Processing and detecting method for end face deep annular groove

A detection method and annular groove technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as difficulty in improving production efficiency, restricting production efficiency and batch requirements, and difficulty in dimensional accuracy control, and reducing Requirements for operating skills, stable and reliable product quality, and the effect of reducing the number of trial cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0031] 1. The design idea of the present invention is as follows:

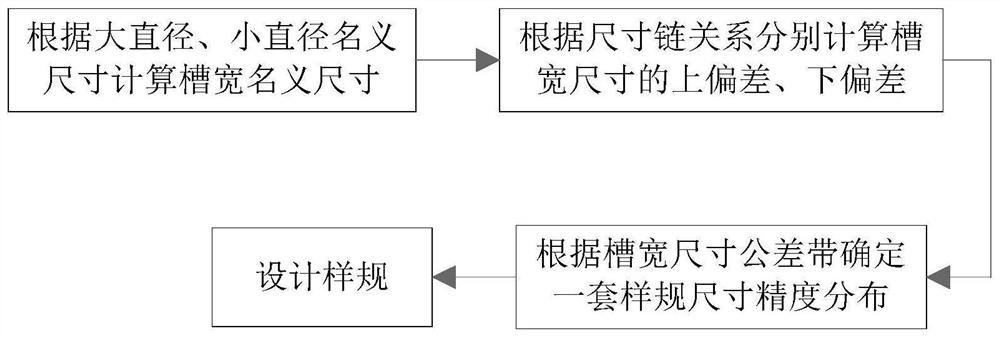

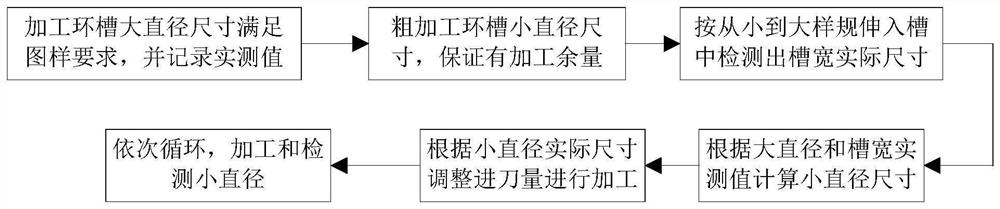

[0032] a) Change the traditional thinking mode and re-determine the dimensional chain relationship of the annular groove.

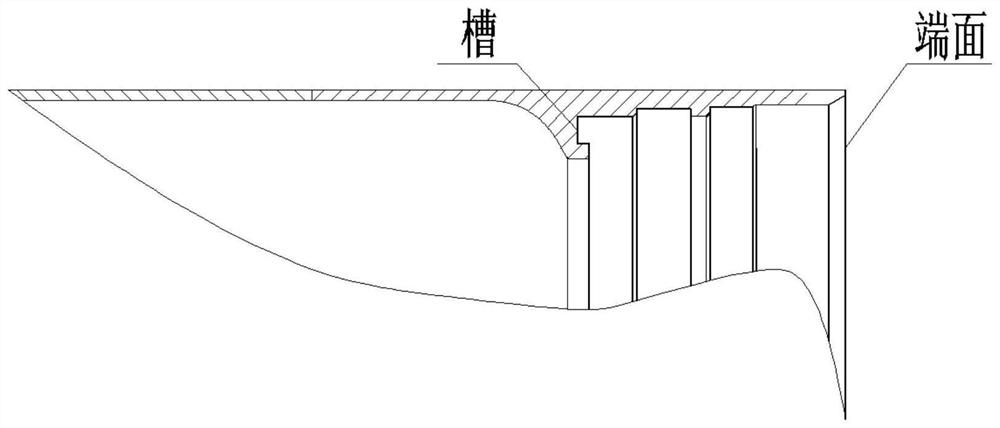

[0033] The current process method is to ensure the two diameters of the annular groove according to the dimension requirements of the drawing. The small diameter cannot be directly measured, but it must be guaranteed. Therefore, according to the logical relationship of the size chain, the small diameter should be the closed-loop size of the size chain (A0 ), the major diameter size and the groove width size are the open loop size (A1, A2) of the size chain respectively. Calculate the groove width size and tolerance through the two known diameter dimensions and the dimension chain of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com