Food package sealing performance detection system

A sealing detection and food packaging technology, which is applied in the field of sealing detection equipment, can solve the problems of low detection efficiency, low work efficiency, complex detection equipment system, etc., and achieve high accuracy of detection results, accelerated drying speed, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

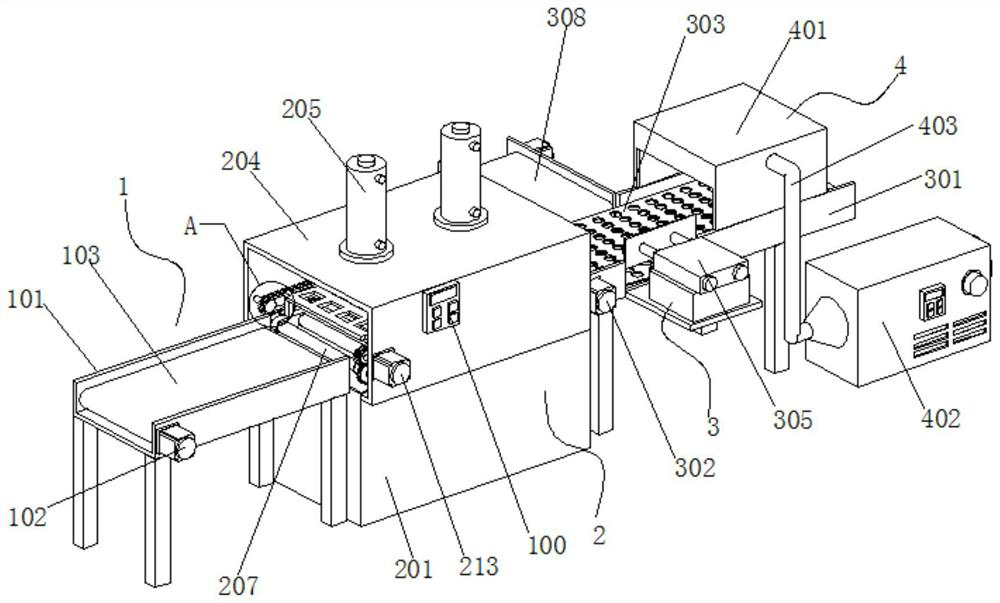

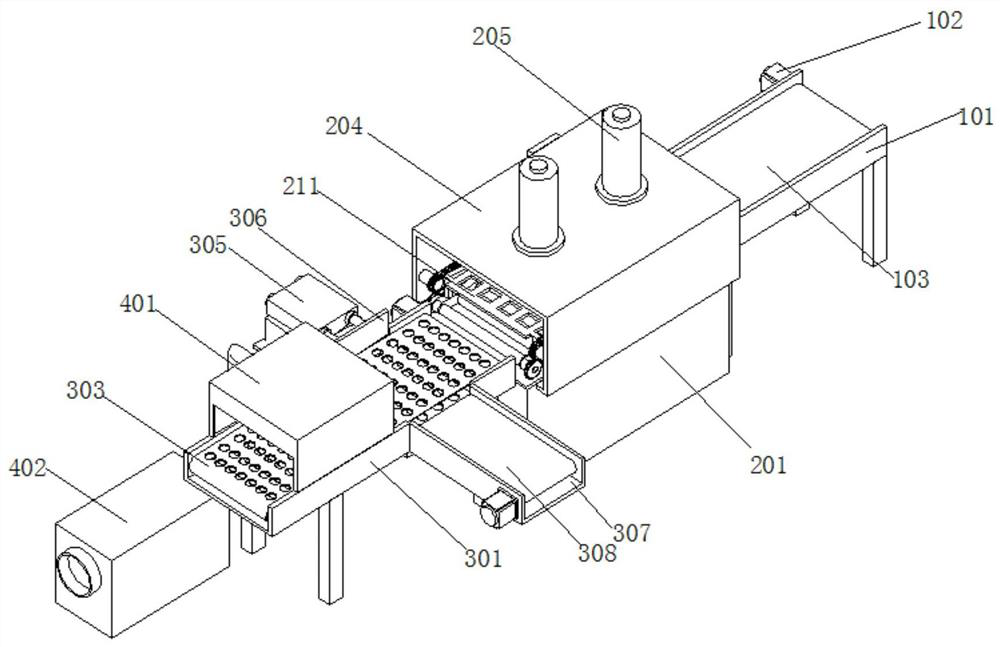

[0039] This embodiment 1 introduces a food packaging airtightness detection system, refer to the attached figure 1 And attached figure 2 , which includes a food packaging bag feeding device 1, a sealing detection mechanism 2, a sorting mechanism 3 and a draining and drying device 4.

[0040] Wherein, food packaging bag feeding device 1 comprises the first U-shaped transmission frame 101, the left and right ends of the first U-shaped transmission frame 101 are provided with belt transmission rollers (not shown in the figure), the first U-shaped transmission frame The front side of 101 is provided with a first servo motor 102, the output shaft of the first servo motor 102 extends into the first U-shaped transmission frame 101 and is connected with one of the belt transmission rollers, and the second belt transmission roller is arranged between the two belt transmission rollers. A conveyor belt 103 .

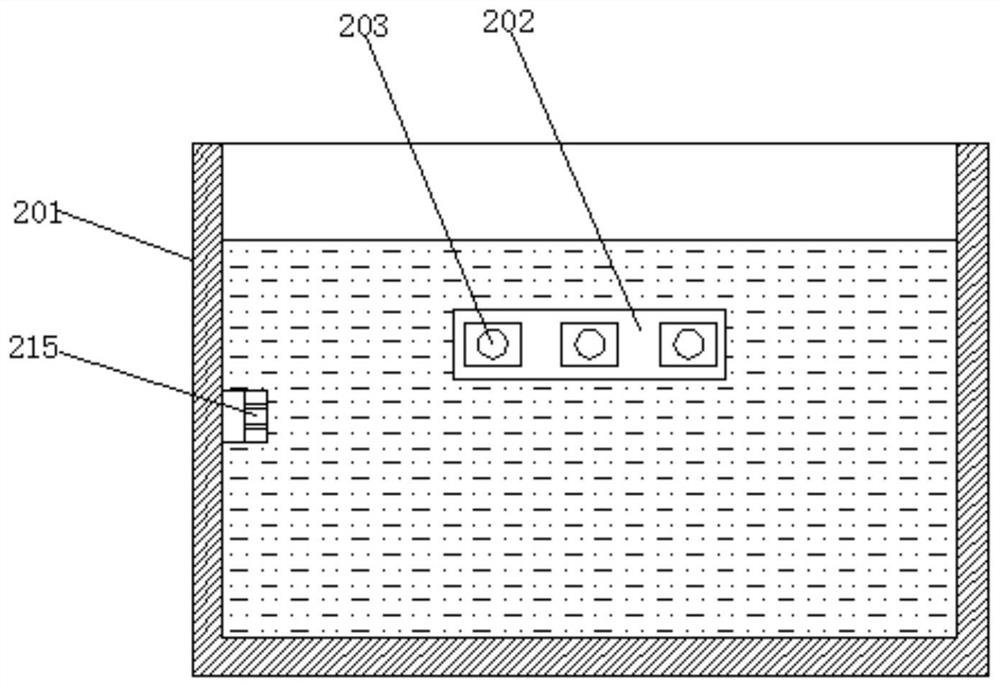

[0041] Reference attached image 3 , the leak detection mechanism 2 inclu...

Embodiment 2

[0046] Example 2 introduces a food packaging airtightness detection system improved on the basis of Example 1. Its similarities with Example 1 will not be described again. For the differences, refer to the attached Figure 9 .

[0047] First of all, the present embodiment 2 is also connected with several horizontal hot-air branch pipes 405 at intervals on the hot-air pipe 403 in the drying box 401, and the lower surface of each hot-air branch pipe 405 is provided with a plurality of hot-air outlets 404, and its hot-air branch pipe 405 The above-mentioned design can make the hot air discharged from the hot air pipe 403 blow to the soaked packaging bag more comprehensively, thereby speeding up the drying process.

[0048] In addition, the present embodiment 2 is also provided with a wind power adjustment switch 4021 and a temperature adjustment knob 4022 on the front side of the hot air blower 402, the wind power of the hot air blower can be adjusted by the wind power adjustment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com