.2%, preservative 0.075%, essence 0.5%, citric acid 0.18% and the balance water.

[0058] The preparation process of oil control moisturizing shampoo is as follows:

[0059] Add selected surfactants, disodium ethylenediaminetetraacetic acid, and cocoic acid monoethanolamide in deionized water in sequence, and heat up to 75°C while stirring; add polyquaternium-10 and polyquaternium-22 to prepare In the obtained mixture, stir to heat up to 90°C, then stir to cool down to 60°C; add man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com