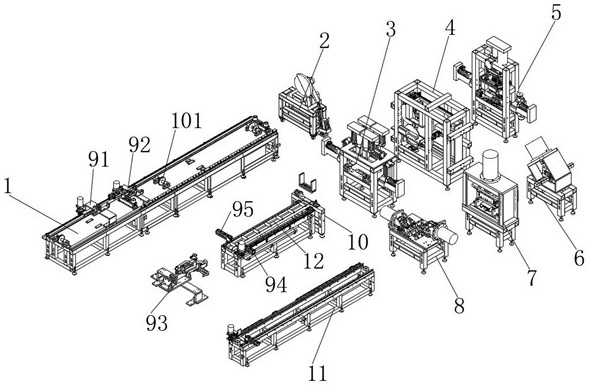

Combinable multifunctional profile processing machine

A kind of processing machinery and multi-functional technology, applied in the direction of metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inability to realize standardized large-scale manufacturing, high machine cost, poor variability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

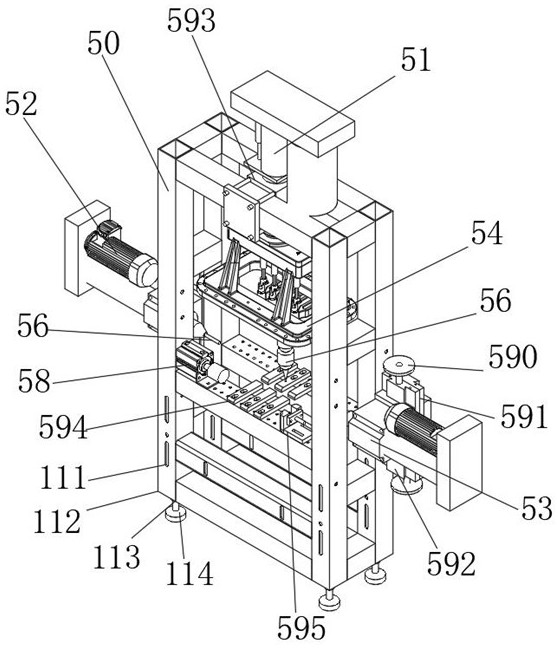

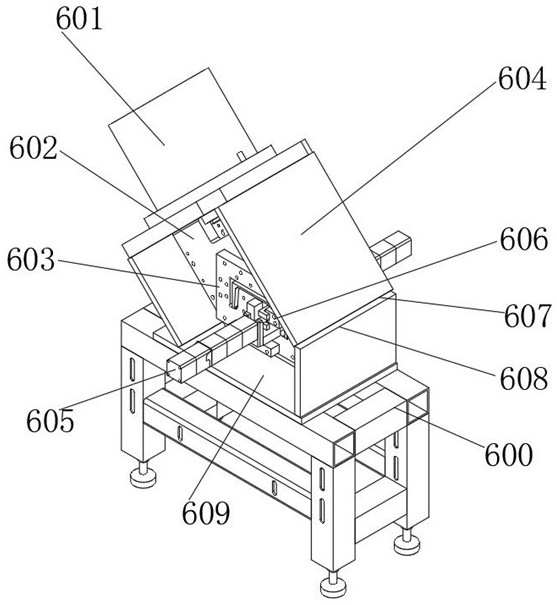

[0068] The functional units involved in this application can be combined flexibly, with or without, each functional unit can be one or several, and the positional relationship between them can be exchanged with each other, and they can be matched according to actual usage conditions, so as to adapt to change This is also the key point of the machine invented by this patent. In this patent, each functional unit is separated into independent functional units, and a long shape is processed on the four columns of the frame and the beam. According to the actual needs, the user can connect the functional units together with bolts through these holes to form different models that meet the actual needs. There are adjusting nuts and adjusting screws on the four outer feet of each rack. For the side pressure frame, there are nuts and adjusting screws under the two columns. By adjusting the screws and nuts, different functional units can be adjusted. The high position is suitable for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com